Factors to consider when selecting insulation materials

In choosing the insulation material for industrial furnaces, it is necessary to have a good understanding of the properties of the material itself in order to integrate the characteristics of the furnace itself and choose the suitable insulation material for the furnace. The insulation materials on the market can be divided into two major categories. One is the organic insulation material. The highest temperature used is 100°C. It is used only on the cryogenic insulation pipe for freeze protection; the other is the inorganic insulation material. The maximum operating temperature can be as high as 600°C or higher.

Thermal insulation performance analysis

1, density

The density of the insulation material does not mean the density under the normal temperature conditions, it refers to the density of the insulation material at the temperature of 110°C when it is dried loosely (that is, it has pores). For soft and semi-rigid insulation, there are three main densities: production density, transportation density, and installation (compression) density.

2, the coefficient of linear expansion

The coefficient of linear expansion refers to the relative increase in the linear dimension of each degree of increase in temperature when the insulating material is heated.

The linear expansion coefficient of the heat-insulating material is closely related to its thermal stability. When the temperature changes violently, a large linear expansion coefficient may cause damage to the heat-insulating material. In thermal design, certain expansion gaps need to be reserved for such materials.

3, thermal conductivity

The thermal conductivity is the main performance of the insulation material. It refers to the heat flux passing through the insulation material with an area of 1m2 and a thickness of 1m under a stable heat flow. The heat flow through the insulation material when the temperature difference between the two surfaces is 1°C within a 1h interval.

The basis for selecting the insulation material

1, thermal conductivity of insulation materials

At the same use temperature, the smaller the thermal conductivity of the thermal insulation material, the better the thermal resistance. In the thermal insulation design, it is one of the main basis for selecting the thermal insulation material.

2, the maximum use temperature

The maximum use temperature refers to the limit temperature that the insulation material can withstand during long-term safe and reliable operation, not the melting temperature or deformation temperature of the insulation material.

3, the hardness of insulation materials

For soft or semi-rigid insulation materials, the compression of the materials inevitably involves in the construction process, which will lead to changes in the thermal conductivity, and ultimately cause access and construction.

4, the density of insulation material

Choosing insulation materials Not only kilns are considered for their production density, but also for transportation density and their installation (compression) density.

5, the PH value of insulation material

In the selection of insulation materials, insulation materials with pH>13 or PH=7 should be selected as much as possible.

6, the composition of insulation materials

The selected insulation material is safe, non-toxic, radiation-free, and stable.

In short, when selecting insulation materials, not only the above factors are considered in the kiln, but many uncertainties need to be considered.

Other supplier products

|

|

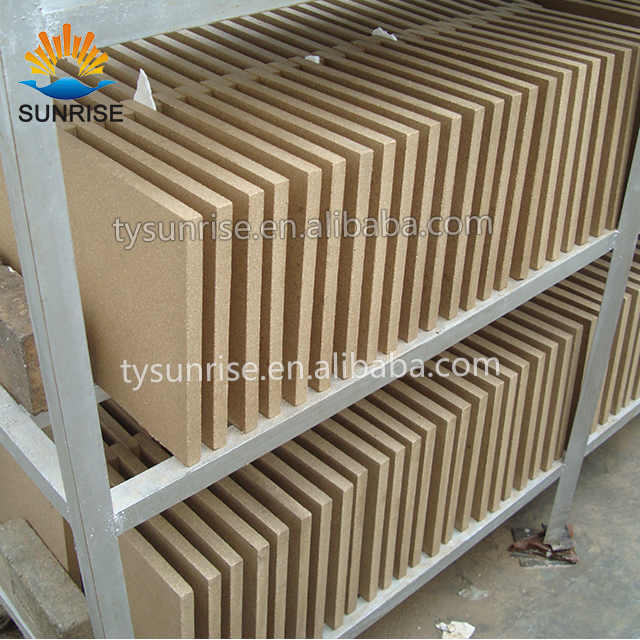

The characteristics of mullite insulation bricks |

1. Foaming Foams for Lightweight Heat Preserved Bricks Bubbles with uniform bubble diameters can be obtained. 2. The foam is independent, and it is... |

|

|

Glass Mould Brick |

With the development of the world automobile industry in recent years the technology on rearview mirror is also greatly improved, as demands a high... |

|

|

Cast Big Sillimanite Block |

Feature

►Sillimanite Big Block:

Due to its good chemical stability, high fire resistance, big intensity and good high temperature performance, it... |

|

|

Hard Magnesium Silicate Insulation Board Used for Electrolyt |

HardMagnesium Silicate Insulation Board isproducedby mixinga blend ofultra-low conductivity raw materials withaninorganic polymerbinder.As a finish... |

|

|

Fused cast Alumina Block TY-M |

Fused cast Alumina Block TY-M is formed by the compact structure of alpha alumina and beta alumina crystals in a most ideal proportion which is app... |

供应产品

Same products