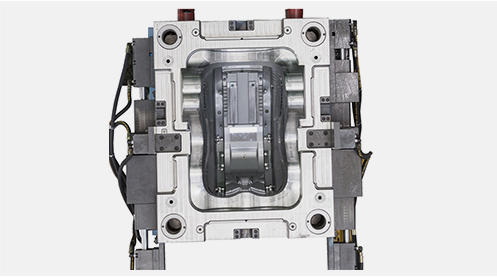

Plastic Connector Mould with Brass Molding Inserts

In order to meet the needs of installation and connection, or to increase the strength of the plastic part, suitable metal parts are designed to insert into plastic molding parts, making an integrated products of both metal and plastic.

The connector is designed with brass insert, it is a good insulator with better strength, so it is applied for electronic and electrical power components, machinery and equipment installation.

High-quality brass inserts for injection molding

This mold is multi-cavities 1*2. The insert positioning block for the copper can be taken out and put in easily from the cavities. The brass insert was preheated to ensure a uniform temperature in the mold cavities.

Basic Information for Connector with Brass

Benefits of Plastic Connector Molded with Brass Insert

Plastic molding part with metal material insert provides you additional functions, you can obtain great advantages including:

It is of electric conduction with brass insert for electronic devices electrical equipment.

To design with screw thread section on the metal, it can be installed to devices and equipment very conveniently.

With metal insert, it enhances the strength of the plastic molding connector.

It is of electrical insulation and heat insulation for safety sake.

With low-level noise.

How To Design A Connector With Metal Insert

Select metal materials with a small coefficient of thermal expansion as inlay materials, such as brass, aluminum, aluminum alloy, etc.

The metal design shall not have sharp corners, and shall be properly rounded to improve the plastic strength. The surface of the insert should preferably be provided with exquisite rolling patterns or grooves to increase the friction.

The plastic thickness around the metal insert shall be sufficient. For example, the plastic thickness around the insert is "h", the outer diameter of the metal insert is "D", the plastic thickness for the aluminum insert should be h ≥ 0.8D, and the plastic thickness for the brass insert should be h ≥ 0.9D.

Green Vitality Industry is a professional injection molding factoryin various industries since 1993. We provide metal insert moulding, plastic insert moulding, brass molding inserts, metal insert molding, injection moldand etc. Want to know more, contact us.

Send product request

Other supplier products

| Car Seat Mould for Kids | Child safety mouldy car seatsare seats specially designed to protect children from injury or death in a collision. The main structure of the child ... | |

| LCD TV Mould | TV screen frame mold is used to produce TV screen frames, it should be strong and assembly well with the screen. It has an undercut to lock the scr... | |

| Plastic Gear Mold | Injection molded plastic gearsis one of the most widely used transmission mechanisms in the field of instruments & meters, timers, reducers, ca... | |

| Industrial Plastic Injection Mold | Industrial Plastic Injection Mold The industrial mouldingpart is replacing metal products in many fields of industrial applications to meet the ... | |

| Plastic Toilet Seat Mold |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Seller: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |