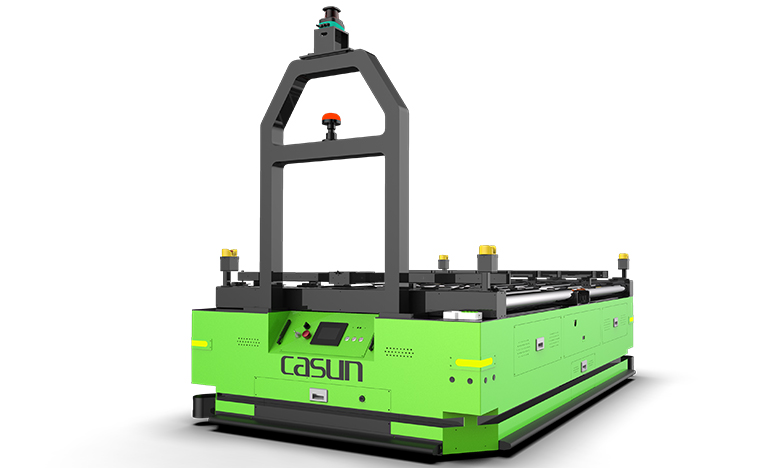

C2-33 Omni-directional Latent Lifting AGV

C2-33 Omni-directional Latent Lifting AGV can move to the bottom of the material trolley, lift the material trolley and move to the destination. In addition, the lifting AGV also has the functions of in-situ rotation and side shift, the maximum load capacity can reach 3000KG, and the moving speed can reach 45m/min when fully loaded. You can choose to use QR code navigation or magnetic stripe navigation according to the actual situation of the site.

Parameters of C2-33 Omnidirectional Latent Lift AGV

|

Navigation |

Magnetic /QR code robot navigation/ SLAM |

Stopping accuracy |

±10mm |

|

Vehicle dimensions |

L2250*W1100*H400(mm) |

Driving mode |

Steering-wheel drive |

|

Moving direction |

Move forward/backward/sideways, rotate |

Charging mode |

Side/Ground charging |

|

Load capacity |

2500KG / 3000KG |

Battery |

Lithium battery |

|

Rated speed |

0~45m/min |

Communication |

WiFi/5G |

|

Lift height |

50mm |

Safety warning |

Light + Audio |

|

Turning radius |

1200mm (magnetic) |

Safety sensing range |

≤3m(adjustable) |

|

Guidance accuracy |

±10mm |

Safety protection |

Front obstacle detecting sensor+Mechanical anti-collision bumper +Emergency-stop switch |

Core Advantages of C2-33 Omnidirectional Latent Lift AGV

01

Strong carrying capacity

The carrying capacity can reach 3000KG, and the full load moving speed can reach 45m/min.

02

Strong adaptability to the environment

The map is self-learning, and the operation map is automatically updated according to the on-site environment when working, which greatly improves the environmental adaptability.

03

Lifting control

It can interact with the elevator to complete the operation of automatically going up and down floors.

04

High positioning accuracy

The primary positioning accuracy can reach ±10mm, and the secondary positioning accuracy can reach ±5mm

05

High work efficiency

Equipped with a full servo drive, it can increase the speed quickly (0-72 meters per minute only takes 3 seconds), and has a fast rotation function (only 3 seconds for in-situ rotation)

06

Multi-AGV linkage

Synchronous linkage of multiple AGVs is suitable for complex material handling scenarios.

07

Automation and labor saving

No manual intervention is required in the production process, and the scheduling system is fully automatic.

08

Fault self-check

With fault self-checking function, remote fault diagnosis and self-recovery function.

09

Automatic battery charging

When the AGV detects a low battery state, it will automatically move to the charging station for charging. The online time can reach 24 hours a day to improve productivity.

10

Multiple security protection

Equipped with laser obstacle detection sensor, mechanical anti-collision device and sound and light warning to ensure safe operation

As one of the most professional agv manufacturers, we provide amr automated mobile robot, avg robot, automated guided vehicle for sale, etc. For agv robot price or more information, please feel free to contact us!

Send product request

Other supplier products

| C4-C1 Rear Traction AGV | C4-C1 traction AGV is a laser guide navigation traction tugger AGV, using the tail traction device to pull materials, the traction capacity can rea... | |

| CCM-11 Customization AGV | CCM-11 Customization AGV CCM-11 customized agv laseris customized for SMT production line, supporting customized navigation mode according to dema... | |

| Latent Lifting AGV | Automated guided AGV lift carts could realize accurate self-positioning according to dispatched tasks and lift, transport as well as unload automat... | |

| C3 Unit Load Carrier AGV Trolley | Load shifting series AGV trolleycan autonomously navigate to the docking terminal according to the scheduling task, realizing the fully automated t... | |

| C2-23 Bidirectional Latent Lifting AGV | C2-23 Bidirectional Latent Lifting agv amrruns to the bottom of the material trolley, lifts the material trolley and transports it to the destinati... |

Same products

| SK222 Non Sparking Phillips Screwdriver | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | SK222 Non Sparking Phillips Screwdriver Our non-sparking Phillips screwdriveris made from beryll... | |

| K238B Non-sparking Sledge Hammer | Seller: Hebei Sikai Safety Tools Manufacturing Co.,Ltd | K238B Non-sparking Sledge Hammer Non sparking sledge hammer is one kind of heavy-duty non sparki... | |

| PV Cleaning Vehicle | Seller: Trinabot Co., Ltd | The PV cleaning vehicleutilizes a cutting-edge leapfrog design structure, incorporating four-whee... | |

| YCX M9 Professional Screen Tester for True Tone and Refresh Rate Testing | Seller: Phonefix | YCX M9 Intelligent Screen Tester works with iPhone 6-16 Pro Max, Samsung, Huawei, Xiaomi, OPPO, V... | |

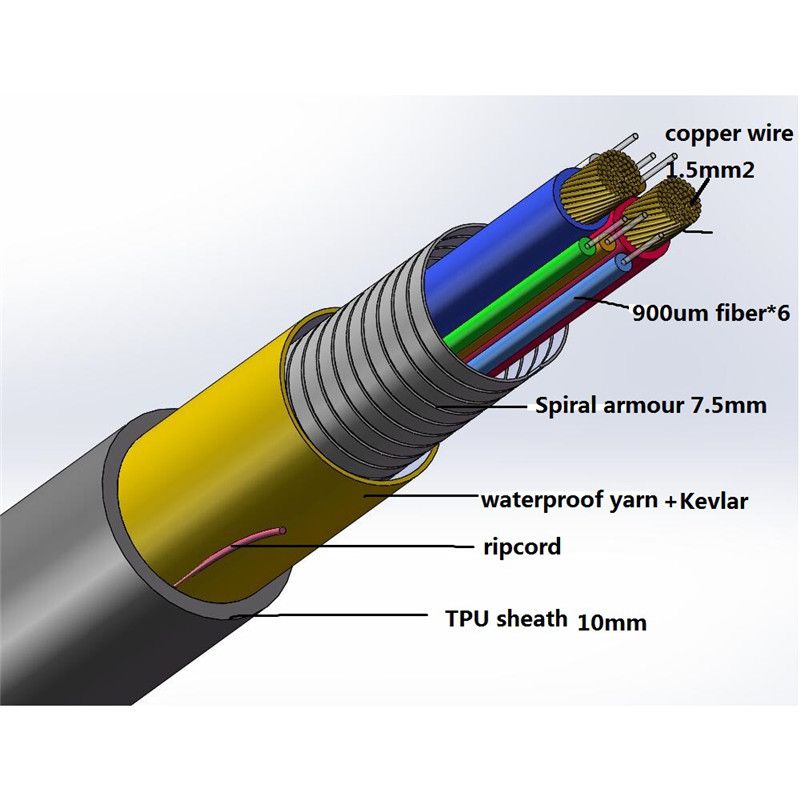

| copper fiber composite cable | Seller: Shenzhen Wirenet Telecom Technology Co., Ltd. | copper fiber composite cable Copper Fiber Composite Cable are hybrid cables that combine op... |