METAL HEMMING

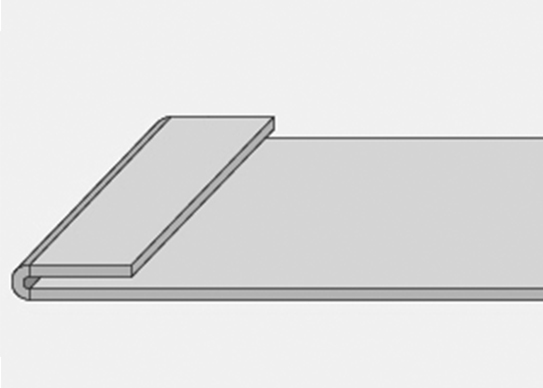

Metal hemming is a process that involves folding the edge of the sheet metal to 180° onto itself. Then, two newly formed layers are flush with each other. Many automotive parts are produced by metal hemming, such as trunk lids, deck lids, hoods, tailgates and doors. There are 4 types of metal hemming: teardrop hem, closed hem, open hem and rolled hem. The closed hem is the most popular one as the process is simple. It is totally flush. However, it has material limitations, including thickness and angle limitations to avoid fracture.

WHAT IS THE PURPOSE OF METAL HEMMING?

Generally, metal forming is used to connect parts together to achieve a better appearance and strengthen the edges of parts.

HOW TO HEM MATERIAL WITH LOW FLEXIBILITY?

For some material such as aluminum, the closed hem is not an ideal choice, since the flexibility them are not enough and they are easy to break during the process. Instead, teardrop hem is the best choice for this material. It is a flange which is bent over more than 180° with only marginal inside radius change, and that is the reason why it can process that low-ductility without fracture.

WHAT IS THE DIFFERENCE BETWEEN METAL HEMMING AND METAL SEAMING?

Hemming and seaming are two very similar metalworking processing that both involve bending metal over onto itself. The difference is that seaming is to use a seam to join two layers of metal sheet together and two layers are not flush with each other while on the other hand two layers are flush with each other with hemming.

If you need any kinds of metal work fabrication, please contact us, as a professional fabrication work company, Hongkun is willing to offer you high quality products.

Send product request

Other supplier products

| METAL STAMPING | Stamping is a cold stamping process, which is to cut, bend or shape the material into the finished shape and size in accordance with the mold with ... | |

| METALWORKING SERVICES & PRODUCTS IN AGRICULTURAL | Agriculture is closely related to metalworking processes. Modern agriculture is extremely efficient, largely thanks to a well-developed metal pr... | |

| MOWER PARTS | Hunkmaching has been manufacturing oem mower parts used on many top brands including Bad Boy Mowers and John Deere. We offer good quality parts ran... | |

| CAR SEAT BRACKET | The main function of custom car seat bracketsis to keep the driver in a correct sitting position, provide support for the upper body when turning, ... | |

| METAL DEEP DRAWING | Metal deep drawing chinarefers to a kind of machining process in which a certain shape of flat blank obtained after blanking is stamped into variou... |

Same products

| Radio frequency signal generator | Seller: Shijiazhuang Suin Instruments Co., Ltd | Radio frequency signal generator Radio frequency signal generator Overview Adopting DD... | |

| Commercial Vehicle Brake Pad WVA 29173 | Seller: Qingdao Allmax Auto Parts Co., Ltd | ● ECE-R90 Certificate approved ● With warranty of 100000km-200000km ● OE supplier for 20 years ... | |

| Commercial Vehicle Brake Pad WVA 29125 | Seller: Qingdao Allmax Auto Parts Co., Ltd | ● ECE-R90 Certificate approved ● With warranty of 100000km-200000km ● OE supplier for 20 years ... | |

| Custom Vehicle Brake Disc 9424212112 | Seller: Qingdao Allmax Auto Parts Co., Ltd | Product Description Your is the silver piece that your brake pads push to bring the vehicle to... | |

| Commercial Vehicle Brake Disc 140272 | Seller: Qingdao Allmax Auto Parts Co., Ltd | Product Description ECE-R90 Certificate approved With warranty of 1 year OE supplier No bub... |