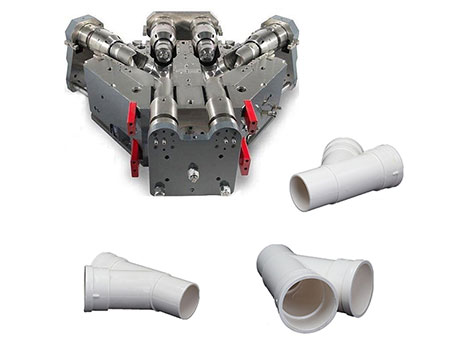

Plastic Connector Mould with Brass Molding Inserts

In order to meet the needs of installation and connection, or to increase the strength of the plastic part, suitable metal parts are designed to insert into plastic molding parts, making an integrated products of both metal and plastic.

The connector is designed with brass insert, it is a good insulator with better strength, so it is applied for electronic and electrical power components, machinery and equipment installation.

High-quality brass inserts for injection molding

This mold is multi-cavities 1*2. The insert positioning block for the copper can be taken out and put in easily from the cavities. The brass insert was preheated to ensure a uniform temperature in the mold cavities.

Basic Information for Connector with Brass

Benefits of Plastic Connector Molded with Brass Insert

Plastic molding part with metal material insert provides you additional functions, you can obtain great advantages including:

It is of electric conduction with brass insert for electronic devices electrical equipment.

To design with screw thread section on the metal, it can be installed to devices and equipment very conveniently.

With metal insert, it enhances the strength of the plastic molding connector.

It is of electrical insulation and heat insulation for safety sake.

With low-level noise.

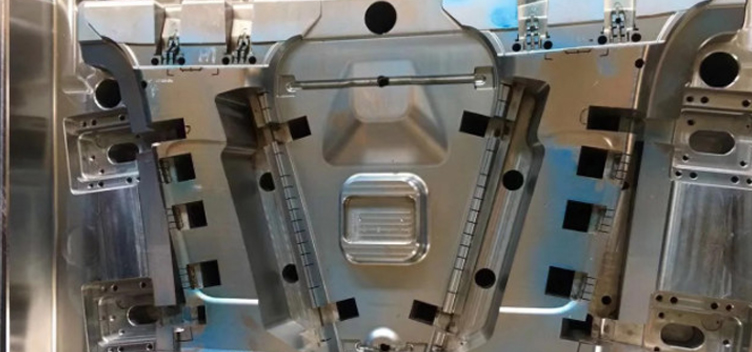

How To Design A Connector With Metal Insert

Select metal materials with a small coefficient of thermal expansion as inlay materials, such as brass, aluminum, aluminum alloy, etc.

The metal design shall not have sharp corners, and shall be properly rounded to improve the plastic strength. The surface of the insert should preferably be provided with exquisite rolling patterns or grooves to increase the friction.

The plastic thickness around the metal insert shall be sufficient. For example, the plastic thickness around the insert is "h", the outer diameter of the metal insert is "D", the plastic thickness for the aluminum insert should be h ≥ 0.8D, and the plastic thickness for the brass insert should be h ≥ 0.9D.

Green Vitality Industry is a professional injection molding factoryin various industries since 1993. We provide metal insert moulding, plastic insert moulding, brass molding inserts, metal insert molding, injection moldand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| Keyboard Mould | Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard mould, ... | |

| LCD TV Mould | TV screen frame mold is used to produce TV screen frames, it should be strong and assembly well with the screen. It has an undercut to lock the scr... | |

| Industrial Plastic Injection Mold | Industrial Plastic Injection Mold The injection molding part is replacing metal products in many fields of industrial applications to meet the... | |

| Auto Bumper Mould | The front and rear bumpers of the car are made of plastic, which not only maintains the protection function, but also has the characteristics of ha... | |

| Injection Mold & Molding Parts Solution | Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |