Rubber Prototyping Parts

Liquid silicone rubber (LSR) molding is a form of injection molding. The liquid silicone rubber is first injected into the mold, then the liquid is thermally cured, cooled and removed from the mold. Compression molding uses uncured rubber that has been preformed into a controlled shape, such as a disc. The mold surrounds the part and compresses it between two plates under high pressure. The high temperature and pressure vulcanize the rubber to cure the part. Pins automatically eject the part from the mold, thereby speeding up production.

Rubber Prototype Parts Applications

1, the application of rapid prototyping technology in the process of new product modeling and design has established a new product development model for the design and development of industrial products.

Rapid Prototyping Fundamentals

Rapid forming technology is a computer-controlled technology based on the principle of discrete and stacking, using different methods of stacking materials to finally complete the forming and manufacturing of parts.

- From the manufacturing point of view, it generates three-dimensional geometric information of parts according to CAD modeling, controls the multidimensional system, and forms prototypes or parts by stacking materials layer by layer through laser beam or other methods.

As a professional precision manufacturing companies, we provide rubber part prototype, prototype silicone rubber parts, prototype rubber parts, rapid prototyping silicone rubber parts, rapid prototype rubber parts, high precision machining, etc.For more information, please feel free to contact us!

Send product request

Other supplier products

| PEEK Non-standard Parts | PEEK Non-standard Parts PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mec... | |

| Punches and Bushings Parts | Punches and Bushings Parts When punching holes with a concave die, the standard of hole diameter is based on the diameter of the convex die. For e... | |

| Nylon Non-standard Parts | Nylon is a tough angular translucent or milky white crystalline resin, as engineering plastics nylon molecular weight is generally 15-30,000. Nylon... | |

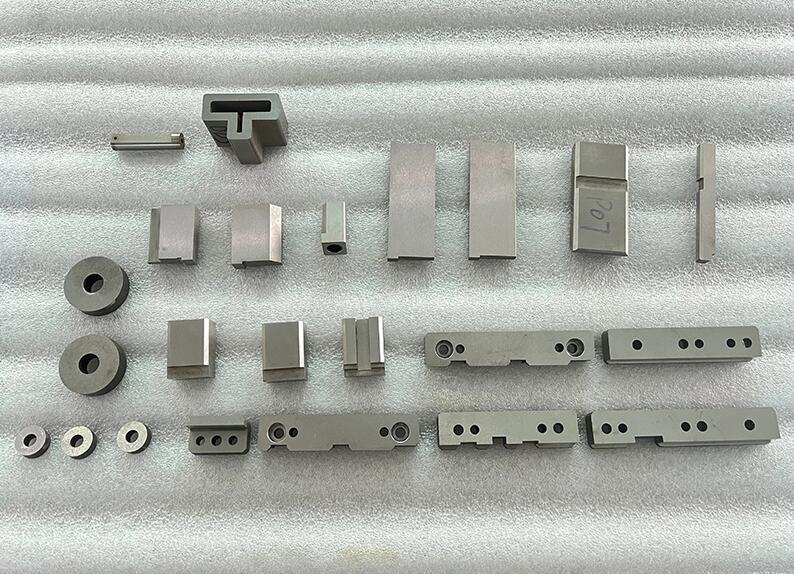

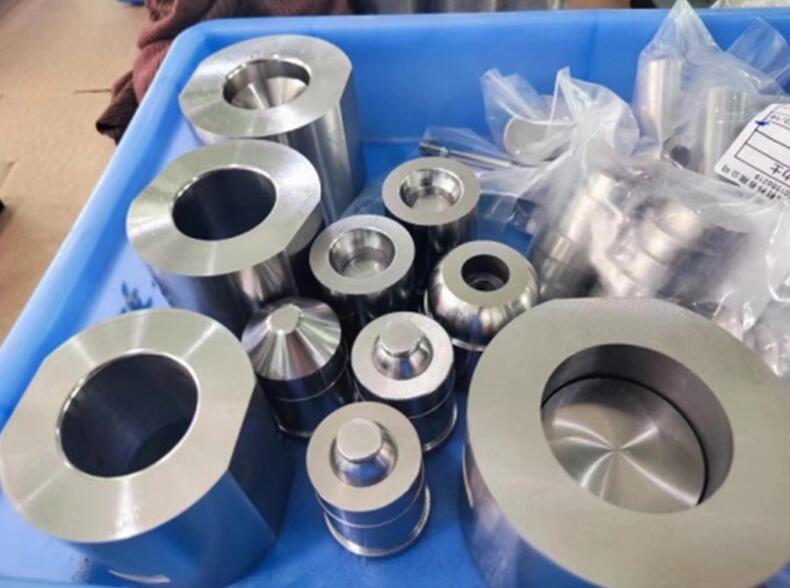

| Carbide Mold Components | Carbide Components We are very capable of customizing punches and dies to produce precision tungsten punches, bushings, ejectors, and die componen... | |

| Metal Stamping Parts | Metal Stamping Components Most of the world's steel is made into finished products by stamping. The body, chassis, fuel tank and radiator sheet of... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | Seller: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | Seller: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I龙门起重机换轨装置 | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| Portable Rail Vertical Tamper | Seller: Wuhan Linkage Track Equipment Co., Ltd | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | Seller: Tangshan Sndou SiC Ceramics CO,Ltd | Riser Tube (stalk ceramic / feeding pipe) as key part of LPDC low pressure die casting machines, ... |