METAL STAMPING

Stamping is a cold stamping process, which is to cut, bend or shape the material into the finished shape and size in accordance with the mold with the punching force from the stamping machine. As one of the leading China stamping metalworking manufacturers, Hunkmachining provides varied high-quality metal stamping solutions for customers worldwide. Our custom metal stamping services include metal punching, metal blanking, metal bending, metal flanging, metal deep drawing and metal hemming. Feel free to contact us for your own custom metal stamping price!

CUSTOM METAL STAMPING SERVICES BENEFITS

01

Accuracy

Precision is a significant factor especially in industry manufacturing. Any inaccuracy may inflict serious losses and damages. With the advanced metal stamping technology and die design, errors can be minimized in the production.

02

Cost-efficiency

Custom metal stamping can reduce remarkable production time as well as the labor required. Based on that, companies can save plenty of cost by reducing the number of workers and running time of machines. As a result, customers can benefit a lower cost from those savings that reflect the product price.

03

High quality

In addition to the advantages mentioned above, quality is also a major factor in the reason why choosing custom metal stamping services. Through a long time of development, stamping parts have been proven to be so reliable that they are frequently used in many high-precision industries including aerospace and medical device.

METAL STAMPING MATERIALS

Carbon Steel

The versatility of carbon steel is outstanding because of its high ductility. It can be formed into various shapes by metal stamping. Carbon steel metal stamping is commonly used in the automotive industry.

Stainless Steel

Stainless steel has good resistance to corrosion and great durability, which makes it suitable for custom metal stamping services. Stainless metal stamping is frequently used in medical industry and kitchenware as it is antibacterial(compounded with special elements) and easy to clean.

Aluminum

The density of aluminum is quite low comparing to its strength(high strength-to-weight ratio) and that makes it a good choice for metal stamping. Same as stainless steel, aluminum also has high corrosion resistance. Besides, it is a cost-effective material. Usually, aluminum metal stamping is applied for vehicles and agriculture machines.

Other Metal Materials

Brass, copper, ferroalloy and some other alloys are also workable for custom metal stamping in some industries.

CHINA METAL STAMPING CAPABILITIES

With over 8000 square feet of physical plant, Hunkmachining has ample space to accommodate our operations efficiently. Our facility is equipped with state-of-the-art equipment, including high-capacity presses, with the highest tonnage reaching 300 tons. This enables us to handle a wide range of stamping projects, from small-scale to large-scale production.

One of our key strengths lies in our ability to offer custom metal stamping services through our in-house tooling and mold development capabilities. Our team of experts can design and develop molds tailored to the specific requirements of our clients, ensuring precision and accuracy in the sheet metal stamping process. This capability allows us to provide specialized and customized stamping solutions.

With over 20 punch presses in our inventory, we have a diverse range of tonnage capacities available, complemented by hydraulic and oil presses. This ensures that we can handle a variety of stamping projects with different specifications and complexities. Additionally, our presses offer stroke ranges of up to 12", allowing for flexibility in producing parts of varying depths.

As one of the leading stamping metalworking suppliers in china, Hunkmachining prioritizes streamlined workflows to optimize productivity and maintain high-quality standards. For customers interested in observing our operations, we are more than happy to provide them with a glimpse of our stamping equipment, showcasing our commitment to cutting-edge technology and advanced manufacturing processes.

Overall, Hunkmachining combines advanced machinery, custom mold development capabilities, and a spacious facility to deliver efficient, high-quality, and cost-effective oem metal stamping solutions for high-volume metal stamping needs.

METAL STAMPING APPLICATIONS

Metal stamping is a widely used manufacturing process that involves forming and shaping metal sheets or coils using stamping dies. Metalwork stamping services find applications in various industries, delivering cost-effective solutions for producing complex parts in high volumes.

Automotive

Metal stamping plays a crucial role in the automotive industry for manufacturing components such as body panels, brackets, chassis parts, and engine components. The process enables the production of precise and durable parts that meet the stringent quality and safety standards of the automotive sector. High-quality metal stamping also supports mass production, making it a cost-effective solution for the high-volume manufacturing needs of the automotive industry.

Agriculture

Metal stamping in the agricultural industry is utilized for manufacturing components for equipment, irrigation systems, grain storage, livestock equipment, and animal housing. It ensures the production of durable and precise parts that contribute to efficient and reliable agricultural operations. OEM metal stamping plays a crucial role in supporting the growth and productivity of the agricultural sector.

Electronics

Metal stamping is extensively used in the electronics industry for producing components such as connectors, terminals, brackets, and heat sinks. The process enables the precise formation of complex shapes required for electronic devices and systems. Metal stamping provides cost-effective solutions for producing high-volume electronic components while maintaining tight tolerances and ensuring consistent quality.

Aerospace Industry

In the aerospace sector, OEM metal stamping is utilized for producing intricate and lightweight components. It is employed in the manufacturing of aircraft structural parts, including wing ribs, brackets, and engine mounts. Metal stamping ensures the production of parts that meet the strict weight, strength, and dimensional requirements of the aerospace industry, contributing to improved fuel efficiency and enhanced performance of aircraft.

Medical

Metal stamping is vital in the medical industry for manufacturing various medical devices and equipment. It is utilized in the production of surgical instruments, implantable devices, diagnostic equipment, and medical device components. Cusotm metal stamping allows for the production of intricate and precise components that meet the stringent regulatory requirements of the medical industry, ensuring the highest standards of quality and reliability.

Consumer Goods

The consumer goods industry relies on metal stamping for producing a wide range of products, including household appliances, kitchenware, hardware, and decorative items. Metal stamping enables the cost-effective mass production of complex and customized designs, meeting the demands of consumers for aesthetically appealing and functional products.

METAL STAMPING PROCESS

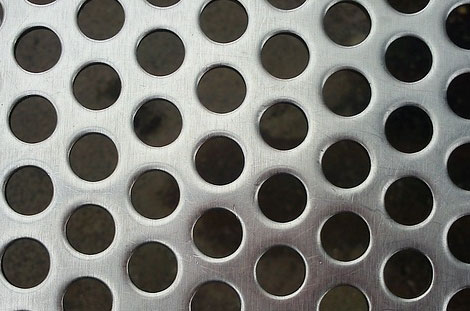

Metal stamping is a versatile manufacturing process used to shape coils or flat sheets of material into specific forms. It encompasses various techniques like blanking, punching, embossing, and progressive die stamping. These techniques can be combined or used independently depending on the complexity of the part. Metal stamping involves feeding the material into a stamping press where tools and dies shape the metal. This process is ideal for mass-producing complex parts, from car door panels to small electrical components for electronics.

As a pro stamping metalworking supplier, Hunkmachining specializes in custom metal stamping using materials such as copper, brass, stainless steel, and steel alloys. We offer competitive lead times and can produce over one million stamping parts. Our capabilities include producing small, medium, and large parts with press bed lengths up to 10 feet and widths up to 20 feet. We can work with metal thicknesses ranging from .025 to .188 inches, and even thicker depending on the material and forming technique.

To ensure we meet your unique requirements, our project managers and experts personally review and provide manual quotes for each metal stamping project. We strive to deliver a fast and seamless manufacturing experience. Discover more about the metal stamping process and our capabilities by exploring the sections below.

If you need any kinds of all metal welding, please contact us, as a professional metal processing factory, Hongkun is willing to offer you high quality products.

Send product request

Other supplier products

| METAL STAMPING | Stamping is a cold stamping process, which is to cut, bend or shape the material into the finished shape and size in accordance with the mold with ... | |

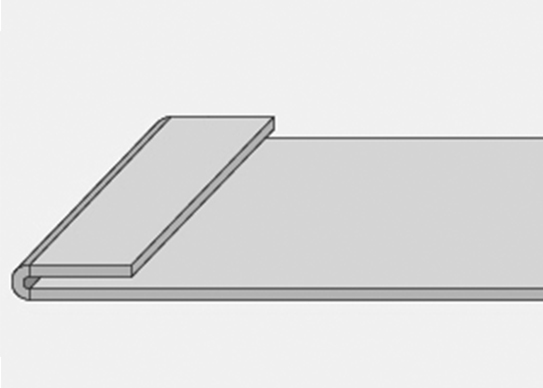

| METAL HEMMING | Metal hemming is a process that involves folding the edge of the sheet metal to 180° onto itself. Then, two newly formed layers are flush with ... | |

| METAL WELDING | Metal Welding Service Welding is a manufacturing process and technology to join metals or other thermoplastic materials such as plastics by heat... | |

| METALWORKING SERVICES & PRODUCTS IN AGRICULTURAL | Agriculture is closely related to metalworking processes. Modern agriculture is extremely efficient, largely thanks to a well-developed metal proc... | |

| METAL WELDING | Metal weldingis a manufacturing process and technology to join metals or other thermoplastic materials such as plastics by heating, high temperatur... |

Same products

| BLIIOT BL360 Industrial ARM Computers Powered By NXP Mx8m Mini with Quad Core Cortex A53 M4 | Seller: Shenzhen Beilai Technology Co., Ltd. | BL360 Industrial ARM Computers built on NXP i.MX8M Mini with quad-core Cortex-A53+M4. As a Indust... | |

| BLIIOT ARMxy BL350 Industrial Embedded Computer With Ti Sitara Am62x Processor | Seller: Shenzhen Beilai Technology Co., Ltd. | BL350 is an Industrial Embedded Controller powered by the TI Sitara AM62x processor with up to qu... | |

| BLIIOT BL460 Powered by Raspberry Pi CM5 Industrial Embedded Computer | Seller: Shenzhen Beilai Technology Co., Ltd. | Industrial AI Embedded Computer BL460 based on the Raspberry Pi CM5 module and compatible with th... | |

| 30-160KW 10-30Khz Induction Heating Machine | Seller: Chengdu Duolin Electric Co.,Ltd | 30-160KW 10-30Khz Induction Heating Machine Ultrasonic induction heating equipment IGBT inverte... | |

| Vertical Bendable Neon Flex LED Strips 15X16mm | Seller: Shenzhen Blue Diamond Technology Co.,Ltd | Vertical Bendable Neon Flex LED Strips 15X16mm This Vertical Bendable Neon Flex LED Strips are v... |