Spiral Chute

roduct advantage:

This equipment applies to the size 0.3--0.02 mm fine material such as iron ore, ilmenite, chromite, sulfurous iron ore, zircon, rutile, monazite, xenotime, tungsten ore, tin ore, tantalum ore, Niobium ore, and specific gravity differences of other nonferrous metal and rare metal and non-metallic mineral objects with different proportions.This device has a steady separating process, easy to control, large range of feed ore concentration allows changes, enrichment ratio, high recovery rate, small footprint, less water consumption, simple structure, without power, large capacity, easy to install, easy to operate and quick return from a small investment and so on.

Working principle:

Will spiral chute vertical up, calibration vertical line, with iron frame or wood fixed in suitable of location, by sand pump will ore sent to spiral Shang top two a into material mouth Department, joined supplementary water, regulation mine oar concentration, mine oar natural from high down swirl, in rotating of bevel velocity in the produced a inertia of centrifugal force, to ore of share, and grain degrees, and shape Shang of differences, through swirl of gravity and centrifugal force of role, will mine and sand separate, fine mine inflow fine mine bucket with pipeline received out, tail sand flow into tail sand bucket with pipeline received sand pool, again with sand pump row go, Through the beneficiation process.

Specification:

Model 5LL-1200 5LL-900 5LL-600 5LL-400

Outer diameter (mm) 1200 900 600 400

Pitch (mm) 900/720/540 675/540/405 450/360/270 240/180

Apart diameter to compare(p/d) 0.72/0.6/0.45 0.75/0.6/0.45 0.75/0.6/0.45 0.6/0.45

Crosswise inclination angle(°) 9° 9° 9° 9°

Each most installment spiral number 4 4 3 2

Ore granularity(mm) 0.3-0.03 0.3-0.03 0.2-0.02 0.2-0.02

Ore density (mm) 25-55 25-55 25-55 25-55

Capacity (t/h) 4-6 2-3 0.8-1.2 0.15-0.2

Outlook size Length(mm) 1360 1060 700 460

Width (mm) 1360 1060 700 460

Height (mm) 5230 4000 2600 1500

weight(kg) 600 400 150 50

Other supplier products

|

|

Ball Mill Series |

Application: It will be widely used in cement, Silicate Products new building material, refractory material, fertilizer, black and nonferrous met... |

|

|

Rotary Dryer Series |

Technical Advantage:

Equipped with Spreading plate, cylinder support the two roller by tyre, the gear wheel used to prevent the cylinder axial mo... |

|

|

Magnetic Separator Series |

Application fields:Mineral processing

Materials:Suitable for wet magnetic separation of pyrrhotite, roasting ore, ilmenite, and other materials ... |

|

|

Compound Cone Crusher |

Application fields:Widely used in mining ore crushing, broken broken rocks with high hardness materials, building materials, cement, aggregates,... |

|

|

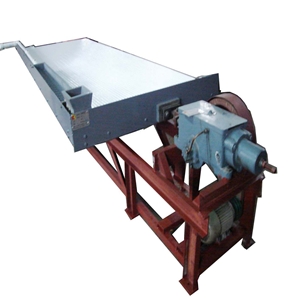

Shaker |

Application fields:Mineral processing

Materials:It is widely used in the tin,wolfram,gold,and silver, lead, zinc, tungsten, tantalum, niobium,ti... |

All supplier products

Same products