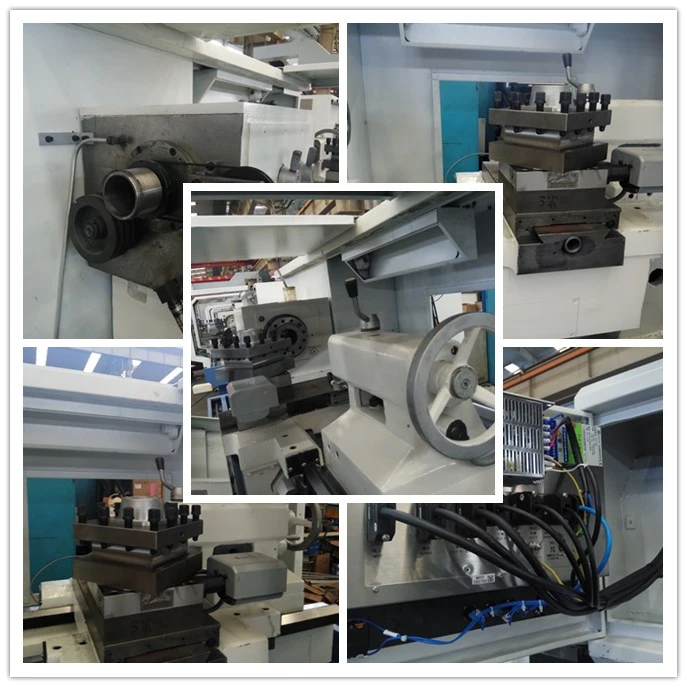

Chinese CKH61200 heavy duty lathe machine with good service

Chinese heavy duty lathe machine with good service

This machine not only processing a variety of shaft, disk type parts and turning all kinds of thread, conical and cylindrical inner and outer surfaces, but also widely used for cutting ferrous metal and nonferrous metal .

Main configuration:

1.The control system uses a wide number of funuc oi-TF (5 package).

2.1.5 m, 3 m X / Z motor with funuc feed servo motor 20Nm; 5 m, 6 m X / Z 3.motor 20 / 36Nm.

4.The main motor adopts Beijing super synchronous servo motor 30kw.

5.Shenyang vertical 4-station electric knife

6.Electrical components Schneider

7.Manual four files within the stepless speed.

Other configuration:

1.Rail width of 755, load-bearing 6 tons, can change the weight of 8 tons

2.Without semi-protection. Increase the cost of another

3.Can be added chip machine. Increase the cost of another

4.5 meters above the lead with a screw support

5.Can be changed to the overall bedside box structure plus money

6.The air box does not have air conditioning

|

UNIT |

CKH61200 |

||

|

CAPACITIES |

Swing over bed |

mm |

2000 |

|

Swing over carriage |

mm |

1600 |

|

|

Max.length of workpiece |

mm |

10000 |

|

|

Max.turning length |

mm |

9800 |

|

|

Pan of guideway |

mm |

1100 |

|

|

SPINDLE |

Spindle nose |

A2-15 |

|

|

Spindle bore |

mm |

100 |

|

|

Taper hole of spindle |

140 |

||

|

Range of spindle speeds |

r/min |

3~320 |

|

|

No.of spindle speeds |

Stepless speed change |

||

|

Max. weight of workpiece |

t |

16 |

|

|

Chuck |

mm |

1600 |

|

|

FEED |

Max.cutting power |

N |

39200 |

|

Rapid speeds |

mm/min |

4000/6000 |

|

|

Max.travel |

mm |

850 |

|

|

TURRET |

Turret working position |

V4 |

|

|

Size of turret |

mm |

380X380 |

|

|

Max. feed force Py |

N |

10875 |

|

|

Section of tool shank |

mm |

50X50 |

|

|

TAILSTOCK |

Dia. of tailstock quill |

mm |

260/300 |

|

Travel of tailstock quill |

mm |

160/300 |

|

|

Taperhole of tailstock |

80 |

||

|

OTHERS |

Workpiece accuracy |

IT7 |

|

|

Surface roughness |

μm |

Ra2.5~3.2 |

|

|

Main power |

kw |

22 |

|

|

Lathe mass |

kg |

30400 |

|

|

Length |

mm |

13400 |

|

|

Width/Height |

mm |

2950/2950 |

|

|

CNC System |

FANUC Series0i-mate-TD/0i-TD |

||

also called headstock, it is the main task of the main motor rotation movement coming after a series of variable speed institutions make main shaft gets the different rotating speed of the positive and negative two turn, at the same time the spindle box gives impetus to the movement into the box.

there are two layers of skateboard (medium, small skateboard), the saddle and the frame body together. Used to install the lathe tool and drive the lathe tool for longitudinal, transverse or oblique movement.

When the gear and gear ring are engaged, the four locking claws are connected, synchronously and at the same time, can hold the circular workpiece.When the gear and gear ring are separated, the four claws are independent, which are the same as the original four-jaw chuck,which are used for holding square workpieces to achieve the purpose of general purpose, which has the advantages of simple structure and convenient use.

Pre -Sale

♠Accordingtoclientsrequirement(Purchasepurpose),wecanofferserviceasfollowing:

♠Projectsystemevaluationinvestmentbudget

♠Sitemeasurement

♠Technicaldiscussion

♠Supplyprofessionaldrawingandlists

In-sale

♠Qualityguaranteed

♠Fieldserviceforequipmentinstallationandtrainingwork

♠Acceptanceanddelivery

Afer-sale

♠24honineresponse

♠Supplyingsparepartsatcostprice

♠Regularreturnvisit

Send product request

Other supplier products

| Swing over bed C61200 heavy duty lathe with good service | Swing over bed C61200 heavy duty lathe with good service This machine tool belongs to heavy machine tool, the maximum weight is 16 tons, adopt t... | |

| drill rod end forging machine for Upset Forging of oil pipe end | DRILL PIPE PRODUCTION LINE: The production line for the processing and production of oil drilling pipe, is mainly divided into three steps, by usi... | |

| universal cnc mini lathe for sprinkler | The Horizontal bench lathe machine SK0632 can achieve automatic control, automatically process a variety of parts of the inner and outer ring, end ... | |

| oil casing tube forging upsetter for Upset Forging of oil pipes casing tubing | DRILL PIPE PRODUCTION LINE: The production line for the processing and production of oil drilling pipe, is mainly divided into three steps, by usi... | |

| oil pipe production line for Upset Forging of drill pipe | DRILL PIPE PRODUCTION LINE: The production line for the processing and production of oil drilling pipe, is mainly divided into three steps, by usi... |

Same products

| Point Rails Lowering Value Measuring Ruler | Seller: 842518 | The frog vertical wear measuring ruler is used to measure the vertical wear value at any part of ... | |

| Portable Laser Alignment Device | Seller: 842518 | Laser Alignment Device is used for measuring track level and line to aid track measurement and ha... | |

| Rail cant measurement device | Seller: 842518 | The main part of the wheel tread is an inward inclination of 1:40 . In order to make the top of t... | |

| NGM-6.3II Internal Combustion Rail Grinding Machine | Seller: 842518 | This machine is mainly used for the recovery and grinding of welded joints,calendering burrs,rail... | |

| NCM-5.1 Internal Combustion Turnout Grinding Machine | Seller: 842518 | NCM-5.1 frog and switch grinder is specifically designed for grinding operations through switch a... |