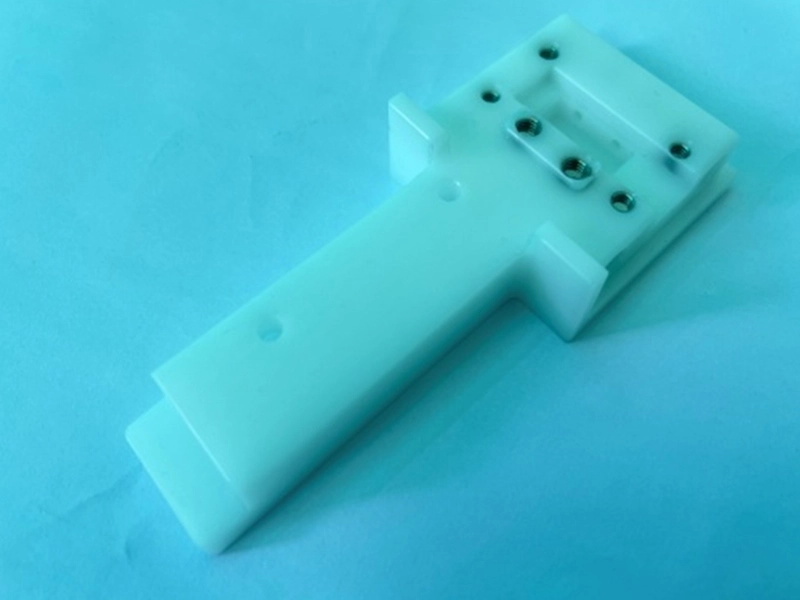

PEEK Non-standard Parts

PEEK Non-standard Parts

PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanical properties, in many special areas can replace metals, ceramics and other traditional materials, in reducing the quality, improving the performance of outstanding contribution to one of today's most popular high-performance engineering plastics, in the field of china peek cnc machining in particular. PEEK material's high-temperature thermal performance is outstanding, can be used for a long time at 260 ℃, an instantaneous use Temperature of up to 300 ℃; its rigidity, dimensional stability, the coefficient of linear expansion is small, close to the metal aluminum materials. That's why it has become the ideal parts for peek cnc machining factories .

What are The Advantages of PEEK CNC Machining?

◆ High-temperature resistance of PEEK CNC

The United States UL certification long-term use temperature of 260 ℃.

◆ Self-lubricating of PEEK CNC

With a low coefficient of friction, it can work without oil lubrication and can work in oil, water, weak acid and alkali medium for a long time.

◆ High strength of PEEK CNC

It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Corrosion resistance of PEEK CNC

It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ Abrasion resistance of PEEK CNC

It has excellent wear resistance in many extremely harsh environments such as high temperatures, high load and strong corrosion.

◆ Hydrolysis resistance of PEEK CNC Machining

◆ Easy processing of PEEK CNC Machining

Parts can be processed directly by an injection molding process. Post-processing such as turning, milling, drilling, tapping and ultrasonic welding can be performed.

◆ Flame retardant of PEEK CNC Machining

◆ Low smoke and non-toxic PEEK CNC Machining

◆ Radiation resistance of CNC machining PEEK

It has excellent resistance to high dose γ-ray radiation, and the mechanical properties can be retained intact, so it can be used as radiation-resistant parts in nuclear equipment.

Electrical performance

◆ Dimensional stability of CNC machining PEEK

Features of PEEK Non-standard Parts

1. Resistance to dissolution in the PEEK high precision machining.

2. Both toughness and rigidity.

3. High temperature, high frequency and high voltage electrical performance conditions.

4. Corrosion resistance, anti-aging.

5. Resistance to hydrolysis, high temperature and high pressure can still maintain excellent characteristics during the PEEK machining.

6. Irradiation resistance wear and corrosion resistance conditions;

7. Resistance to abrasion, anti-static electrical insulation properties;

8. Low soot and toxic gas emissions.

9. Lightweight instead of metal for fiber optic components.

10. Size requirements for precision conditions;

11. Mechanical strength requirements of high components

We are a professional precision machining manufacturer focusing on OEM & ODM customized services of precision quality machining. We own a precision machining factory specializing in precision cnc machining, non-standard spare part processing, metal stamping and metal prototyping.

Other supplier products

|

|

Nylon Non-standard Parts |

Nylon is a tough angular translucent or milky white crystalline resin, as engineering plastics nylon molecular weight is generally 15-30,000. Nylon... |

|

|

Metal CNC Machining Parts |

Metal CNC Machining Parts Custom cnc metal parts are suitable for hand board production and small batch production, various types of parts in large... |

|

|

Plastic CNC Machining Parts |

Commonly used materials for plastic parts processing: ABS, POM, PC, PEEK, Bakelite, Nylon, etc. Specifically can be used for 3D printing, rapid pro... |

|

|

Precision Spare Parts |

We manufacture high-precision parts for customers around the world for virtually all advanced technology manufacturing industries, such as communic... |

|

|

Non-standard Parts |

Standard parts are parts produced in accordance with national standards (GB), industry standards, or foreign standards, mainly for the convenience ... |

All supplier products

Same products