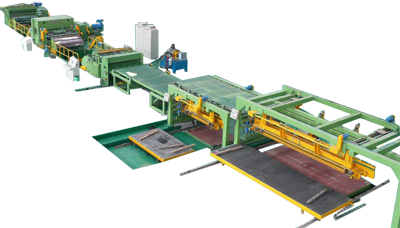

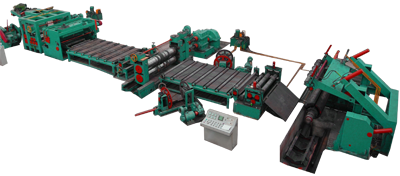

Light Gauge Cut To Length Lines

Cut To Length line is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to length and blanking. RISHBIN supply full range of cut to length line according to client’s special requirement by combining different component. Every CTL line is engineered and constructed differently for customers, it is customized designed and built, it is considered when choosing a right CTL line about some specifics like production capacity, running speed, material thickness and width, etc. Quality and standard checks are strictly performed on our product before releasing to our valued customers.

Available raw material for cut to length line is hot rolled steel, cold rolled steel, galvanized steel, pre-painted steel, high tensile steel, stainless steel, aluminum, copper, alloys.

Main Technical Parameters of Light Gauge Cut To Length Lines

RISHBIN light gauge automatic cut to lengthmachines are built for speed and ease of use and can produce higher line speeds without experiencing material slippage. Light gauge lines are also capable of processing surface critical material without marking. Cut-To-Length Line and Blanking Line will make your job easier, cut costs, and increase your profits.

The cut to length line for saleon Rishbin can be supplied with start-stop shears, flying shears, rotating shears or continuous direct feed. High-precision levelers of four, five and six heights, computer controlled. Edge trimming may be incorporated.And the cut to length machine priceis reasonablie.

Here is working process:

Steel coils are transferred by an entry coil car and loaded onto an uncoiler. From uncoiler the strip proceeds through a five-high precision leveler designed to level steel within the desired material gauge range and yield strength. The strip then proceeds through a squaring unit and precision roll-feed unit to the high speed shear, where it is cut to required length. The cut sheet then moves to float sheet stacker where it is stacked on a pallet and is then moved onto the semiautomatic packaging line for wrapping.

|

Model |

RS-1.2 |

RS-2.0 |

RS-3.0 |

RS-4.0 |

|

CoilMaterial |

δs≤230N/mm2,Cold-rolledCoil,StainlessSteelCoil,GalvanizedCoil,AL,Copper |

|||

|

CoilThickness |

||||

|

CoilWidth |

300~800mm |

800~1250mm |

800~1250/1600mm800~1600/1800mm |

|

|

CoilWeight |

≤10T |

≤20T |

≤20T (25T) ≤25T (30T) |

|

|

CoilI.D |

ф508mm |

ф508mm |

ф508&ф610mmф508&ф610mm |

|

|

OD coil |

≤ф1800mm |

≤ф1800mm |

≤ф2000mm ≤ф2000mm |

|

|

CuttingRange |

300~3000mm |

300~4000mm |

300~4000mm300~4000mm |

|

|

CuttingAccuracy |

± 0.3mm |

± 0.3mm |

±0.5mm±0.5mm |

|

|

RollerDiameter |

f65 (50) |

f65 (50) |

F 85 (65) F 100 (80) |

|

|

LinearSpeed |

0 ~ 60m / min |

0 ~ 60m / min |

0 ~ 60m / min 0 ~ 60m / min |

|

|

ControlSystem |

PLCAutomaticcontrol |

PLCAutomaticcontrol |

PLCAutomaticcontrolPLCAutomaticcontrol |

|

Rishbin was founded in 1999. With almost twenty years development, now it becomes a leading professional supplier in the field of steel slitting line machineindustry, and exports its quality production line to the markets all over the world.We sincerely invite and welcome people from all around the world to invest and create more values together.

Send product request

Other supplier products

| Steel Sheet Slitting Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Metal steel sheet slitting machine main types:... | |

| Light Gauge Slitting Lines | RISHBIN Light Gaugesheet metal slitter machinefor pre-painted/coated coils, max. thickness of up to 3mm, max. width of up to 2200mm, and speed of u... | |

| Rotary Shear Cut To Length Lines | Rotary Shear Lines are mainly used for CR, S.S, Al material, precision leveling and cutting products. This line special advantage is non-stop cutti... | |

| Heavy Gauge Slitting Lines | Machine Reviews RISHBIN Heavy Gauge Slitters are designed to slit high strength heavy gauge materials. Coils max. thickness of up to 20mm, max. wid... | |

| Steel Slitting Line/Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Operating Procedure of Preparatory work befor... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |