ECT For Automotive And Aerosapce

NDT Application in Automotive Industry:

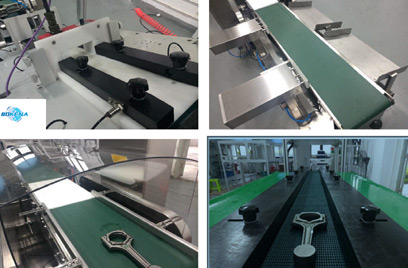

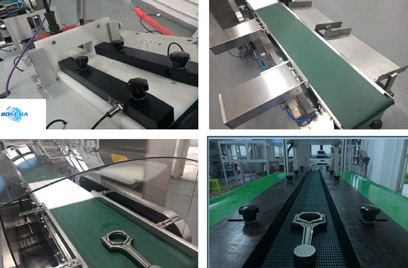

Eddy current testing NDT echnology has been widely used in the detection of metal components in the automotive and aerospace industry. In order to ensure the flight safety of the aircraft, the relevant components must be periodically inspected. The eddy current technology is usually used to detect aero-engine blade cracks, bolts, cracks in the screw holes, multi-layer structure of the aircraft, landing gear, wheels and aluminum skin as the main NDT non destructive testing methods. And subsurface defects, and used to detect defects in the wing joint weld. In the detection, it can effectively suppress the shaking of the probe, and the material is uneven and cause interference signals. Metal magnetic memory testing technology can be used to diagnose the stress concentration of the above components or early damage.

Due to the complex geometry of the auto parts, the equipment is required to have a high level of materials and complicated materials, requiring diverse equipment and high precision. In addition, the production of auto parts is a large industrial production, with certain beat monitoring requirements, and only by reducing the testing costs, can we reduce the automobile production and improve the competitiveness in the domestic and foreign markets. With the development of the national economy, the automobile industry has become a pillar industry in China. Therefore, non-destructive testing technology for eddy current flaw detectors for automotive parts is also receiving increasing attention from manufacturers and researchers. At present, the most widely used non-destructive testing method in the detection of automotive parts is the eddy current hardness testing ultrasonic testing method. In the ultrasonic flaw detection of eddy current flaw detectors at home and abroad, the most used type A ultrasonic flaw detector. It adopts A-type ultrasonic display, which has the advantages of simple and cheap equipment, can locate and quantify defects, and is widely used in production inspection.

However, its flaw detection results are not intuitive, no record, difficult to detect, and many human factors. Seriously affect the reliability of detection. Due to the continuous development of computer technology and electronic devices, the digital acquisition and analysis of the ultrasonic signal of the eddy current flaw detector become possible, the waveform can be recorded and preserved, and the ultrasonic detection of the eddy current flaw detector is positive digital signal processing and imaging direction development. Super-generation image technology is a remarkable new technology. The ultrasonic image of the object can provide intuitively and a large amount of information, directly reflecting the acoustic and mechanical properties of the object, and can also evaluate the mechanical properties of the microstructure of the solid material. Suddenly macroscopic discontinuities.

In short, the NDT non-destructive testing method for automotive parts eddy current flaw detector will develop with the advancement of modern high-tech, to the direction of intelligence, automation and imaging, in order to adapt to the rapid development of modern automobile manufacturing industrial parts quality inspection, testing requirements.

As a et testing ndt equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

Why BKN NDT Testing Equipment

The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a leading high-tech mfl suppliers in China. The company is committed to the development of eddy current, ultrasonic, magnetic flux leakage and various non-standard equipment, holding independent research and development of a number of national patents.

Send product request

Other supplier products

| Bolt Vortex Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Eddy Current Testing Equipment | ECT Eddy current testing used by eddy current testing machine is a non-contact testing method, which mainly uses the electromagnetic field and elec... | |

| Bolt Vortex Sort BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Magnetic Flux Leakage Testing Equipment | What Is Magnetic Flux Leakage Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leaka... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... |

Same products

| UV Detector | Seller: Xinsheng Pharmaceutical Instrument Co., Ltd | The ultraviolet-visible dual-wavelength detector features high sensitivity and a wide linear rang... | |

| Fabric ici pilling and snagging box | Seller: Standard International Group (HK) Limited | Fabric ici pilling and snagging boxis composed of the same speed motor drive, and to maintain the... | |

| Martindale Abrasion And Pilling Tester | Seller: Standard International Group (HK) Limited | To determine the abrasion and pilling resistance of all kinds of textile structures. Samples are ... | |

| Circular Locus Pilling Tester | Seller: Standard International Group (HK) Limited | Testing Standards: GB/T 4802.1. JIG 040-1990 Product Information: The Circular Locus Pilling... | |

| Bean Bag Snag Tester | Seller: Standard International Group (HK) Limited | Bean Bag Snag Tester, to determine the snagging and picking resistance of knitted and woven fabri... |