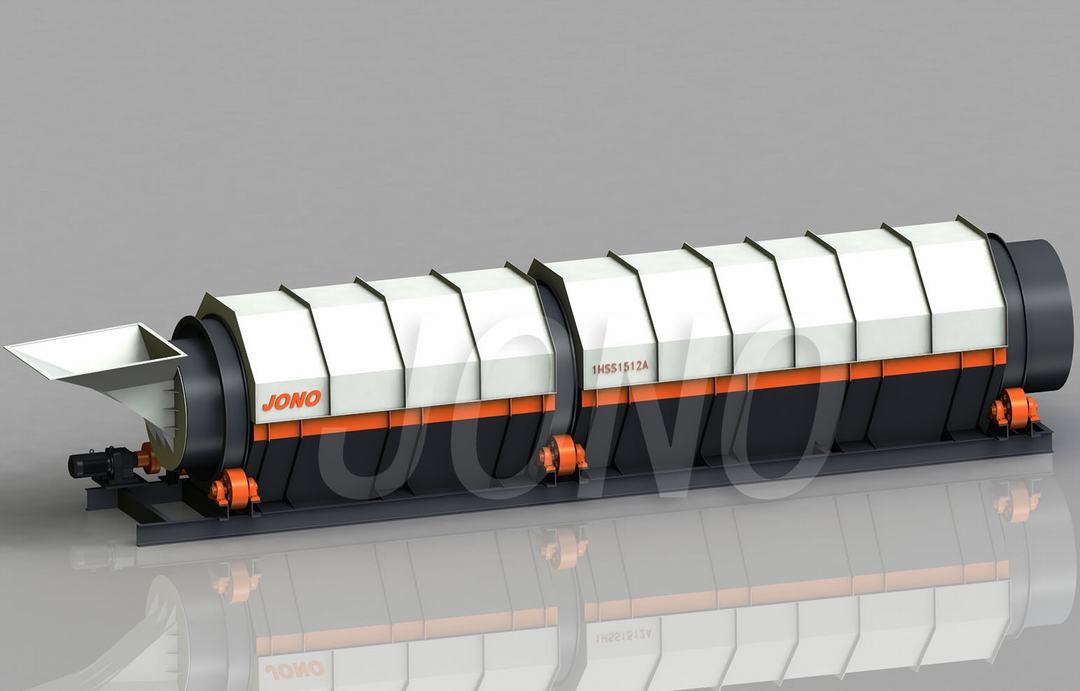

Universal Tilting Rotary Furnace

1HQW universal tilting rotary furnace,a great leap in melting technology.

1HQW universal tilting rotary furnace is used to melt aluminum scraps, lead batteries, aluminum dross, lead dross, and zinc dross. One furnace is able to process all kinds of metal scraps including cans, high quality metal scraps, or low quality metal scraps such as dross, cast parts (with iron), swarf and chips, which cannot be processed by reverberatory furnace , so as to get high quality secondary aluminum from low class metal scraps. High metal recovery rate, especially the recovery rate for rolled waste aluminum could be improved by 3-5%. For companies that are hoping to upgrade from fixed axis rotary melting furnace or reverberatory melting furnace, the universal tilting rotary furnace offers significant advantages with attractive pay back.

The universal tilting rotary furnace, ranging from 1ton to 22tons, could reach maximum throughput at 137tons per day.

The universal tilting rotary furnace is mainly composed of six separated parts: the tilting rotary furnace vessel, refractory lining, combustion system, hydraulic system, PLC control system and flue system (optional). Charging and discharging are both achieved through an opening with the door, which is enclosed with a double pass burner. Auxiliary equipment is assorted automatic charger, automatic slag (liquid) bin and slag skimmer, and automatic ingot casting and palletizing machine. Equipped with the above auxiliary equipment, automatic operation in whole process can be achieved.

Scope of Application

High quality aluminium scraps

Contaminated aluminium scraps with dust, paint or plastics

Mixed metal scraps with ferrous material, such as vehicle ferrous cast parts

Leftover bits and pieces from aluminum casting plants

Swarf and chips from aluminum processing plants

Thin-wall aluminium scraps such as beverage cans, aluminum foils, etc.

Bales of aluminum scraps

Aluminum dross, lead dross and zinc dross

Lead batteries

Metal Bismuth

Features

With the aluminium-dross continuous melting technique, which is created by JONO, you can melt scrap and dross at one batch without skimming the slag. In this way, it reduces labor cost for its completely automatic processing procedure.

25% saving in fuel, with fuel consumption 400KW/MT (oxygen-fuel burner) or 750KW/MT (air-fuel burner)

50% increase in throughput, unrivalled melting speed, especially the melting of aluminum scrap bales

50% saving on slag disposal

50% saving in salt flux

Specifications

|

Model |

[Kg] Aluminum Liquid |

[mm] Furnace Door Dimensions |

[m³] Volume |

[kw] Power |

[RPM] Rotational Speed |

|

1HQW0108A |

1000 |

850 |

0-3 |

||

|

1HQW0211A |

2000 |

1100 |

1 |

0-3 |

|

|

1HQW0313A |

3000 |

1300 |

11 |

0-3 |

|

|

1HQW0514A |

5000 |

1400 |

15 |

0-3 |

|

|

1HQW0815A |

8000 |

1500 |

4 |

0-3 |

|

|

1HQW1018A |

10000 |

1800 |

5 |

22 |

0-3 |

|

1HQW1520A |

15000 |

2000 |

30 |

0-3 |

|

|

1HQW2220A |

22000 |

2000 |

11 |

37 |

0-3 |

One furnace is able to process all kinds of metal scraps; efficient processing of low quality metal scraps such as dross, cast parts (with iron), swarf and chips which cannot be processed by reverberatory furnace

High quality design and manufacture, ensured less maintenance time and longer service

life

High metal recovery, recovery of rolled aluminum bales increased by 3~5%, compared that of reverboratory furnace

Send product request

Other supplier products

| Eddy Current Non-Ferrous Metal Separator | The eddy current separator is composed of conveyor belt, magnetic poles and eddy current drum. The drive motor of the conveyor belt is at the side ... | |

| trommel screen | JONO’s trommel screens have solid construction, and enjoy long life time. The driving wheels are of friction-resistant rubber and yield very ... | |

| Universal Tilting Rotary Furnace | 1HQW universal tilting rotary furnace,a great leap in melting technology. 1HQW universal tilting rotary furnace is used to melt aluminum scraps, l... | |

| Quadruple-Shaft (Shear) Shredder | The cutter chamber of 1PSS quadruple-shaft (shear) shredders are composed of double auxiliary shafts at the upper layer and double main shafts at t... |

Same products

| Automotive Polyester Fabric Tape | Seller: Hebei Top Tape Technology Co.,Ltd | Automotive Polyester Fabric Tape Automotive polyester fabric tapeuses polyester cloth as base ma... | |

| PVC Electrical Tape | Seller: Hebei Top Tape Technology Co.,Ltd | PVC Electrical Tape A thin premium grade plasticized PVC filmcoated with an aggressive rubber ba... | |

| Weldy HG 530-A 230V/2300W CN Plug Universal Kit Hot Air Gun 124.407 | Seller: Weldy China Distributor Co.,LTD | Category: Weldy Hot Air GunPowerful in work mode, power-saving in Eco-ModeInfinitely variable dig... | |

| Weldy HG 530-A 120V/1440W US Plug Universal Kit Hot Air Gun 123.159 | Seller: Weldy China Distributor Co.,LTD | Category: Weldy Hot Air GunPowerful in work mode, power-saving in Eco-ModeInfinitely variable dig... | |

| Weldy HG 530-A 100V/1300W JP Plug Universal Kit Hot Air Gun | Seller: Weldy China Distributor Co.,LTD | Category: Weldy Hot Air GunPowerful in work mode, power-saving in Eco-ModeInfinitely variable dig... |