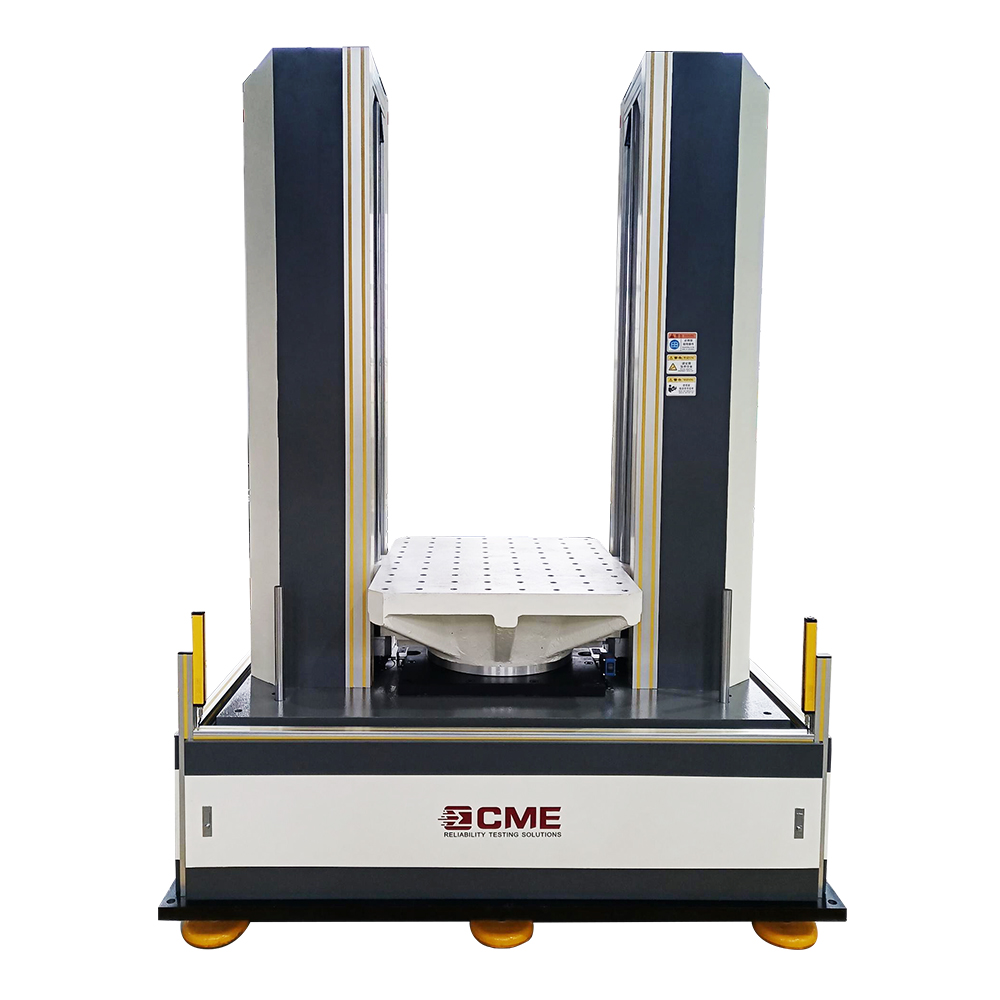

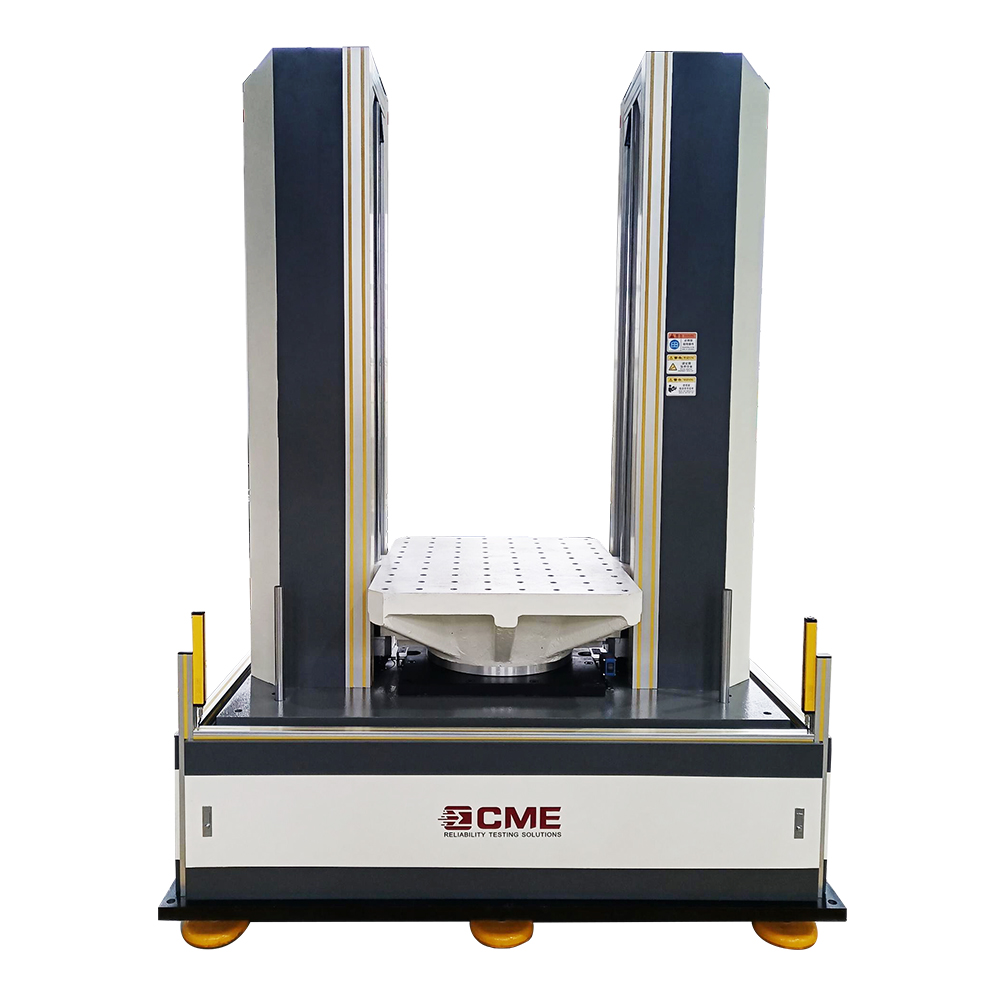

KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE

KRD11 is a fully automatic pneumatic lifting vertical shock test machine. It is vertical shock test equipment with a novel design, high degree of automation, simple operation, and convenient maintenance. It is used to measure and determine the impact resistance of products or packaging and assess the functional reliability and structural integrity of the test product in a shock environment. KRD11 series pneumatic shock test system meets the requirements of both shock and bumps test, shock testing waveform including conventional half-sine wave, post-peak sawtooth wave, trapezoid wave, to realize the shock wave and shock energy that the product is subjected to in the actual environment, thereby improving the system or optimizing the structure of the product. This equipment meets standards of IEC68-2-27, MIL-STD-202, MIL-STD-750, MIL-STD-810, MIL-STD-883, etc.

FEATURES OF KRD11 VERTICAL pneumatic shock test machine

Pneumatic drive, simple structure and high reliability, without hydraulic leak risk.

Pollution free, without hydraulic leak risk and keep the environment clean.

Pneumatic drive greatly improves the shock test efficiency, maximum shock rate up to 120 times / min.

Impact testing for small pulse lower to 0.3ms.

Shock testing machine with high acceleration is up to 3000g.

It can easily realize large shock pulse width and small overload test.

With a fast shock rate comparing to motor or hydraulic driven collision-bump table, it has higher reliability and better collision-bump waveform.

The speed and rate of shock can be easily controlled by adjusting the gas pressure.

IPS-2000 shock control and measurement system can perform manual shock, continuous shock (bump test), single shock, and interval shock.

Built-in brake mechanism ensures the safety of operation in any situation.

TECHNICAL SPECIFICATIONS OF KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE

Buy reliability test equipment.

TABLE OF KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE

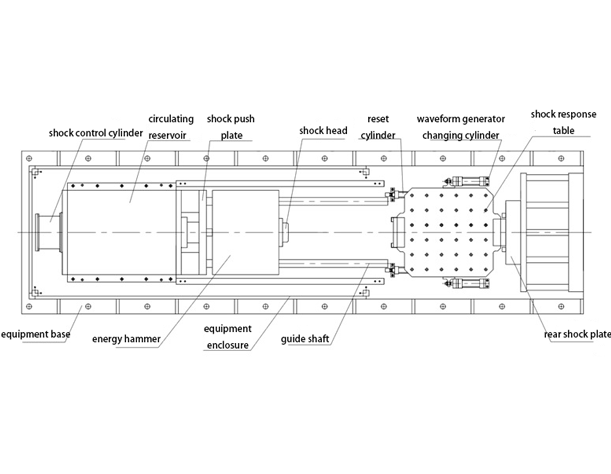

The test sample is installed on the worktable, which is guided by two high-precision sliding guides and can move up and down. The two cylinders are connected to the worktable by sliding guides. When the cylinders are inflated, the piston rod rises to drive the worktable to lift. The workbench is lifted. When it is raised to the set height, the cylinder quickly deflates, and the bottom surface of the worktable hits the waveform generator to complete a shock process.

By adjusting the rising height of the worktable, different initial shock speeds can be obtained, and thus different shock overload values can be obtained; while changing the stiffness of the waveform generator, different pulse width values can be obtained. The structure schematic diagram is shown in following figure:

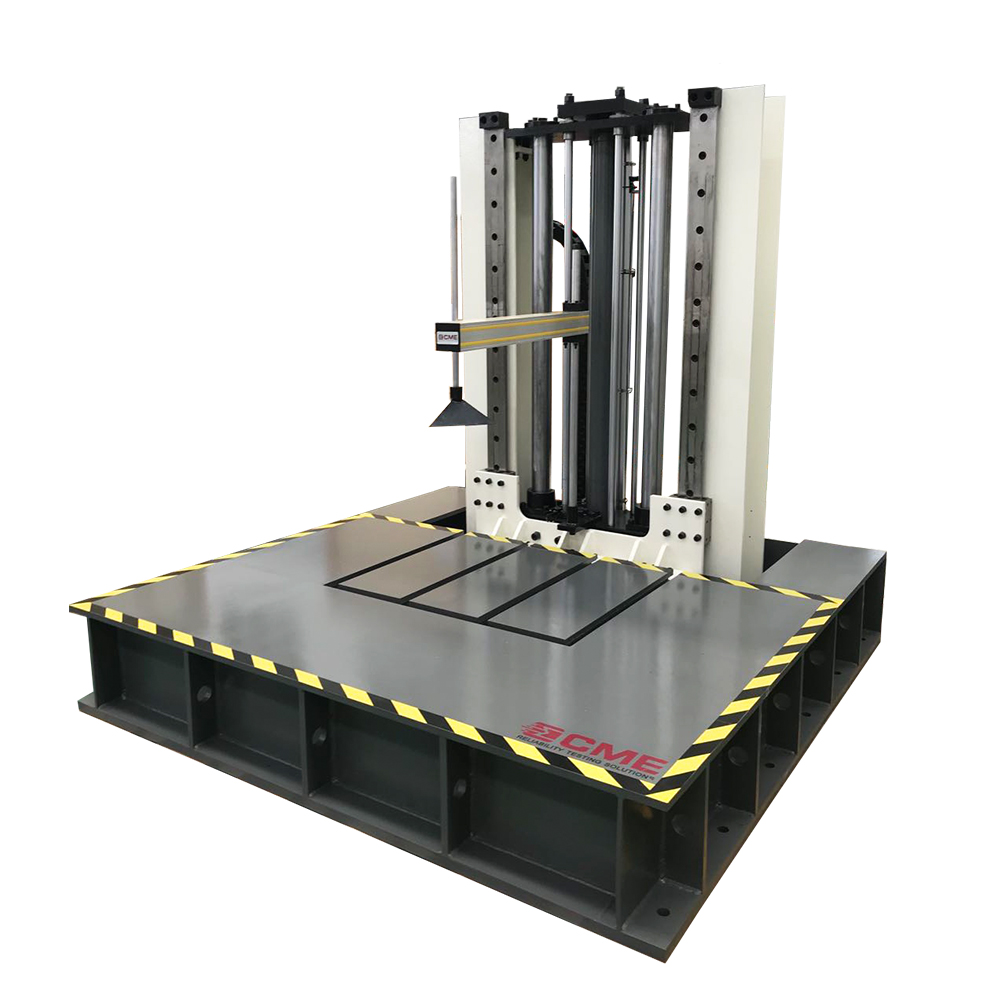

DUAL MASS SHOCK AMPLIFIER OF KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE

The shock amplifier is a device that uses the rebound energy of the ordinary shock table to realize the opposite impact between the servo table and the seat on the amplifier so that the impact acceleration is multiplied.

DUAL MASS SHOCK AMPLIFIER OF KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE

WAVEFORM GENERATORS FOR KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE

KRD11 pneumatic shock test system is equipped with a half-sine wave generator. The half-sine wave generator is mainly made of engineering rubber (considering the stiffness and cohesive force of rubber) and felt pads of various thicknesses. Different thicknesses are connected in series to form multiple stiffnesses to achieve different shock pulse widths.

Optional for post-peak sawtooth wave generator which is lead cone; trapezoidal wave generator air source is high-pressure nitrogen, the pressure range is 1-10MPa, and the overload value can be adjusted between 10-100g, as shown in the following figure:

Send product request

Other supplier products

| KRD40 ZERO DISTANCE DROP TEST MACHINE | KRD40 series zero-distance drop shock test machineis a single lifting servo motor driving drop shock machine, which is mainly used for packaging go... | |

| KRD11 Pneumatic Vertical Shock Test Machine | KRD11 is a fully automatic pneumatic lifting vertical shock test machine. It is vertical shock test equipment mechanicalwith a novel design, high d... | |

| KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE | KRD11 is a fully automatic pneumatic lifting vertical shock test machine. It is vertical shock test equipment with a novel design, high degree of a... | |

| KRD50 TRANSPORTATION SIMULATION VIBRATION TESTING MACHINE | KRD50 transportation vibration testercan replace the actual running automotive test to complete the road transportation simulation test of packaged... | |

| KRD15 Pneumatic Horizontal Shock Response Spectrum Test System | KRD15 pneumatic horizontal shock response spectrumtester is the special equipment for spectrum specification shock test, so it can also be called s... |

Same products

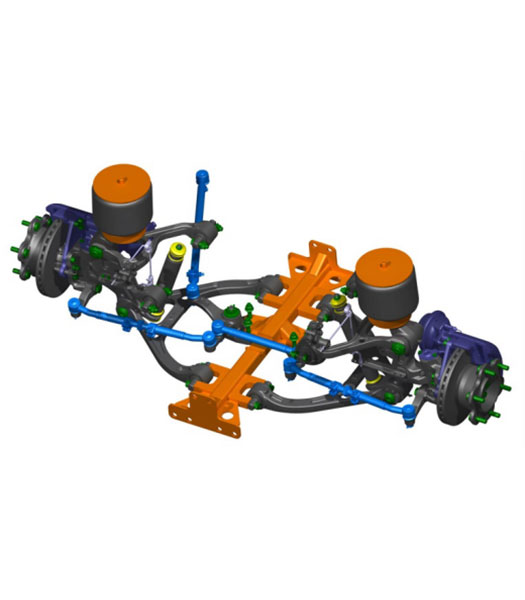

| Independent Air Suspension | Seller: Shanghai Komman vehicle component systems stock co., ltd | Air suspension systemis generally divided into independent air suspension and nomal air suspensio... | |

| D11 Motor Mount For Bosch Ebike Motor | Seller: Shanghai Komman vehicle component systems stock co., ltd | Port: Shanghai, China Production Capacity: 20000T/Year Paymen... | |

| Bus Air Suspension | Seller: Shanghai Komman vehicle component systems stock co., ltd | What is air suspension bus Bus air ride suspensionis also called air bag suspension,the differen... | |

| 6-8m Bus Front Air Suspension System | Seller: Shanghai Komman vehicle component systems stock co., ltd | 6-8m Bus Front Air SuspensionSystem Port: Shanghai, China Production Cap... | |

| 50 Cylinder Diameter Shock Absorber | Seller: Shanghai Komman vehicle component systems stock co., ltd | Item name: Shock absorber Port: Shanghai, China Production Ca... |