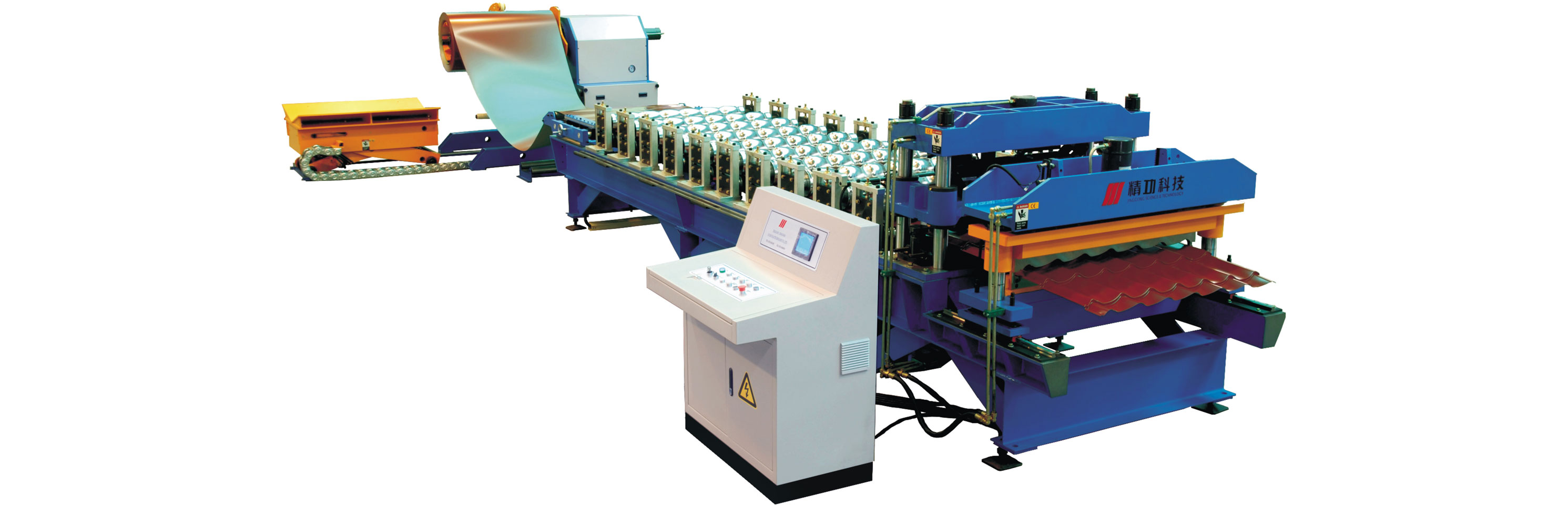

High Speed Tile Forming Machine

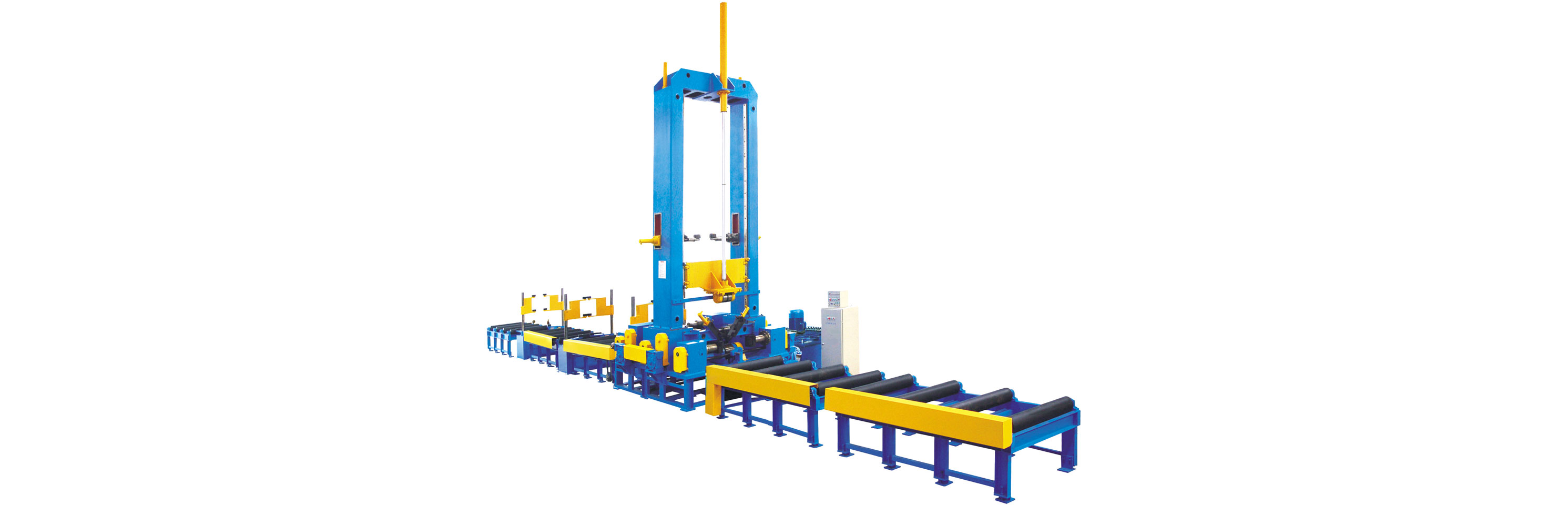

This series of high-speed tile roll forming machine is a new-generational type roof tile forming machinewith high speed and high-efficient, including decoiler system, sheet guiding system, roll forming system, pressing system, cutting system, auto-stacker system, hydraulic system, controlling system, etc.

The common thickness for final products is normally 0.4-0.8mm to different profiles and materials.We also have otherglazed tile roll forming machine, like the ridge cap and downpipe machines for roof use.

High-speed roof tile roll forming machine for saleon jinggongmachine.com, contact us right now!

Jinggongtile roll forming machine is one professional equipment to produce steel tile, which is comprehensively used in the large and medium-sized houses, villas, etc.

This line includes uncoiler, coil sheet guiding, roll forming, punching, post-cutting, hydraulic system, controlling system, and etc.

Technical Parameter Of High Speed Roll Forming Machine

|

Item |

parameter |

|

|

Modle |

HVM-183 |

|

|

Material |

Type |

Colored steel sheet |

|

Thickness |

||

|

Yield strength |

230-300 |

|

|

4-5 |

||

|

Roller material |

45#Steel with chrome coated |

|

|

Roller driven type |

Chain transmission |

|

|

Controller |

PLC |

|

|

Operation |

Touch screen+button |

|

|

Hydraulic system pressure |

13 |

|

|

Hydraulic station motor power |

||

|

Main motor power |

4 |

|

|

Total power |

||

|

Total weight |

About 10000 |

|

Technic Flow Of High-Speed Tile Forming Machine

Decoiling→guiding and feeding→roll forming→pressing→cut to length→run out table

Main Components of High-Speed Tile Forming Machine

Uncoiler

Cantilever-type fully automatic uncoiler adopts ultrasonic sensor technology and frequency inverter adjustment. The pressing-arm hydraulic driven power is optional. All electrical parts and hydraulic parts are installed inside of uncoiler frame.

Roll forming

Roll forming system consists of guiding device, machine base, transmission parts. and roll forming rollers, etc. The filming and pre-slitter device is optional.

Punching

The punching system adopts hydraulic type punching, which works stably and without scratch. The single punching or twin punching is optional.

Post-shearing device

Post-shearing device adopts frame type hydraulic shearing. The panel is cut stably and can avoid distortion. This design don't have any scrap in the process of cutting.

Hydraulic system

Hydraulic system is installed inside of machine base. The design is reasonable and compactly.

Controller

It adopts Mitsubishi PLC and frequency inverter adjustment to realize fully automatic operation. Operator can set parameters such as badges, length of panels quantities in the touch screen.

Jinggongis a professional roll forming machine company, we provide continuous sandwich panel line, roll forming machine for sale, flame cutting machine for sale, etc.Want to know roofing roll forming machine priceor more, contact us.

Send product request

Other supplier products

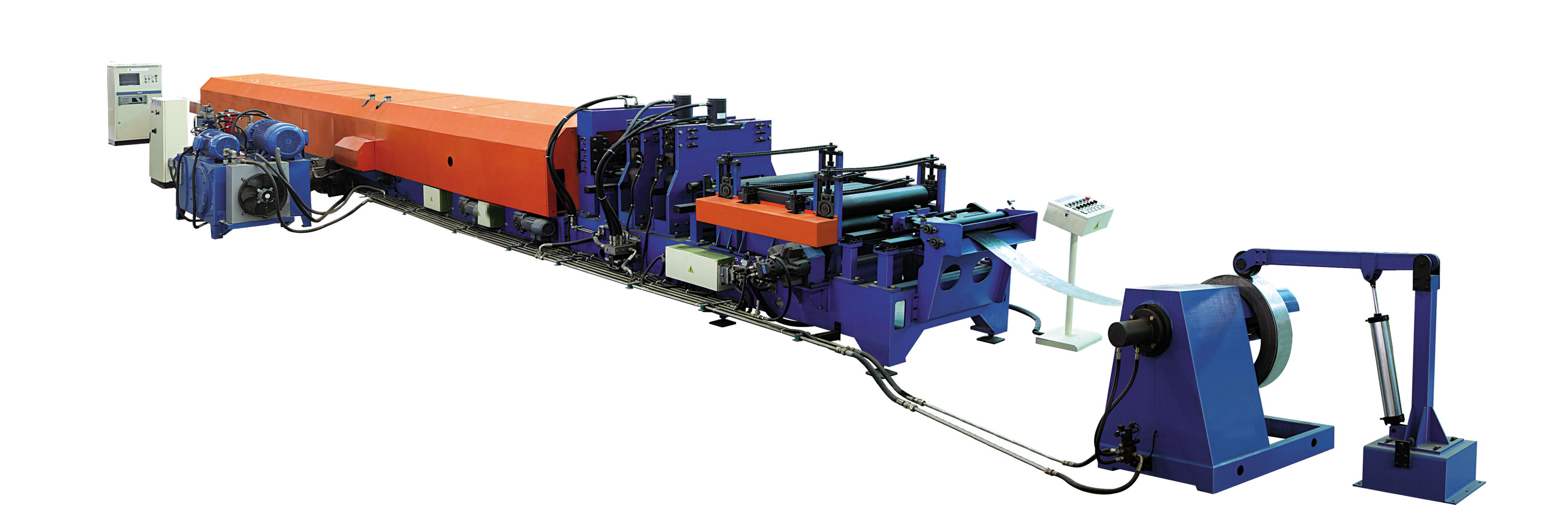

| C&Z Changeable Purlin Forming Machine | The control system ofC&Z purlin forming machineincludes an industrial computer, communicating with PLC through RS485 connector. The system adop... | |

| Basic Situation of the Building Materials Machinery Industry | Ⅰ. Basic situation of the industry economy In the face of fierce market competition, the building materials machineryindustry has seen positive ... | |

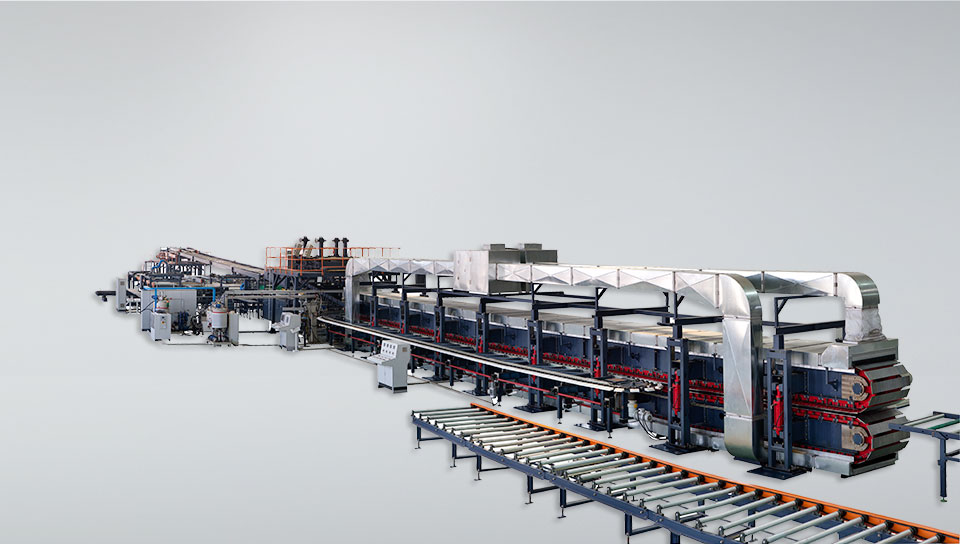

| EPS Sandwich Panel Production Line | Main structure features ofEPS Sandwich PanelMachine 1) This EPS sandwich panel making machinehas the specification: nice appearance, low noise and... | |

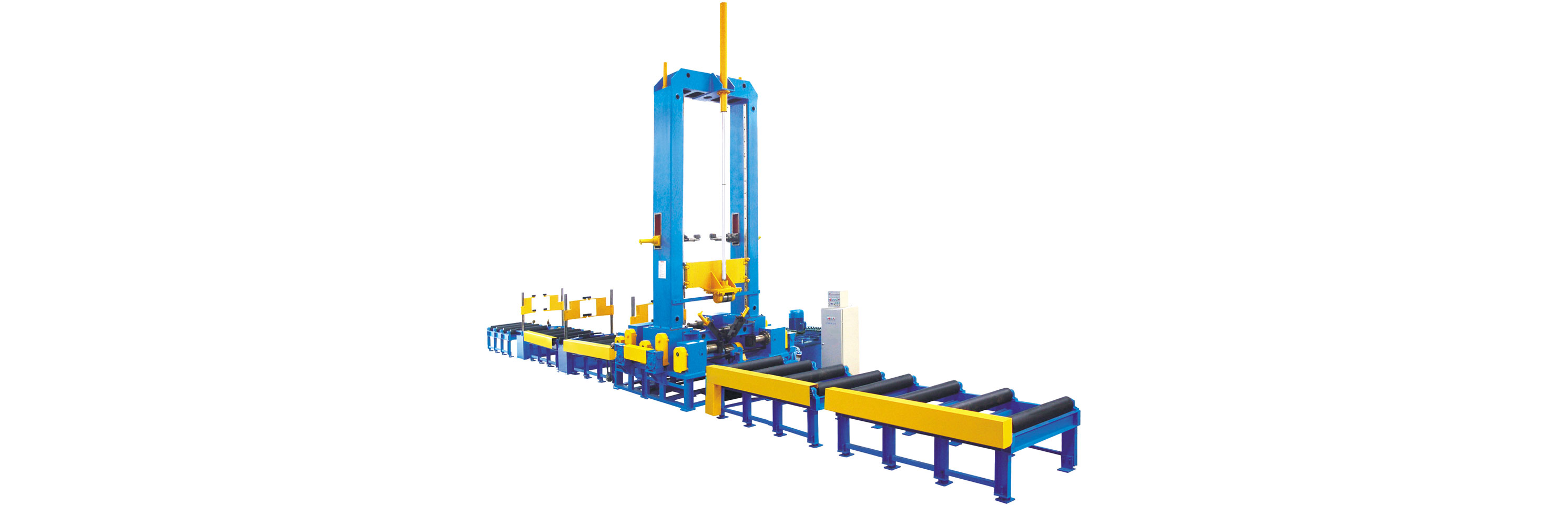

| H-Beam Assembling Machine | The clamping and alignment of the web plate and flange plate will be done in H-Beam Assembling Machine, there also have automatic tack-welding. Jin... | |

| H-Beam Assembling Machine | The clamping and alignment of the web plate and flange plate will be done in h beam assembly machine, there also have automatic tack-welding. Jingg... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |