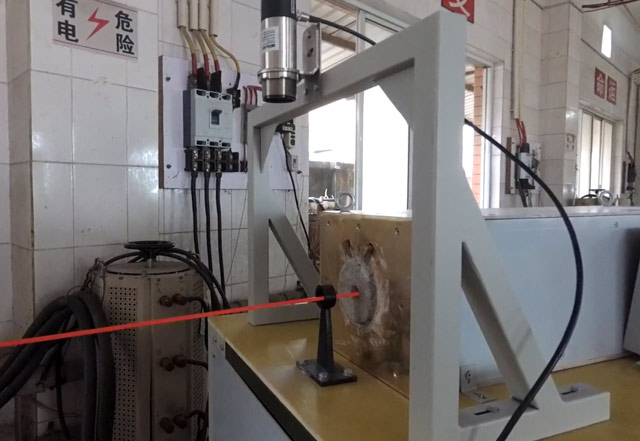

High Frequency Induction Heating Machine

The working frequency of CX series ultra high frequency induction heating machinecovers 50KHZ ~ 120KHZ. You can find the existence of this high frequency heating machineseries in induction welding, tool welding, pipe welding, thermal nesting, thermal packaging, etc.

Types of High Frequency Induction Heating Machine for sale

The high-frequency induction heating equipment is used for various industrial applications such as metal hardening, brazing, welding, forging, and heat treatment. These machines are available in different types and configurations to suit specific heating requirements. Here are some common types of high-frequency heating machine for sale that you can learn detail:

Advantages of JKZ high frequency induction heating machine

Strict selection of high-quality components and optimized design scheme. After long-term use, the induction generator of JKZ high frequency induction heating equipmentcan still work stably and reliably.

A variety of remote control schemes can be selected, and this induction heating equipment can also allow you to control the working status of your high-frequency induction heating equipment through various signals such as on-off signals, 4-20mA, 0-10V, etc.

Equipped with a condition monitoring system (CMS), JKZ high power induction heater can alarm its users about possible equipment failures in real-time

With a lightweight design scheme, it is convenient for customers to flexibly adjust the installation location of our high-frequency inverter for induction heating.

The induction coil of our high-frequency induction heating machine is simple to make and can be adapted to various workpieces of different shapes.

Principle of high frequency induction heatingg

The induction coil of the high-frequency induction heater will generate a powerful magnetic beam of polar instantaneous changes. When operating a high-frequency heater, the metal that requires heat treatment will be placed in the high-frequency coil, and the magnetic beam mentioned above will penetrate the entire ready-to-be-heated metal object. The corresponding powerful high-frequency eddy current heating will then be generated. Since there is a resistor in the metal, strong jeophenia will then be generated and cause the temperature of the inductive heating material to rise rapidly, thereby achieving high-frequency heat treatment.

High Frequency Induction Heating Is Used For?

The main applicable industry range of the high-frequency induction heating machine mainly includes high-frequency wave induction, high-frequency sensing heat treatment, high-tech wave induction metal smelting, etc.

High-frequencyinduction heating generatoris a process that uses an electromagnetic field to generate heat in a metal object. It is used in various industrial applications, including:

Brazing and soldering: Induction heating is used to join two metal parts by melting a solder material between them.

Heat treatment: Induction heating can be used to harden, soften, or temper metals, improving their mechanical properties.

Melting and casting: High-frequency induction furnace can melt and cast metals, such as steel, copper, and aluminum.

Welding: HF induction welding is a non-contact method of joining two metal parts by heating them to a temperature where they fuse together.

Annealing: Induction annealing is a process that heats a metal to a specific temperature and then cools it slowly, making it more ductile and easier to work with.

Surface hardening: high frequency heat treatmentcan be used to selectively harden the surface of a metal object, making it more wear-resistant.

Shrink fitting: High-frequency induction heating can be used to expand a metal object and then quickly cool it, causing it to contract and fit tightly onto another part.

JKZ, as an excellent induction heating manufacturer, offers a wide range of induction heating inverterfor you to choose from.

Send product request

Other supplier products

| Carbide Production | Induction Heating Machines In Carbide Heating with InductionProduction Hard alloy carbide is an important raw material for cutter heads. At presen... | |

| Induction Heating Machines In Wire And Cable | A lot of cables need to be heat-treated before further processing. There is a lot of request about the online induction heating wire with fast spee... | |

| SWS-25A 15-30KHZ 25KW 36A Ultrasonic Frequency Induction Heating Machine | To realize the better performance of SWS-25A, JKZ has designed a fully digital control induction heating generator at the frequency range of 15~30K... | |

| CX2020A 50-120KHZ 20KVA 45A High Frequency Induction Heating Machine | CX2020A high-frequency induction heating converter is designed to work at the frequency range of 50~120KHz and its output power range is 10KW. It i... | |

| Common Quality Problems of Induction Quenching Machine and Ways to Improve Its Working | Performance Ⅰ. Quality problems that often occur in high frequency hardening The application of induction heating equipment in the quenching pr... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |