PEEK in Electronic & Electrical

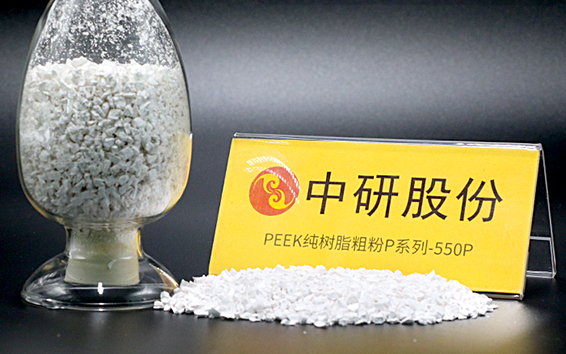

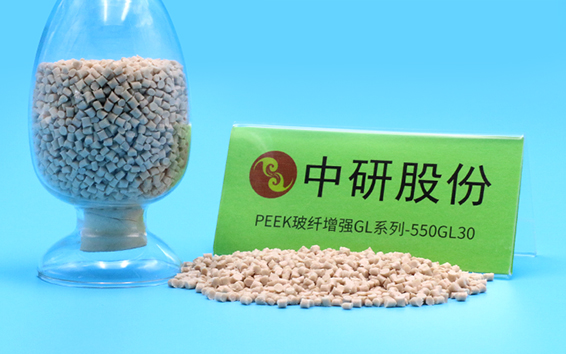

PEEK is a C-level insulating material, keeps excellent insulating properties under high temperature, high pressure, high humidity and other environments, has wave permeability, dimensional stability and self-lubrication, keeps lower dielectric dissipation factor under various frequencies. Zypeek can supply PEEK of insulating grade/ antistatic grade/ ESD grade to meet different needs for electronic and electrical fields.

Applications: Wafer Cassettes/ Component Carriers/ Tweezers/ Circuit Boards/ LED/ Heat Roller Gears/ Cell Antennas/ Card Slots/ Electrostatic Shielding/ Electroplated Rings/ Loudspeaker Diaphragms/ Charger Modules

Emerging Applications of Peek in Electronic and Electrical Fields

Polyether ether ketone (PEEK) from peek material supplieris a high-performance engineering polymer that has been extensively used in the chemical, aerospace, and medical industries. However, recent advancements in PEEK material technology have led to its growing use in the electronic and electrical fields. Emerging applications of PEEK in electronic and electrical fields include additive manufacturing of electronics, flexible electronics, and nanoelectronics.

One of the most exciting applications of PEEKpolymerin these fields is its use in additive manufacturing. Using PEEK filaments allows for the 3D printing of complex electronic components, such as connectors, that can withstand high temperatures and harsh chemical environments. This technology is fueling innovation in various industries, such as aerospace and automotive, where weight, durability, and high-performance function are a priority.

Another emerging application is the use of PEEK in flexible electronics, where it is being used as a substrate for printed electronic devices. Its toughness, and high-temperature and chemical resistance, make PEEK the ideal choice for flexible electronics applications. Moreover, PEEK has also exhibited excellent thermal and mechanical properties for nanoelectronics applications, making it a promising material for future electronic devices.

Overall, the emerging applications of PEEK in electronics and electrical fields suggest a promising future for the use of high-performance polymers such as PEEK in advancing technology.

Advantages of Peek in Electronic and Electrical Fields

PEEK (Polyether Ether Ketone) is increasingly used in the electronic and electrical fields, and it offers several advantages over traditional materials such as Nylon, Teflon, and PVC. Some of the advantages of PEEK in electronic and electrical applications include:

High Temperature Resistance: PEEK has high-temperature resistance up to 260°C (500°F), making it ideal for applications that require high thermal stability.

High Dielectric Strength: PEEK has excellent dielectric properties, such as high dielectric constant, low dielectric loss, and high dielectric strength, making it an ideal material for electronic and electrical applications.

Chemical Resistance: PEEK exhibits exceptional resistance to harsh chemicals and is highly resistant to degradation by hydrolysis, oxidation, and radiation.

Flame Retardant: PEEK is inherently flame-resistant and meets various fire safety standards.

High Strength and Durability: PEEK has exceptional mechanical properties, including high strength, stiffness and fatigue resistance, which make it ideal for applications requiring high strength and durability.

Biocompatibility: PEEK is biocompatible, which makes it an attractive choice for various biomedical and pharmaceutical applications.

In summary, PEEK applications in electronic and electrical fields offers several advantages, including high temperature stability, excellent dielectric strength, chemical resistance, flame retardancy, high strength, and biocompatibility. These properties make PEEK a versatile material suitable for a wide range of electronic and electrical applications in various industries.

If you want to know more kinds of peek board, please visit our website.

Send product request

Other supplier products

| PEEK in Wires & Cables | PEEK has outstanding heat aging properties, good flame retardancy, self-extinguishing, hydrolysis resistance, corrosion resistance, stripping resis... | |

| Color PEEK R&D Series | PEEK ColorR&D Series can be customized according to the customer's own demand. Different PEEK plastic colorscan be chosen for our PEEK raw mate... | |

| CA Series-330CA30 PEEK Carbon Fiber Reinforcement | CA Series-330CA30cf peekcarbon fiber reinforcement is suitable for the production of bushing seals and other products, can be faster from the beari... | |

| Color PEEK R&D Series | PEEK ColorR&D Series can be customized according to the customer's own demand. Different PEEK plastic colorscan be chosen for our PEEK raw mate... | |

| Peek Materials Applications | Peek Material Applications Natural peek materialhas excellent comprehensive properties and can replace traditional materials such as metals and ... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |