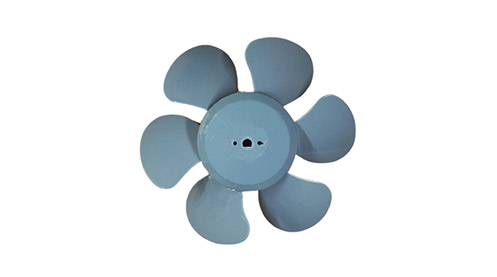

Fan Mold

If the weight of each fan blade is not balanced, large vibration, high noise, and large wear of the rotating shaft will occur during high-speed rotation, which not only seriously affects product performance, but also The lifetime will also be greatly reduced. Therefore, fan products must ensure that the weight of each fan blade is balanced in order to pass the detection of the dynamic balance detector and adapt to the working environment of such products.

High-quality Plastic Fan Mould

Fan blades are usually divided into shaft core circle, blade inner circle, and blade outer circle. If the concentricity of the shaft core circle, blade inner circle, and blade outer circle are not good, the fan blade will vibrate when it rotates, and the rotation will be unstable. Abnormal phenomena such as friction and noise occur around.

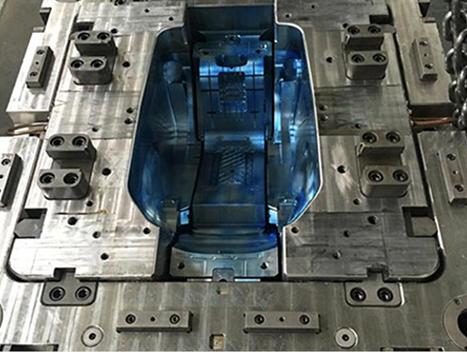

The mold core in the existing fan blade mold is square, and the inner hole in the middle of the square mold core can only be processed by wire cutting. The concentricity cannot be guaranteed, and the concentricity of the inner circle of the blade, the outer circle of the blade, and the shaft core circle cannot be guaranteed, so the quality of the product is not high enough.

Also, the injection fan blade mold must have high precision in centering the fan with the outside frame. GV Mold gives a special solution for the centering location, therefore, after the assembling, the plastic fan and the frame run without any noise of testing.

Basic Information for Fan Mold

Fan MoldSpecification

|

Description |

Fan Blade Plastic InjectionMold |

|

Plastic material |

ABS |

|

Mould dimension(mm) |

320*380*370 |

|

Mould weight (kg) |

200kg |

|

Mould cavity&core steel |

S136 |

|

Nos of Cavity |

1*1 |

|

Manufacture time (day) |

30 days |

|

Mould life |

≥300 000 |

|

Molding cycle (S) |

35s |

|

Mold Characteristics |

High concentricity requirements |

|

Short cycle time |

Design & Key Points for Plastic Fan Mold

The shape of the plastic fan blades is relatively simple. The first requirement is the principle of coincidence of the center of gravity. The size and thickness of all blades should be the same to ensure that the center of gravity of the product is located in the center of the plastic fan part. The second requirement is dynamic balance, that is, balance while rotating. These two requirements put forward higher requirements for the fan mold, that is, on the premise of ensuring the reasonable design of the mold, improving the mold manufacturing process, and improving the mold manufacturing quality.

In addition to paying attention to balance in the mold design process, the balance problem in mold processing is also important. The manufacture of mold cavity & core needs to be directly processed by a high-speed machine, and high-quality processing cutting tools are required. We should make sure each blade has the exact same shape and dimensional tolerances. After all machined, it should be inspected by 3-coordinate, and after all of the dimensions meet the tolerance, then fit the mold and assembly it.

We can provide kinds of injection molding dies for sale, if you have needs, please contact us.

Send product request

Other supplier products

| Plastic Toilet Seat Mold | Toilet seat mouldquality points: cover mold cycle, cover mold life, Parting line whether there are sharp edges? Is the cover wall thickness even? H... | |

| Auto Part Mold | With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by inje... | |

| Mouse Mold | One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which co... | |

| Game Controller Mold | To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time wil... | |

| Game Controller Mold | Game Controller Molds To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, mach... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |