Industrial Molding Parts

Industrial Molding Parts

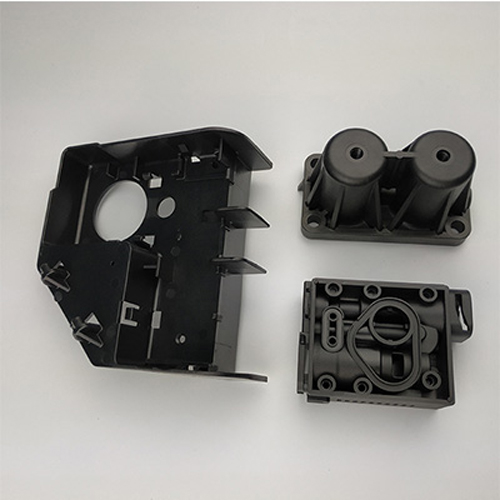

Industrial moulding parts are referred to the plastic parts of industrial precision molded products, we preferred to think of it as non-consumer products.

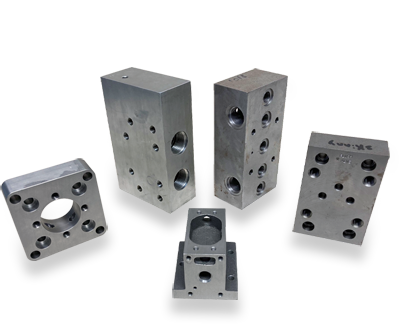

Nowadays, the demand for consumer products is oversupplied, and the demand for industrial products is increasing. This is because many parts of the equipment in the past were made of metal. With the development of the plastics industry, more and more industrial product parts are trying plasticization. Metal parts have higher density, greater strength, and thermal and electrical conductivity. However, plastic industrial parts have advantages in mechanical shock absorption, thermal expansion, elongation at break, and toughness. And the properties of plastics can be greatly transformed by the addition of fillers, reinforcing materials and modified materials, engineering plastics perform better in this respect. Use plastic to produce parts that are not necessary for high strength can reduce the weight of equipment, simplify the structure and save costs, this is why industrial molding parts are becoming more and more common.

Industrial molding parts range from small plastic gears to large industrial equipment plastic enclosures. The design of the mold is very complicated work, the plastic part structure, the different plastic resin, required life cycle, etc. many factors determine the mold construction.

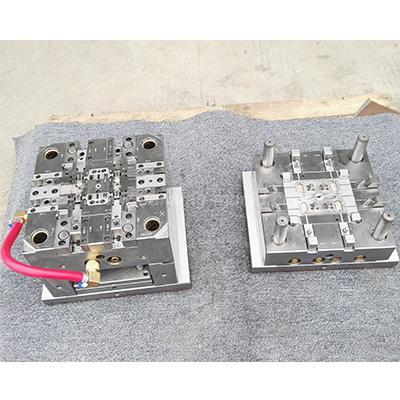

Our designers must master the properties of different plastics and mould steel, and consider the temperature change, pressure change, steel abrasion during the production process, designed qualified industrial moulds.

If the mould structure is unreasonable, even the most excellent operator can not get good plastic parts. The design defects cannot be solved by the defects in the production process. Only when all the factors are considered in the design of the mould, the mould quality and stability of the mass production can be guaranteed.

As a precision molded products inc, we can offer kinds of related products for sale, if you have needs, please contact us.

Hankingtec has become a professional Chinese plastic injection mold supplier china offering custom injection mold design services, plastic moluld project management services, plastic mold manufacturing services, mold trial services, quality control plastic injection moulding services, and semi-finished & finished plastic molds assembly services.

Other supplier products

|

|

Automotive Mold |

Professional Automotive Injection Mold for Cartridge Fuses

TolerancesPlates and Mold Base Components:± 0.013 mm (± 0.0005 in)Cavity c... |

|

|

Multi Cavity Mould |

24 Cavities Plastic Injection Mold

Product Name: 24 Cavities Plastic Injection MoldMold Base: LKM, HASCO, DME, etc.Mold Steel: NAK80, ASSAB8407, S1... |

|

|

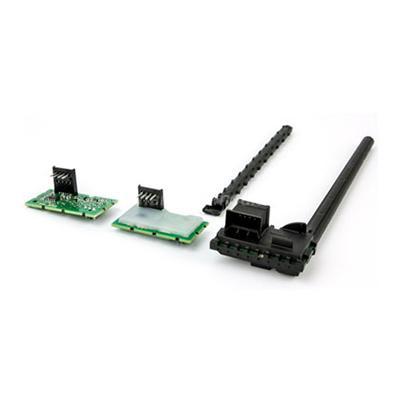

Electronic Molding Parts |

Custom Plastic Molding Product Type: Plastic parts for kids’ electric toothbrush Production Material: ABS No of Cavities: 2 cavities Moul... |

|

|

Plastic Injection Moulding Die Makers |

HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold... |

|

|

Custom Injection Mold Making Services for Auto Parts |

Mould Type: Automotive Final Sensor

Production Material: 33% glass fiber reinforced, black PA 6/12

No of Cavities: 4 cavities

Core Material: S7... |

All supplier products

Same products