Refractory raw materials processing procedures

Refractory raw materials processing is to enter the factory of various shapes and sizes of refractory raw materials (including raw ore and clinker) into the required size, and remove impurities mixed with refractory raw materials for the preparation of brick use. Refractory raw material processing include: selection of refractory raw materials, crushing, grinding, fine grinding and screening.

The selection of raw materials into the plant

The selection of refractory raw materials into the plant there are two main purposes: (1) selected mixed in the raw materials in the debris, under burning material, not burning fuel and tumor blocks, etc .; (2) According to the appearance of refractory raw materials Features are stacked for ease of management and use.

Broken smashing purposes

The mechanical method (or other methods) exerting external force on the large refractory raw materials so as to fragment them into small pieces or fine powders is called raw material crushing and pulverizing.

Usually two or three broken crushed. That broken - broken pieces of material from 250-300mm broken 40-50mm;

Crush - Material block size from 40-50mm crushed to 4-5mm;

Fine grinding - finely ground material size from 4-5mm to less than 0.088mm.

The purpose of crushing is to prepare massive refractory raw materials into pellets and fine powders with a certain granular composition so that powders of different compositions are prepared and mixed uniformly; the specific surface area of the raw materials is increased and the physicochemical reaction speed is increased.

Impact broken broken factors

There are two factors influencing the crushing and breaking: on the one hand, it is related to the structural properties of the refractory raw material itself - strength, hardness, homogeneity, cleavage and plasticity; on the other hand, it is related to the characteristics of the equipment used, Broken product size requirements are closely related. Generally, the crushing ratio (the ratio of the average diameter of the material before it is crushed to the average diameter of the material after it is crushed) is lower, and the lower the productivity of the machine is.

Broken crushing process and characteristics

There are usually two types of crushing processes: open flow and closed flow. Open flow advantage is the simple process, refractory raw material only through the grinder once. The disadvantage is the power consumption, low productivity, and produce excessive flour, is not conducive to improving the quality of products. Although there is no above closed-flow shortcomings, but the process is complex, requiring more ancillary equipment. The advantage is higher crushing efficiency, easy to reach the degree of particle material requirements. Usually refractory raw materials broken open-flow, and crushed by closed-flow circulation crush.

At present, all over the refractory plant commonly used is a single closed-flow or multi-flow. The former is suitable for medium and small factories with many kinds of products, and the latter is suitable for producing large quantities and stable products.

在线联系供应商

Other supplier products

| Ceramic Fiber Blanket | DescriptionKnown as aluminum silicate fiber blanket, ceramic fiber blanket mainly consists of selected high quality spun ceramic fiber, double side... | |

| Factors to consider when selecting insulation materials | In choosing the insulation material for industrial furnaces, it is necessary to have a good understanding of the properties of the material itself ... | |

| high quality! refractory silica fire brick for furnace crown | Product Description ith dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size 1)Silicon oxide is abov... | |

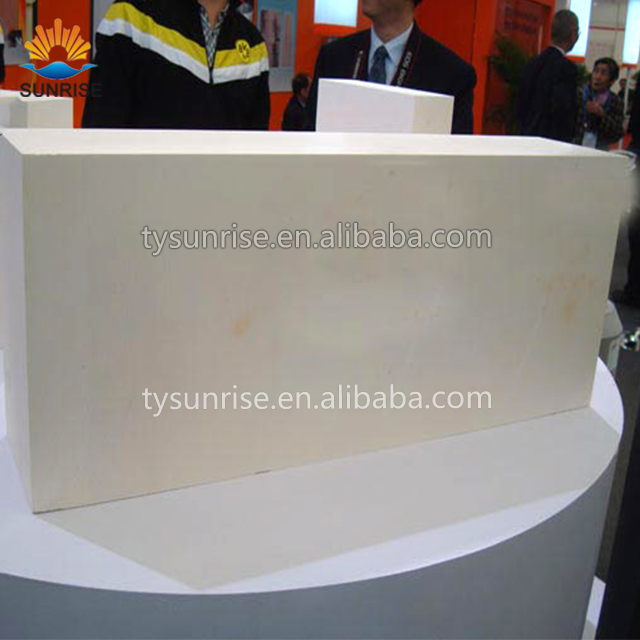

| Corundum Block TY-G98 | Main mineral component of corundum brick is corundum phase, it has excellent physical property in high temperature, resistance to chemical corrosio... | |

| fireproof case fused cast azs refractory brick for glass furnace, AZS--33,36,41 | Glass furnace brick refractory material AZS brick Fused Cast AZS are the most widely used materials both in glass contact and superstructure of ... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |