Titanium Alloy 3D Printing Prototyping Service

Introduction to Titanium Alloy 3D Printing Prototyping Service

Titanium alloys are widely recognized for their exceptional strength-to-weight ratio, excellent corrosion resistance, and outstanding performance in high-temperature environments. These characteristics make them ideal for critical applications in aerospace, medical, automotive, and marine industries, where performance and durability are paramount. At NewayAero, we offer state-of-the-art Titanium Alloy 3D Printing Prototyping Services that combine the versatility of additive manufacturing with the advanced properties of titanium alloys to create high-performance prototypes and components quickly and cost-effectively.

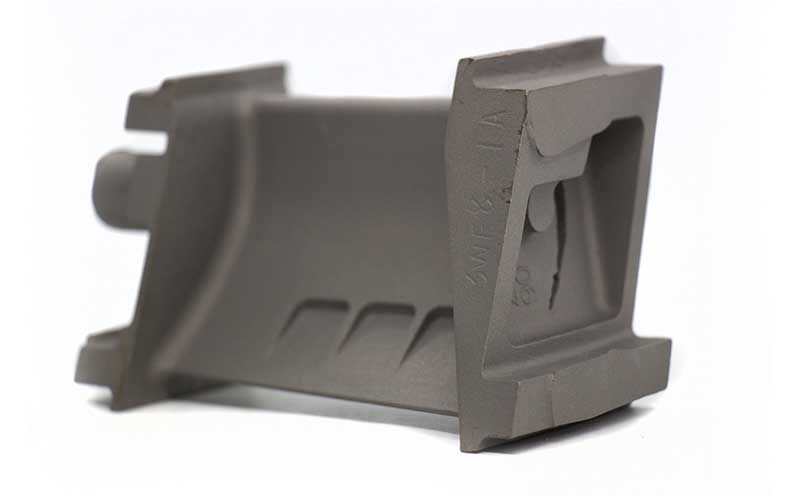

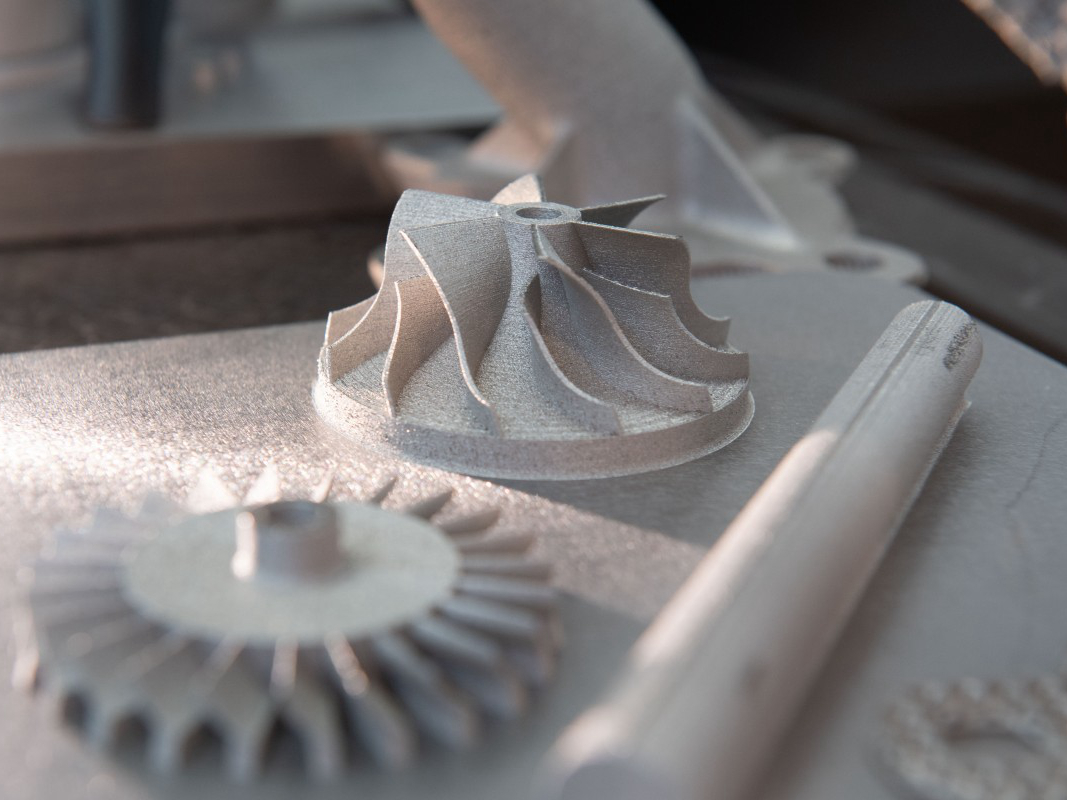

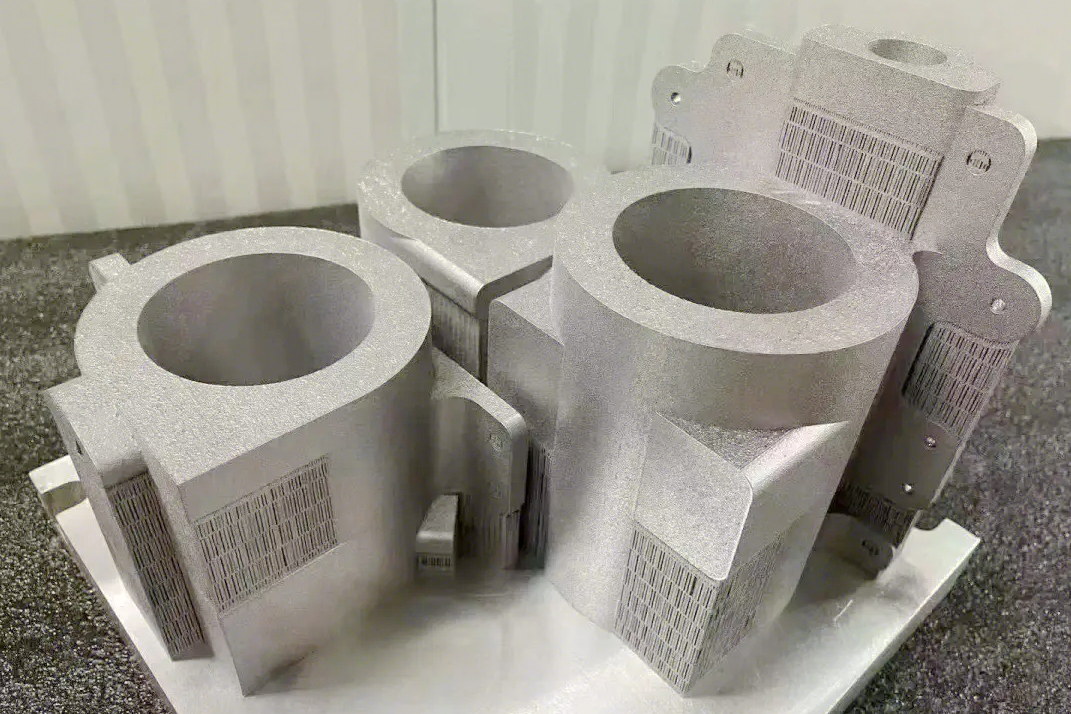

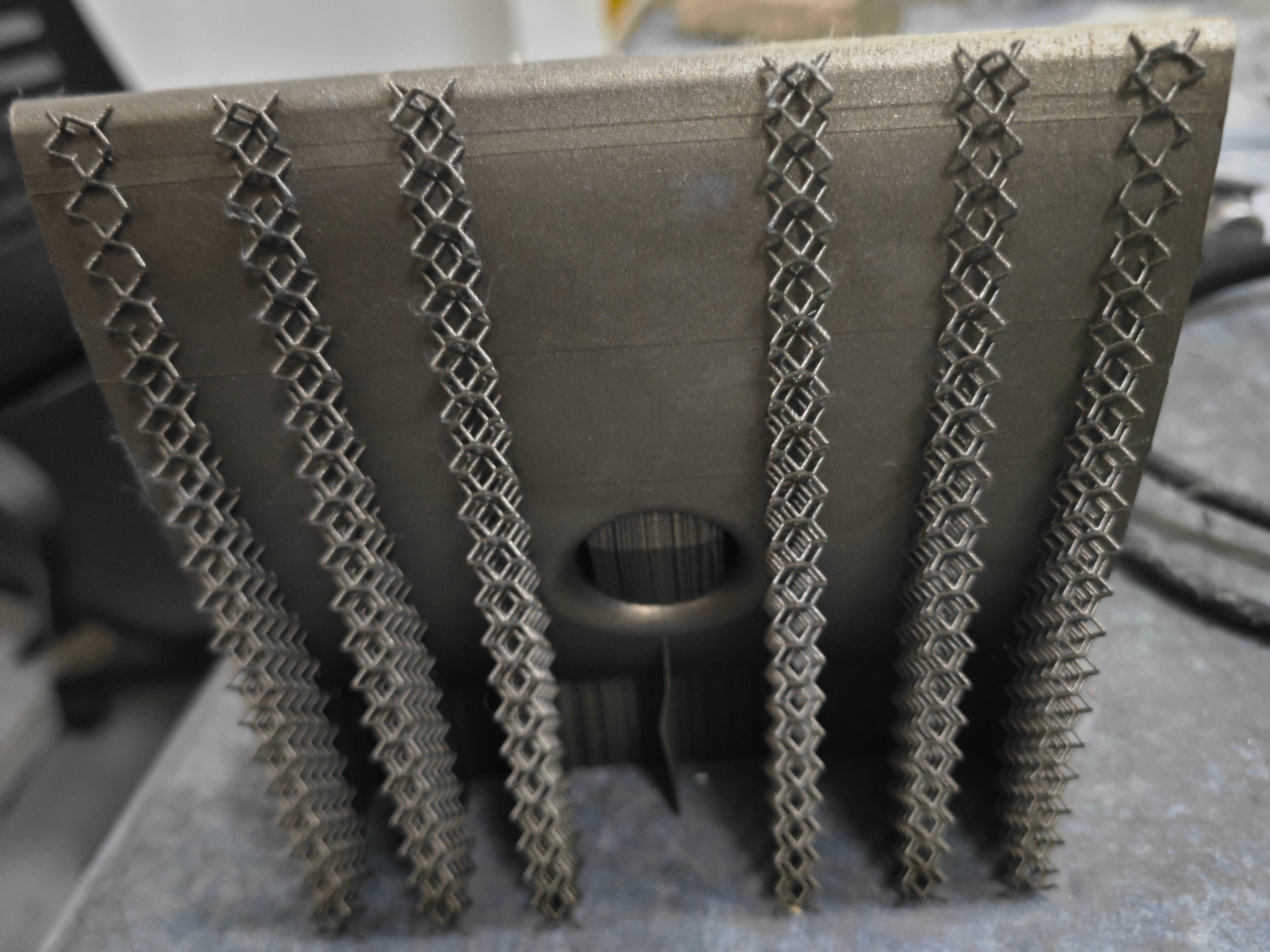

3D printing, also known as additive manufacturing, is a cutting-edge process that builds parts layer by layer from a 3D digital model. This process allows for creating intricate geometries and complex designs that are difficult, if not impossible, to achieve using traditional manufacturing methods such as casting or machining. In titanium alloy 3D printing, fine titanium alloy powder is precisely melted and fused using high-powered lasers or electron beams, depending on the specific technology used, such as Selective Laser Melting (SLM) or Electron Beam Melting (EBM). Each material layer is deposited, melted, and solidified before the next layer is added, gradually building the part from the ground up.

One of the main advantages of using 3D printing for titanium alloy parts is optimizing material usage by producing lightweight, high-strength structures. This is particularly beneficial in aerospace and automotive industries, where weight reduction is crucial for performance and fuel efficiency. Additionally, 3D printing allows for rapid prototyping, enabling engineers to test quickly and iterate designs without expensive tooling or molds, reducing lead times and costs.

After printing, the titanium parts undergo post-processing steps such as heat treatment, surface finishing, and stress relief to enhance mechanical properties like strength, fatigue resistance, and corrosion resistance. These steps ensure that the final product meets the specific requirements of the industry application, whether for aerospace turbine components, medical implants, or high-performance automotive parts.

Common Grades of Titanium Alloys for 3D Printing

Common grades of titanium alloys used in 3D printing include:

Titanium Alloy Grades

- Ti-6Al-4V (Grade 5)

- Ti-6Al-4V ELI (Extra Low Interstitial)

- Ti-3Al-2.5Sn

- Ti-5Al-2.5Sn

- Ti-10V-2Fe-3Al

- Ti-13V-11Cr-3Al

For example, Ti-6Al-4V is one of the most widely used titanium alloys in aerospace and medical applications due to its high strength, corrosion resistance, and biocompatibility. Ti-6Al-4V ELI is specifically designed for medical implants, offering higher purity and fewer impurities, while alloys like Ti-10V-2Fe-3Al are used in aerospace for high-stress applications due to their superior fatigue strength and toughness.

NewayAero’s Titanium Alloy 3D Printing Prototyping Services enable industries to rapidly develop and test complex, high-performance titanium parts, streamlining product development and reducing time-to-market while maintaining the highest standards of quality and precision.

Send product request

Other supplier products

| Custom Stamping Service | Our custom stamping service provides cost-effective solutions for your metal component needs. We can create high-quality parts at a fraction of t... | |

| Inconel alloy Superalloy CNC Machining Services | Introduction to Inconel Alloy Superalloy CNC Machining Services Inconel alloys are a family of high-performance, nickel-based superalloys known fo... | |

| Single Crystal Alloy Vacuum Investment Casting Services | Introduction to Single Crystal Alloy Vacuum Investment Casting Services Single crystal alloys are a critical class of materials used in advanced a... | |

| Custom Sand Casting Service | Create high-quality custom parts with our sand casting services. Our experts will provide the perfect solution for your needs. Request a quote to... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components Inconel alloypowder metallurgy(PM) tu... |

Same products

| Petroleum Valve Casting CoreTech Series | Seller: Qingtian Baoli Casting Co., Ltd. | Petroleum Valve Casting CoreTech Seriesoffers a steady foundation for producing valves used in fl... | |

| Bathroom Bi-stable Sensor Faucet Solenoid Valve | Seller: Zhejiang Fuxin Electrical Technology Co., Ltd. | The Bathroom Bi-stable Sensor Faucet Solenoid Valve is designed for use in sensor-controlled syst... | |

| Wear-resistant carbide guide wheel guide roller | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable p... | |

| High precision tungsten carbide guide wheel guide roller | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable... | |

| Portable Wooden Sleeper Drilling Machine | Seller: Wuhan Linkage Track Equipment Co., Ltd |