Home

Stamping mold is a special process equipment for processing materials (metal or non-metal) into parts in cold stamping processing, called cold stamping die. Stamping is a pressure processing method that uses a mold installed on a press to apply pressure to the material at room temperature to cause separation or plastic deformation to obtain the required parts.

Stamping Mold Products by COSMOPlat

Did not find what you were looking for~

Maintenance Methods of Stamping Mold

There are several conditions that may occur in the process of stamping mold. And maintenance methods are under below:

(1) Loose die: The movement of punch or die exceeds the single side clearance. Adjust the combination clearance.

(2) Punching die tilt: The straightness of punching or die is not correct, or there is a foreign object between the templates, so that the templates cannot be attached flat. Reassemble or grind to correct.

(3) Template deformation: Template hardness or thickness is not enough, or deformation by external impact. Replace the new template or correct the demolition group work method.

(4) mold base deformation: mold base thickness is not enough or uneven force, guide column, guide bush straightness variation. Grinding correction or re-fill plastic steel or replace the mold seat or make the force average.

(5) Die interference: die size, position is correct, the upper and lower die positioning deviation, whether the group will be loose, the precision of the punching machine is not ì, the frame die is not correct.

(6) Punching and shearing skew: the punch is not strong enough, the size of the punch is too close, the lateral force is not balanced, and the punch is half skewed. Strengthen the role of peeling slant plate guide protection or punch increase, small punch grinding short lt increase heel heel long early support guide, pay attention to the feeding length.

Common Material for Stamping Mold

The most common materials used in stamping mold production are metal materials (including ferrous and non-ferrous metals), but sometimes non-metal materials are also used. Among the ferrous metals are mainly ordinary carbon structural steel, high-quality carbon structural steel, alloy structural steel, carbon tool steel, stainless steel, electrical silicon steel, etc.; non-ferrous metals are mainly pure copper, brass, bronze, aluminum, etc.; non-metallic materials are cardboard, laminate, rubber plate, plastic plate, fiber plate and mica, etc.

The supply state of metal materials for stamping is generally various specifications of sheet and strip. The sheet material can be used for the production of engineering dies, and the strip material (coil material) is used for the production of continuous dies. The plate material is larger in size and can be used for stamping of large parts, or the plate material can be cut into strips for stamping of small and medium-sized parts according to the size of the layout; the strip material (also called coil material) is available in various specifications of width, and the unrolled length can reach several tens of meters, and is supplied in rolls, which is suitable for automatic feeding in mass production of continuous dies.

For the grades, specifications and properties of various materials, please refer to the relevant manuals and standards.

Advantages of Stamping Manufacturing

Compared with other method of machining and plastic processing, stamping manufacturing has many unique advantages in terms of technology and economy industry. The main excellent performance is as follows.

(1) The production efficiency of stamping manufacturing is high, and the operation is convenient and easy to realize mechanization and automation. This is because stamping relies on the punching die and stamping equipment to complete the processing. The number of strokes of an ordinary press can reach dozens of times per minute, and the high-speed press can reach hundreds or even thousands of times per minute, and it is possible to get a punching part with each stamping stroke.

(2) When stamping, because the die guarantees the size and shape accuracy of the stamped parts and generally does not damage the surface quality of the stamped parts, and the life of the die is generally long, the quality of stamping is stable and interchangeable, and it has the characteristic of "one mold".

(3) Stamping can process parts with a wide range of sizes and complex shapes, such as the second hand of a clock, the longitudinal beam of a car, and the cover part, etc. In addition, the cold deformation and hardening effect of the material during stamping makes the strength and stiffness of stamping higher.

(4) Stamping is a material-saving and energy-saving processing method because there are no chips and scraps generated, the material consumption is less, and no other heating equipment is needed.

Classification of stamping process in manufacturing

Stamping manufacturing process is mainly classified and can be divided into two categories: separation process and forming process. The purpose of the separation process, also known as blanking, is to separate the stamped part from the sheet along a certain contour line, while ensuring the quality of the separated section. The purpose of the stamping manufacturing process is to make the sheet plastic deformation without breaking the blank, and to make the workpiece of the required shape and size. In practice, multiple processes are often applied to a workpiece. Punching, bending, shearing, stretching, expanding, spinning and straightening are some of the main stamping processes.

COSMOPlat is aprofessional rotational moulding suppliers, mold manufacturer, we provide metal stamping die design, metal stamping mold, mold stamping, custom metal stamping dies, stamping mould, 3d printing serviceand etc. Want to know more? Please contact us.

Send product request

Other supplier products

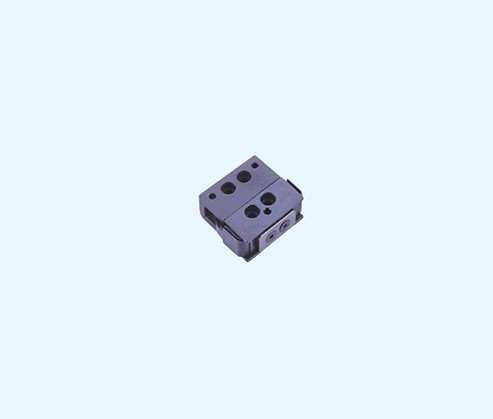

| Square Mold Lock DTP05 | COSMOPlat is wholly owned by Haier Group which is a world-leading provider of solutions to better life. As the world’s first and only IoT eco... | |

| Home | Stamping mold is a special process equipment for processing materials (metal or non-metal) into parts in cold stamping processing, called cold stam... | |

| Gear | COSMOPlat, China mold company, is wholly owned by Haier Industry which is a world-leading provider of solutions to better life. As the world’... | |

| Mold Accessories | Mold accessories are metal accessories specially used in the mold industry, used in stamping molds, plastic molds or FA automation equipment. It ca... | |

| Special Bolt For Positioning Drawing Board | COSMOPlat is wholly owned by Haier Group which is a world-leading provider of solutions to better life. As the world’s first and only IoT eco... |

Same products

| ARM Linux Kernel 2*A7 128M+256M Nand Flash Edge Gateway | Seller: Shenzhen Beilai Technology Co.,Ltd | The ARMxy BL330 series is a versatile industrial ARM controller designed for flexibleI/O configur... | |

| Rail Cant Measuring Device | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| Профилегибочный станок | Seller: Hubei Heavy Industry Equipment Co., LTD | Профилегибочный станокпредставляет собой специальное высокоэффективное технологическое оборудован... | |

| Прессовый станок | Seller: Hubei Heavy Industry Equipment Co., LTD | EZHONG является профессиональным производителем прессов. В настоящее время крупнейший в Китае пре... | |

| Листогибочный станок | Seller: Hubei Heavy Industry Equipment Co., LTD | листогибочный станок с ЧПУ– это ковочное оборудование, используемое для гибки металлическ... |