What is the Vacuum Casting?

The china vacuum castingtechnology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silicone mold under vacuum, and is poured under vacuum conditions, such as PU, ABS, etc. Vacuum casting is also used to clone the prototype or copy the piece. It has different types including vacuum mould casting, vacuum pressure casting, vacuum sand castingand so on. This method is especially suitable for small batch production. It is a low-cost solution to solve experimental production and small batch production in a short time, and can also meet the functional test proofing of some structurally complicated engineering samples.

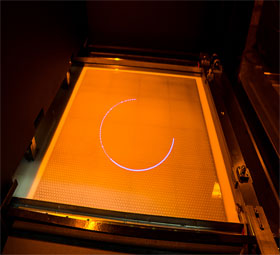

Vacuum Casting Process

Vacuum Casting Process 1

Vacuum Casting Process 2

Vacuum Casting Process 3

Vacuum Casting Process 4

Vacuum Casting is suitable for small batch production, which can greatly reduce production costs, increase production efficiency and shorten the construction period.

Vacuum Casting Process 5

Applications for Vacuum Casting

It is mainly used for product copying and mold making in various industries.

The outer casing of consumer electronics:

The outer casing 1

The outer casing 2

Auto parts:

Auto parts 1

Auto parts 2

Industrial parts:

Industrial parts 1

Industrial parts 2

Vacuum Casting Materials

We offer a wide range of material options: ABS, PP, PC, PMMA, POM, high temperature resistant materials, soft rubber, silicone rubber, etc. Varieties of materials are available to make silicone molds comparable to injection molded parts. The following pictures are rubber, PC-like material, ABS-like material, POM-like material and transparent material.

Advantages of Vacuum Casting

The cost is low and the production cycle of the product is relatively short. Less waste and processing costs are much lower than CNC machining and 3D printing.

It is suitable for the processing and production of small batch products. After making an original version, it can be copied according to the original version, and the production efficiency is high.

Good mold operation. The soft molds after curing are all transparent or translucent, have good tensile strength, and are easy to cut and shape.

The probability of processing failure is small. As long as there is no problem with the original, the copy will naturally not go wrong.

Good repeatability. The silicone for molding has good fluidity before curing, and the fine structure and decoration of the model can be accurately maintained with vacuum defoaming.

We have the world's most advanced vacuum casting equipment, and provide post-processing lines such as polishing, painting and assembly. We can provide small batch production of small and medium-sized parts quikly. If you are looking for reliable vacuum casting service, please contact our professional team at or contact us by visiting our website, we will provide quotes and suggestions free of charge.

ABOUT DUCH GROUP

Duch Group provide customers with competitive solutions such as rapid prototyping china, mass production, small batch production, 3D printing, mold making, and injection molding. With more than 20 years of extensive production experience in the rapid prototyping industry, it is the world's largest rapid prototyping service company.

In 2013, Duch Group was Formally Towards Group Management, which is subordinated to Xiamen Duch Group Co., Ltd., Beijing Duch Technology Co., Ltd., Suzhou Duch Model Manufacturing Technology Co., Ltd., Vistar (Xiamen) Industrial Co., Ltd., Xiamen Magic Trading Co., Ltd., and Xiamen Xindaqian Precision Mould Co., Ltd. with a total registered capital of over 200 million RMB.

Send product request

Other supplier products

| ProtoFab SLA450 DLC | SLA Stereolithography 3d Printer For Sale - Precision Benchmark True-to-CAD Accuracy and Surface Finish True-to-CAD Accuracy and Surface Finish Fab... | |

| Sheet Metal Fabrication Service | What is Sheet Metal Processing? Sheet metal process servicesor sheet metal fabrication includes: folding, shearing, punching, welding, riveting, sp... | |

| PFM800 Automated Vacuum Casting System | It adopts Germany imported Rietschle vacuum pump, ultimate vacuum to ensure complete defoaming; the inner tank selects 5mm thick stainless steel pl... | |

| PFM800 Automated Vacuum Casting System | It adopts Germany imported Rietschle vacuum pump, ultimate vacuum to ensure complete defoaming; the inner tank selects 5mm thick stainless steel pl... | |

| 3D Printing Services | What is 3D Printing Service? 3D printing technology is a collective term for a series of rapid prototyping technologies, the basic principle of whi... |

Same products

| UHF High Power dual junction coaxial isolator | Seller: UIY Inc. | 250 to 1300MHz – Dual Junction Coaxial Isolator Design Features Can be Dual Junction or M... | |

| Petroleum Valve Casting CoreTech Series | Seller: Qingtian Baoli Casting Co., Ltd. | Petroleum Valve Casting CoreTech Seriesoffers a steady foundation for producing valves used in fl... | |

| iFixes iG13 Electric Dispensing Gun | Seller: PHONEFIX technology Co.,Ltd | iFixes iG13 Portable Electric Glue Dispenser compatible with 5CC/10CC/30CC/50CC Tube for dispensi... | |

| Bathroom Bi-stable Sensor Faucet Solenoid Valve | Seller: Zhejiang Fuxin Electrical Technology Co., Ltd. | The Bathroom Bi-stable Sensor Faucet Solenoid Valve is designed for use in sensor-controlled syst... | |

| Wear-resistant carbide guide wheel guide roller | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable p... |