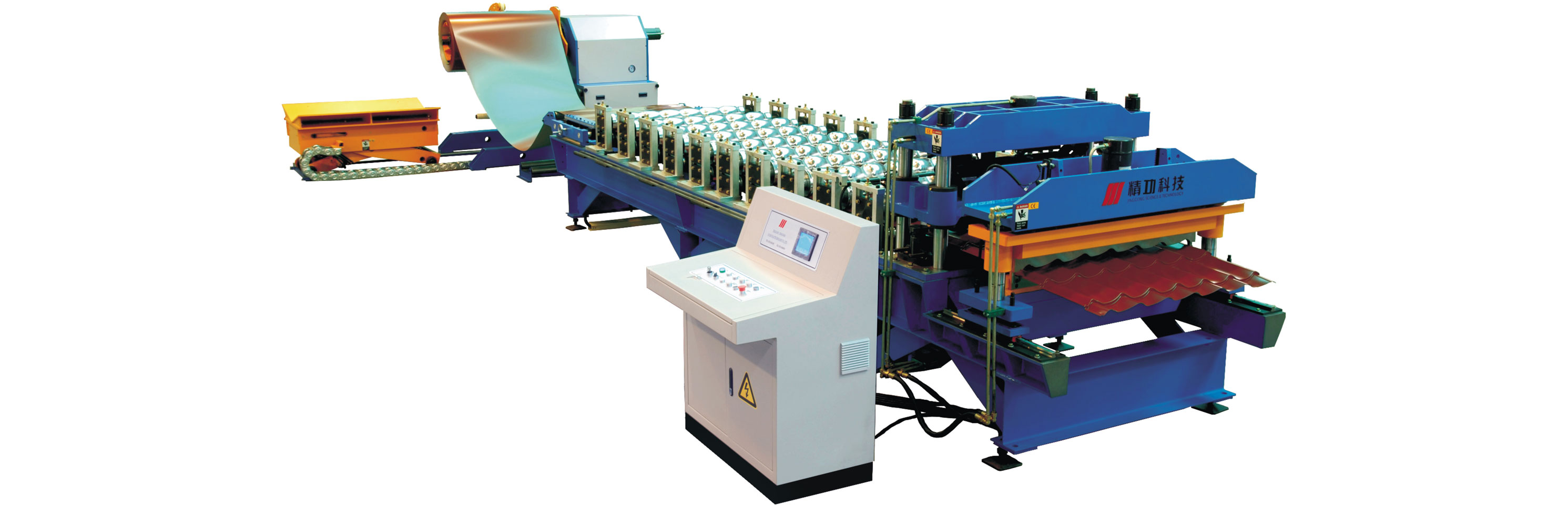

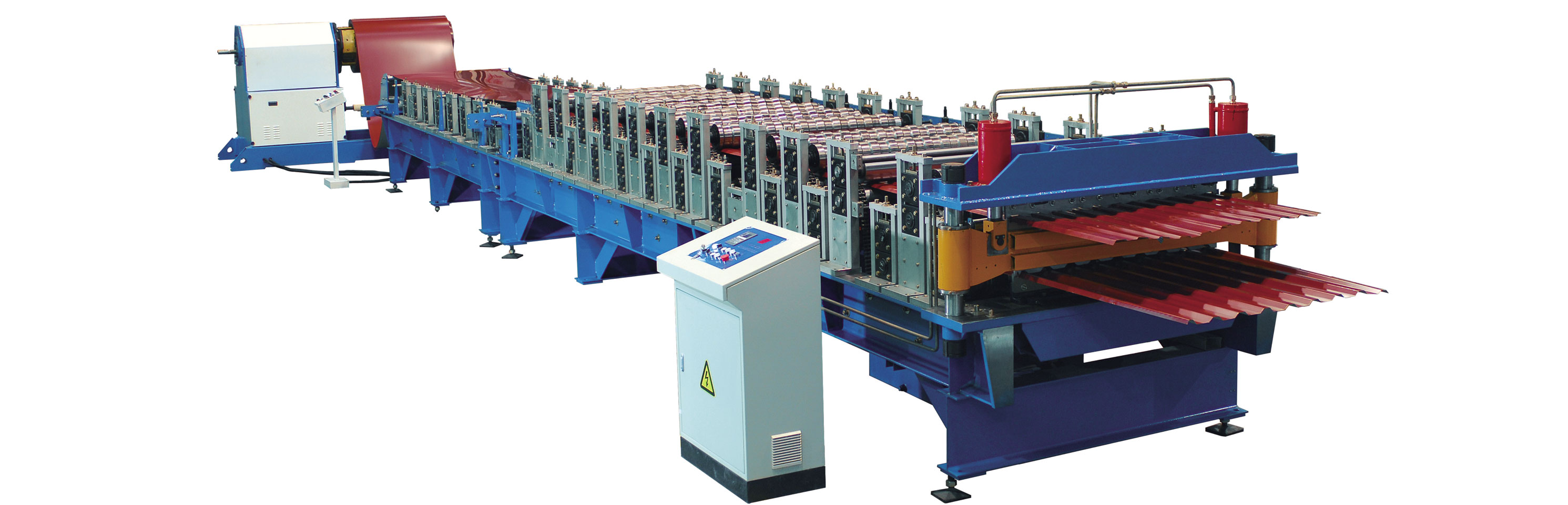

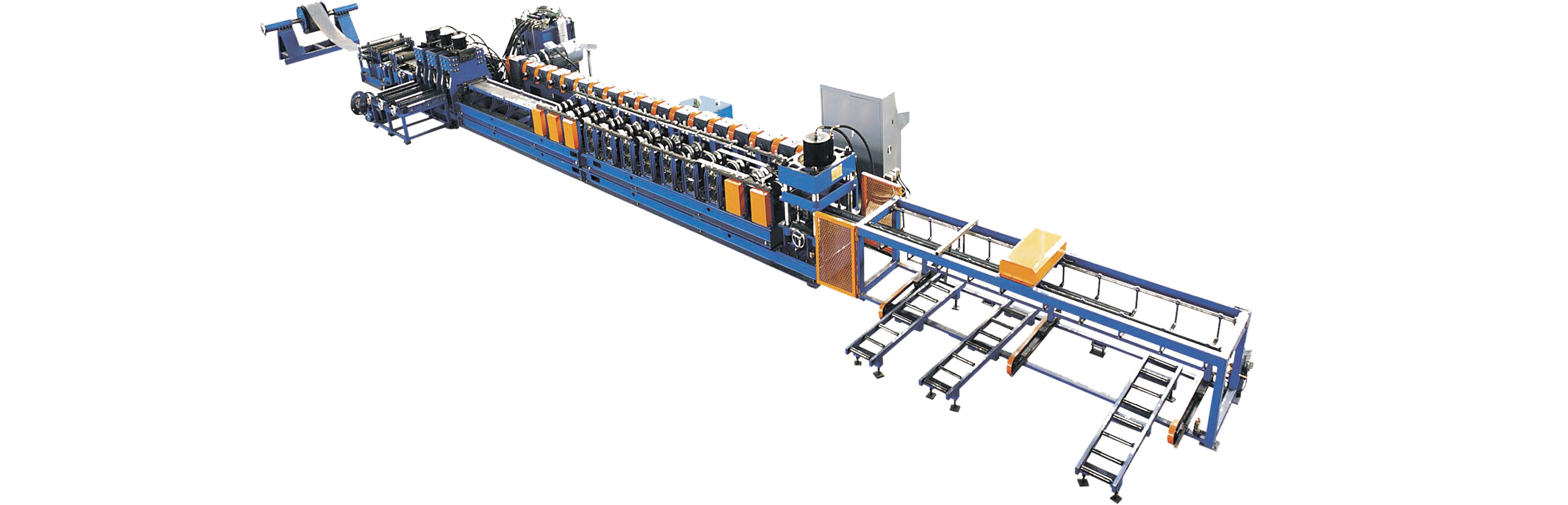

High Speed Tile Forming Machine

This series of high-speed tile roll forming machine is a new-generational type roof tile forming machinewith high speed and high-efficient, including decoiler system, sheet guiding system, roll forming system, pressing system, cutting system, auto-stacker system, hydraulic system, controlling system, etc.

The common thickness for final products is normally 0.4-0.8mm to different profiles and materials.We also have otherglazed tile roll forming machine, like the ridge cap and downpipe machines for roof use.

High-speed roof tile roll forming machine for saleon jinggongmachine.com, contact us right now!

Jinggongtile roll forming machine is one professional equipment to produce steel tile, which is comprehensively used in the large and medium-sized houses, villas, etc.

This line includes uncoiler, coil sheet guiding, roll forming, punching, post-cutting, hydraulic system, controlling system, and etc.

Technical Parameter Of High Speed Roll Forming Machine

|

Item |

parameter |

|

|

Modle |

HVM-183 |

|

|

Material |

Type |

Colored steel sheet |

|

Thickness |

||

|

Yield strength |

230-300 |

|

|

4-5 |

||

|

Roller material |

45#Steel with chrome coated |

|

|

Roller driven type |

Chain transmission |

|

|

Controller |

PLC |

|

|

Operation |

Touch screen+button |

|

|

Hydraulic system pressure |

13 |

|

|

Hydraulic station motor power |

||

|

Main motor power |

4 |

|

|

Total power |

||

|

Total weight |

About 10000 |

|

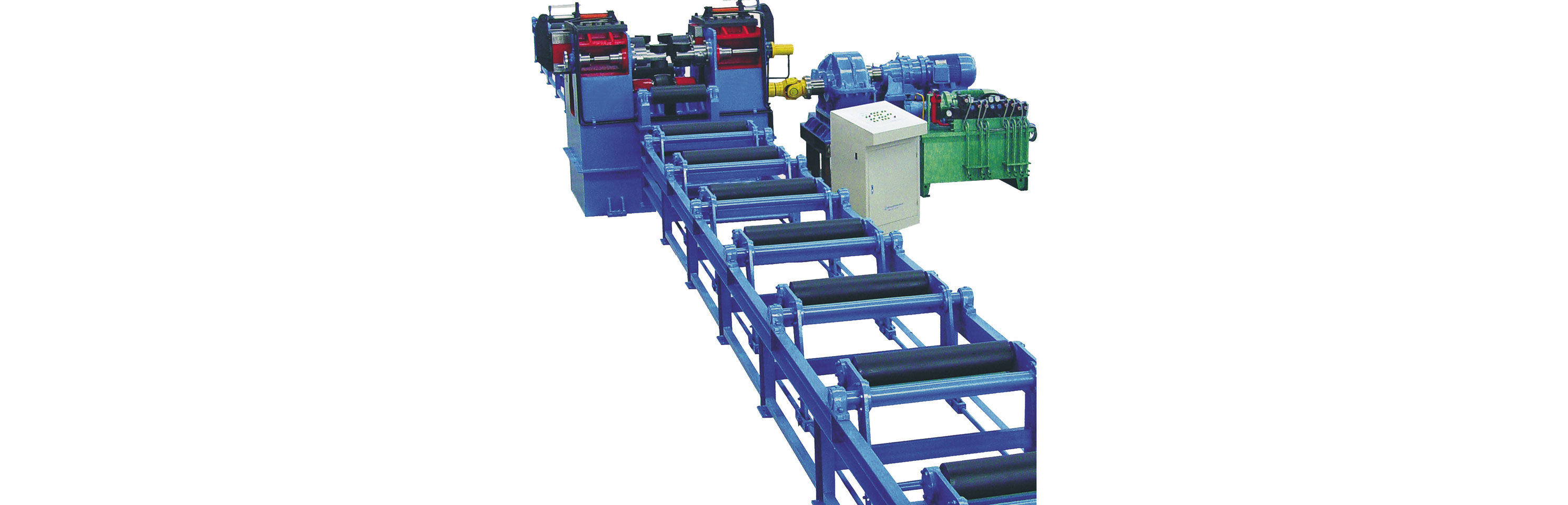

Technic Flow Of High-Speed Tile Forming Machine

Decoiling→guiding and feeding→roll forming→pressing→cut to length→run out table

Main Components of High-Speed Tile Forming Machine

Uncoiler

Cantilever-type fully automatic uncoiler adopts ultrasonic sensor technology and frequency inverter adjustment. The pressing-arm hydraulic driven power is optional. All electrical parts and hydraulic parts are installed inside of uncoiler frame.

Roll forming

Roll forming system consists of guiding device, machine base, transmission parts. and roll forming rollers, etc. The filming and pre-slitter device is optional.

Punching

The punching system adopts hydraulic type punching, which works stably and without scratch. The single punching or twin punching is optional.

Post-shearing device

Post-shearing device adopts frame type hydraulic shearing. The panel is cut stably and can avoid distortion. This design don't have any scrap in the process of cutting.

Hydraulic system

Hydraulic system is installed inside of machine base. The design is reasonable and compactly.

Controller

It adopts Mitsubishi PLC and frequency inverter adjustment to realize fully automatic operation. Operator can set parameters such as badges, length of panels quantities in the touch screen.

Jinggongis a professional roll forming machine company, we provide continuous sandwich panel line, roll forming machine for sale, flame cutting machine for sale, etc.Want to know roofing roll forming machine priceor more, contact us.

在线联系供应商

Other supplier products

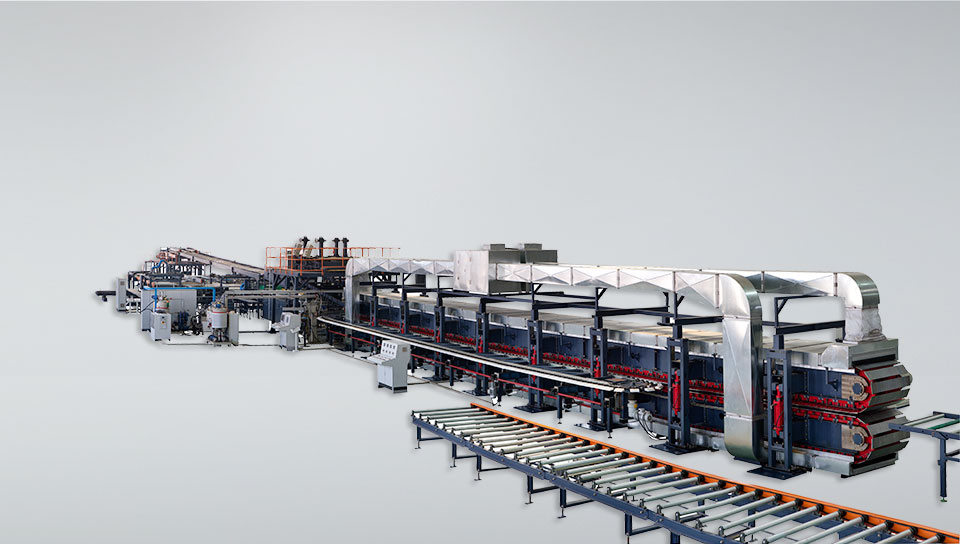

| EPS Sandwich Panel Production Line | Main structure features ofEPS Sandwich PanelMachine 1) This EPS sandwich panel making machinehas the specification: nice appearance, low noise and... | |

| High Speed Roll Forming Machine | The high speed formingmachine is the new type line which is produced both by our company and Formia company from Finland. The complete machine adop... | |

| H-Beam Straightening Machine | H-Beam StraighteningMachine is mainly used for the angle distortion straightening of heavy H-beam, it adopts hydraulic straightening which will hav... | |

| Basic Situation of the Building Materials Machinery Industry | Ⅰ. Basic situation of the industry economy In the face of fierce market competition, the building materials machineryindustry has seen positive a... | |

| Guardrail Roll Forming Machine | Guardrail Forming Machineis the special forming equipment for producing the speedway guide rail. One shift every month can produce 600 tons (max). ... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |