Rubber Prototyping Parts

Liquid silicone rubber (LSR) molding is a form of injection molding. The liquid silicone rubber is first injected into the mold, then the liquid is thermally cured, cooled and removed from the mold. Compression molding uses uncured rubber that has been preformed into a controlled shape, such as a disc. The mold surrounds the part and compresses it between two plates under high pressure. The high temperature and pressure vulcanize the rubber to cure the part. Pins automatically eject the part from the mold, thereby speeding up production.

Rubber Prototype Parts Applications

1, the application of rapid prototyping technology in the process of new product modeling and design has established a new product development model for the design and development of industrial products.

Rapid Prototyping Fundamentals

Rapid forming technology is a computer-controlled technology based on the principle of discrete and stacking, using different methods of stacking materials to finally complete the forming and manufacturing of parts.

- From the manufacturing point of view, it generates three-dimensional geometric information of parts according to CAD modeling, controls the multidimensional system, and forms prototypes or parts by stacking materials layer by layer through laser beam or other methods.

As a professional precision manufacturing companies, we provide rubber part prototype, prototype silicone rubber parts, prototype rubber parts, rapid prototyping silicone rubber parts, rapid prototype rubber parts, high precision machining, etc.For more information, please feel free to contact us!

在线联系供应商

Other supplier products

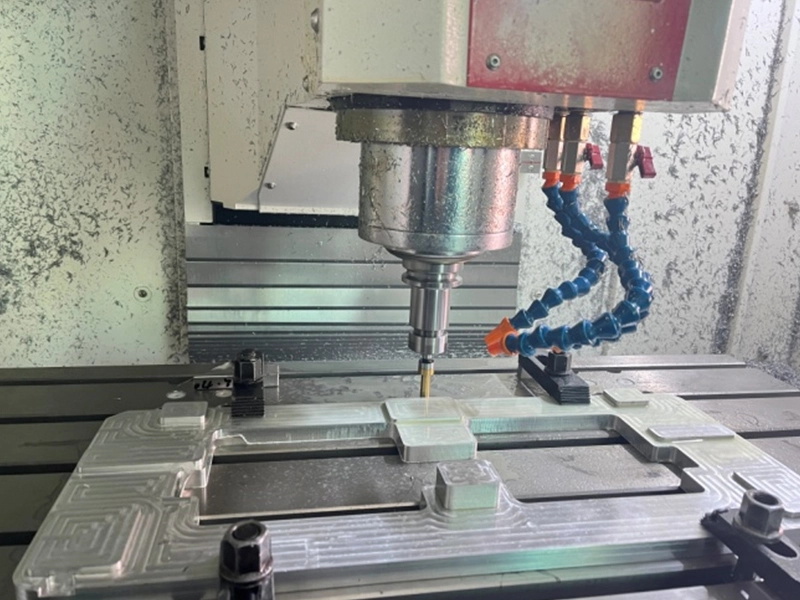

| CNC Prototyping | CNC Prototyping CNC Milling and CNC Turning are excellent CNC machining prototyping options for parts that require prototypes to be evaluated in t... | |

| CNC Milling | CNC Milling CNC Milling is the ideal method for rapid prototyping and for batch manufacturing of plastics and metals. As a cnc milling service sup... | |

| Copper Precision Spare Parts | T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables, conductive screws, shells an... | |

| CNC Turning | CNC Turning OEM CNC turning is the perfect way to make deep holes, machine threads, and all types of cylinder shapes with excellent surface finish... | |

| Metal CNC Machining Parts | cnc metal parts factory/ cnc machining metal parts factory custom cnc metal parts/ cnc machined metal parts/ metal cnc machined parts/ metal cnc p... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | 卖方: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | 卖方: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| 便携式轨道垂直捣固机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | 卖方: 唐山星斗碳化硅陶瓷有限公司 | 星斗公司的升液管作为低压铸造机上的关键部件,具有较好的耐热冲击性、耐腐蚀性、较传统材料寿命更长,性价比更高,可以很好的满足低压铸造行业要求。 |