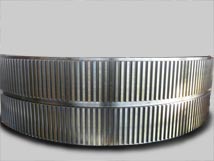

ball mill large gear

Ball mill gear adopt the automatic oil injection lubrication device, grease injection of gear meshing place to enter. The improved only will automatically nozzle head moved to gear meshing burning, fixed in the tooth hood, and completes the tubing connection. In order to prevent tooth cover vibration on line, and the influence of nozzle head and for oil circuit system had better choose a section hose. Grease in gear into the meshing former timing injection, timely were brought into tooth room extrusion, glued to the tooth surface forming oil film, improve the gear lubrication condition, and can prevent grease splash. This effectively prolong the operating life of the gear, and save the grease.

Other supplier products

|

|

ф5650 half a gear |

We have a 30 ton’s electric are, a 3 ton’s intermediate frequency furnace, laboratory equipment Shimadzu optical spectrometer, 5.5*6.5*3m gas leer... |

|

|

ball mill end cap |

Ball mill shell cover have welding and casting two kinds of structure. Welding plate is

steel plate direct welding in the cylinder body, ma... |

|

|

cone crusher parts |

Cone crusher work features:

1) moving cone continuous rotation, and the material of the crushing process and discharge process along the work su... |

|

|

ball mill feed end cap-1 |

The structural features of the ball mill:

This ball mill is made up of feeding part, discharging part, gyre part, transmission part (decelerator... |

|

|

ball mill large gear |

Ball mill gear adopt the automatic oil injection lubrication device, grease injection of gear meshing place to enter. The improved only will autom... |

All supplier products

Same products