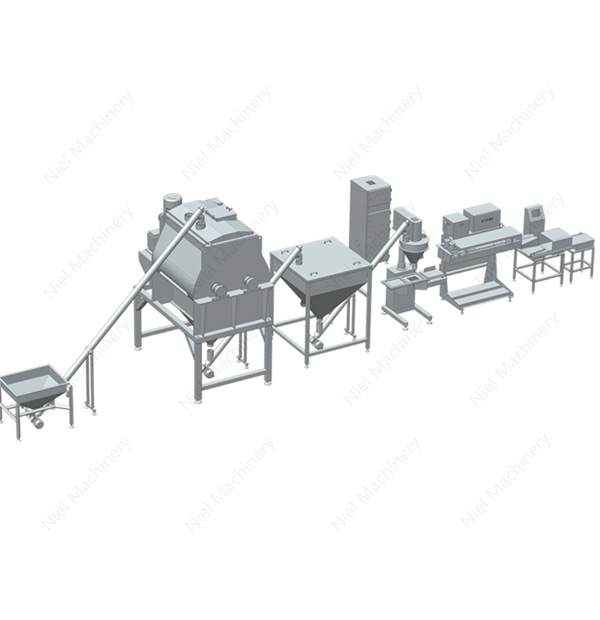

Pulling Type Paddle Mixer

The pulling type paddle mixer machineis mainly used for anti-cracking mortar, thermal insulation mortar, bonding mortar, plastering mortar, floor mortar and other dry powder mortars with high mixing uniformity and high-grade putty powder. Concrete admixtures, feeds, chemical powders, food flavors and other industries have also been greatly applied, and it is not suitable for the mixing of raw materials with a particularly large amount of spray and particularly large viscosity of materials.

Product Description of Pulling Type Paddle Mixer Machine

Pulling type paddle mixer machine is widely used for drying and mixing of dry powder mortar, chemical, pesticide, detergent, pigment food, monosodium glutamate, milk powder, salt, feed, chemicals, ceramics, plastics, rubber additives, and other powders.

Pulling type paddle mixer machine is also called a non-gravity door open type mixer. Based on the long-term practice in the field of mixers, the equipment overcomes the shortcomings of horizontal mixer cleaning and uses gear reduction gearbox and mixer rotor direct connection transmission for higher reliability and longer service life.

Structural Characteristics of Pulling Type Paddle Mixer Machine

The right end surface of the pulling type paddle mixer machine body is provided with a non-drive endplate, the left end is provided with a drive endplate, the lower end of the drive end plate is disposed inside the track, and the motor reducer and the rotor shaft are respectively provided with two, the left end of the rotor shaft and the output end of the motor reducer is connected and connected, and the rotor shaft is assembled inside the mixer body through the driving endplate. The rotor shaft is symmetrically arranged inside the mixer body, the blade is assembled on the rotor shaft, and the track is arranged on the lower side of the mixer body. The lower end opens a discharge door, and a shaft seal is arranged at a connection between the rotor shaft and the output end of the motor reducer.

The Pulling type paddle mixer machine is a new high-efficiency material mixer independently developed and designed by the Neil mechanical design team based on the twin-blade gravity-free mixer. This model maintains the advantages of the previous generation double-mix mixer. On the basis of the design of the side-opening door, the cleaning efficiency and mixing speed are greatly improved, the mixing time is shortened, and the production efficiency is greatly improved.

Application of Pulling Type Paddle Mixer

Dry mortar

Chemicals, chemicals, detergents,

Feed, pesticides,

Pigment food, monosodium glutamate, milk powder, salt

Ceramic, plastic, rubber additives

Main Features of Pulling Type Paddle Mixer

(1) Easy to clean, side-opening door design makes machine cleaning more convenient and saves production time

(2) The rotation speed of the shaft driven by the reducer and the structure of the blade will weaken the gravity of the material. With the lack of gravity, the difference in particle size and a specific gravity of each material is neglected during the mixing process.

(3) The intense mixing movement shortens the mixing time, which is faster and more efficient.

(4) Even if the material has a difference in specific gravity and particle size, a good mixing effect can be achieved under the rapid and vigorous tumbling of the staggered stirring blades.

Technical Data of Pulling Type Paddle Mixer

|

Technical Data |

||||||

|

Model no. |

Effective Vol |

Loading ratio |

Power |

Speed |

Dimension (mm) |

Weight |

|

NCL-300 |

300L |

4KW |

53r/min |

3240X1035X1430 |

580kg |

|

|

NCL-500 |

500L |

53r/min |

3390X1160X1480 |

860kg |

||

|

NCL-1000 |

1000L |

11KW |

45r/min |

3590X1380X1630 |

1530kg |

|

|

NCL-1500 |

1500L |

15KW |

45r/min |

3880X1550X1810 |

1980kg |

|

|

NCL-2000 |

2000L |

39r/min |

4180X1780X1930 |

2590kg |

||

|

NCL-3000 |

3000L |

22KW |

31r/min |

4430X1910X2040 |

3620kg |

|

|

Power supply |

AC 3 Phase 208-415V 50/60HZ |

|||||

Our company provides paddle type mixer,horizontal powder mixer,paddle mixer design,horizontal paddle mixer,paddle mixers for saleand bulk powder transport,RFQ today.

Send product request

Other supplier products

| Powder Filling Packing Machine | The vertical packing machinerefers to machinery that can complete all or part of the product and product packaging process. The packaging process i... | |

| Pulse Jet Dust Collector | This pulse jet dust collectoris a new type of dust collector developed on the basis of our company's first generation dust collector. The stainless... | |

| Laboratory Mixer Machine | The laboratory mixer machine automatically performs all movements such as clamping, rotation, and mixing. Equipped with a series of automatic lifti... | |

| Post Lifting Bin Mixer | The post lifting bin mixer can automatically complete the functions of lifting, mixing and lowering, and is ideal mixing equipment for the solid pr... | |

| Powder Mixing And Bag Filling Packing Line | This powder production line is relatively simple in design and is a typical small and medium-sized powder packaging production line. It is suitable... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |