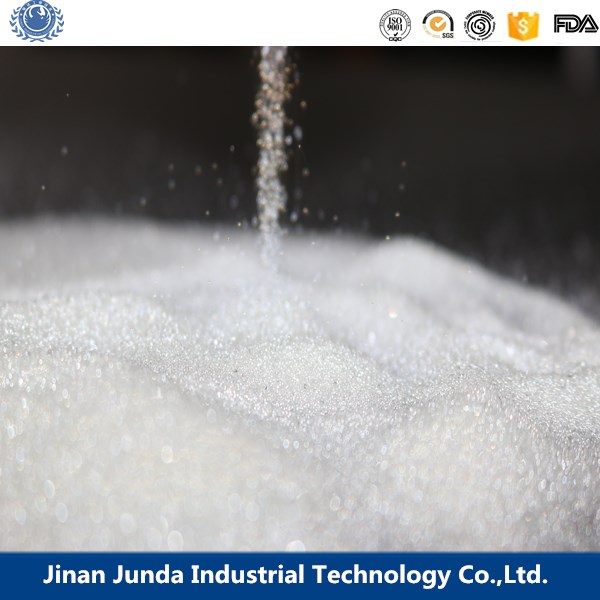

Glass beads for sandblasting

HONEST HORSE Companies use glass bead blasting, which is a type of abrasive blasting, for surface finishing, specifically to prepare metals by smoothing them. Bead blasting provides superior surface cleaning to remove paint, rust and other coatings.

The glass bead blasting process is environmentally-friendly and chemical-free and can be used to detect weld and solder flaws. Advantages of using glass bead blasting include:

• A large variety of grades available for different jobs and profiles.

• Does not interfere with coatings as it is no-reactant.

• It leaves no residue or embedded contaminants, and also does not cause any dimensional surface change.

• Improved corrosion resistance and the ability to smooth away surface flaws.

• No detectable crystalline silica.

在线联系供应商

Other supplier products

| Steel grit G25 for shot peening strenghening | Steel grit Surface preparationSurface preparation is as a series of operations including cleaning and physical modification of a surface. Steel sho... | |

| Garnet sand 80# for waterjet cutting | HONEST HORSE garnet sand isalmandite garnet, one of the hardest minerals. We closely cooperate with the leading waterjet equipment manufacturers to... | |

| Garnet sand 30-60# for sandblasting | Garnet sand blasting abrasive has features of good color, high hardness, long lifetime, self-sharpening,high grinding efficiency, low consumption, ... | |

| steel shot S230 for shot blasting | Steel Shot is manufactured by melting selected scrap in electric induction furnace. The chemical composition of molten metal is analyzed and strict... | |

| Glass beads for sandblasting | HONEST HORSE Companies use glass bead blasting, which is a type of abrasive blasting, for surface finishing, specifically to prepare metals by smoo... |