Principle Analysis of Over Moulding Technology for Injection Mold

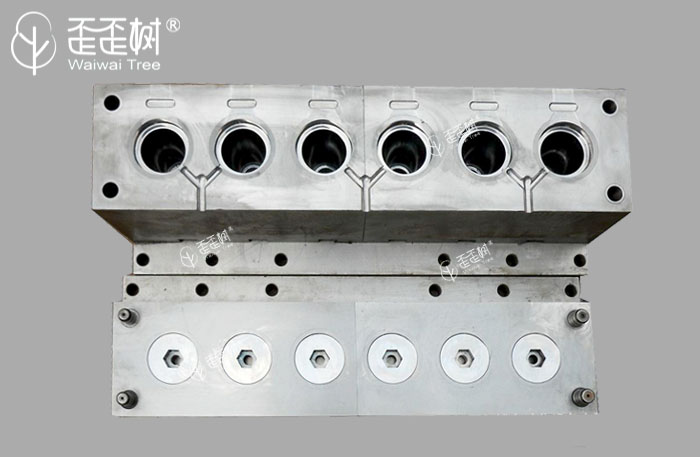

In the past 10 years, over-mouldingtechnology has completely changed the aesthetic standards, design ideas and functional requirements of consumer goods. Medical device manufacturers also recognize the potential advantages of the technology and continue to expand its application in the medical field. Secondary injection moulding technology is famous for creating "soft surface". But it also has many other functions, such as ergonomic design, two-color appearance, brand identification and feature improvement. Using this technology, we can increase the functions of products (such as noise reduction, shock absorption, waterproofing, collision avoidance) and added value. Secondary injection, like co-injection, double injection and sandwich injection, belongs to multi-material injection technology. The basic idea of multi-material injection moulding is to combine two or more materials with different characteristics to improve product value. In this paper, the first kind of injection material is called base material or base material, and the second kind of injection material is called cover material.

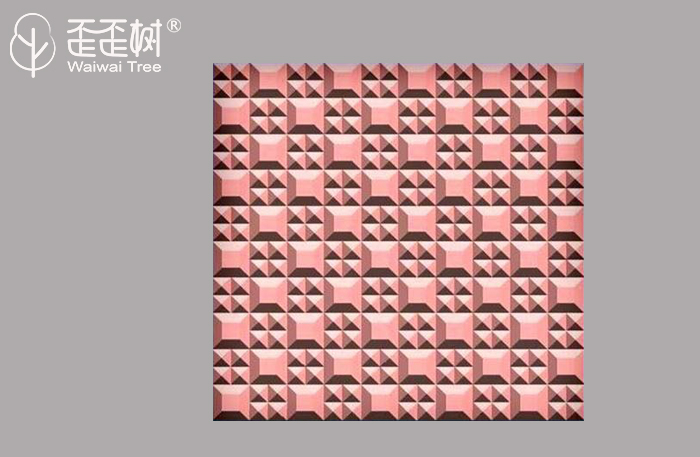

In the Over Mouldingprocess, the covering material is injected into the upper, lower, surrounding or inner parts of the substrate to form a complete component. This process can be accomplished by multiple injection moulding or embedded injection moulding. The commonly used covering material is elastic resin.

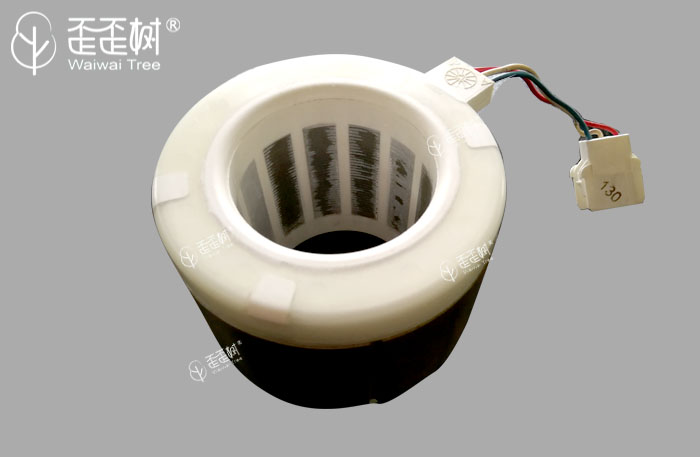

The high-composite precision molds produced by Waiwai Tree have the characteristics of low energy consumption; our SMC and BMCcompoundmolds have no waste, and there is no need to clear the inner cavity. Having only a small temperature difference, our SMC/BMC composites have stable mold temperature, good appearance, and high efficiency. Thus, they are now widely used in new energy vehicles, high-speed rail, and electric motors.

Send product request

Other supplier products

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| What is a BMC Mould? What Are the Features and Applications? | BMC is the abbreviation of Bulk Molding Compounds. It is also cluster moulding plastics. What is a BMCmould? What are the features and applicati... | |

| Insulation Mold | Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner and the parting surface. Sinc... | |

| Principle Analysis of Over Moulding Technology for Injection Mold | In the past 10 years, over-mouldingtechnology has completely changed the aesthetic standards, design ideas and functional requirements of consumer ... | |

| BMC/SMC Motor | BMC/SMC ElectricMotorsDescription BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has high... |

Same products

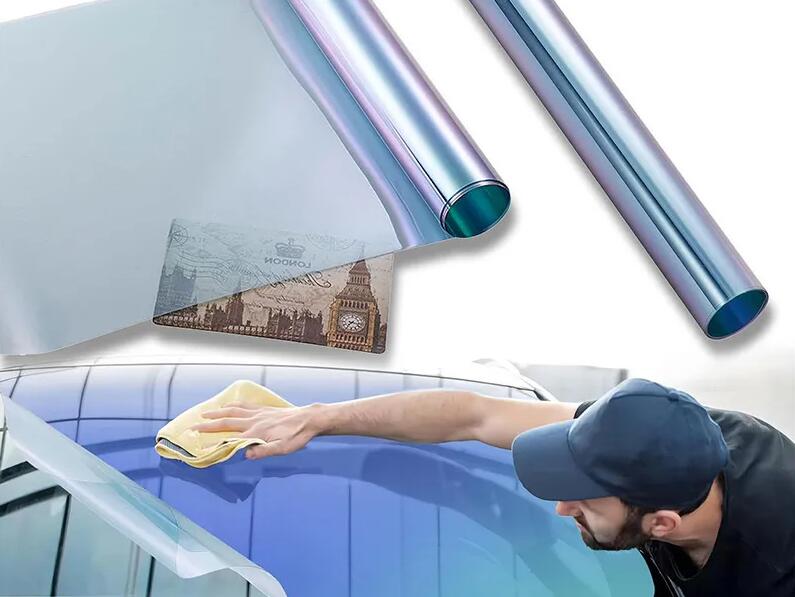

| Windshield Film | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Windshield Film The automotive windshield film is installed on the outside of the windshield and ... | |

| Metallized Window Tint | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Metallized Window Tint The multi-layer magnetron sputtering double silver series has the charact... | |

| Matte PPF | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Matte PPF Mattepaint protection filmhas the beauty of a matte finish and a better natural light.... | |

| Textured Film | Seller: Beijing Kingfilm Advanced Material Co., Ltd | Textured Film The TexturePaint Protection Filmsnot only has the texture of carbon fibre, but als... | |

| Customizable Electric Tonneau Cover | Seller: Guangzhou Zhenlonghui Auto Accessories Co., Ltd. | Customizable Electric Tonneau Cover The advanced all-electric retractable Tonneau cover gives yo... |