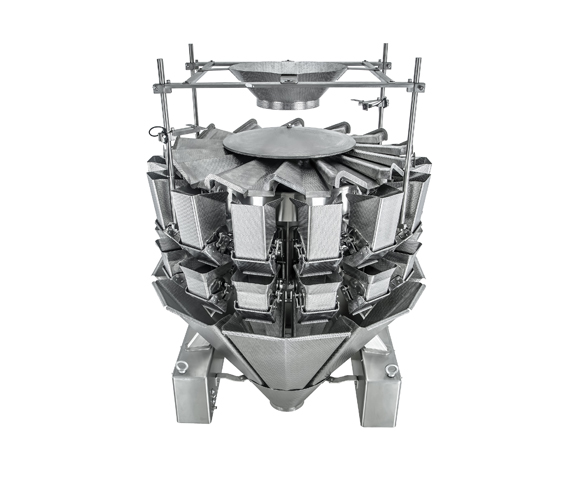

Noodle Product Multihead Weigher

Advantages of Noodle Product Multihead Weigher

Waterproof noodle weigher with widely used on noodles project, which has following advantages:

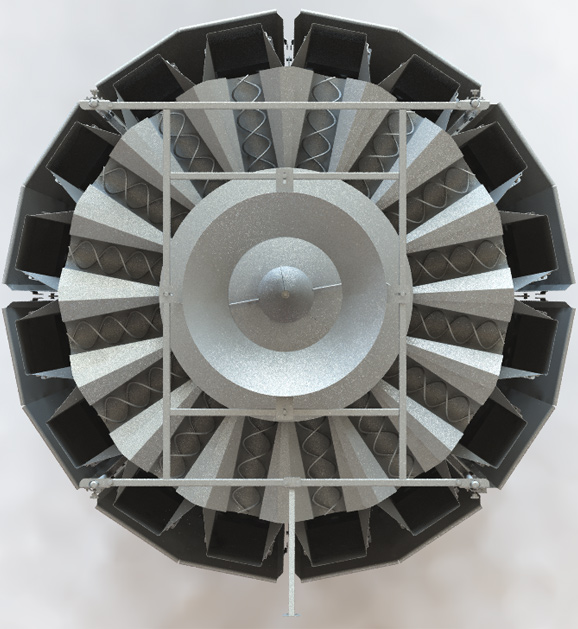

Special made rotary topcone with speed controllable and time adjustable

Special made linear feeder trays to better control the feeding of noodle

With IP66 waterproof (SGS approval) to improve the performance on noodel project

Specifications of Noodle Product Multihead Weigher

Model: AC-6B14-4A-18

Generation: 4G

Weighing range: 15-3000g

Accuracy: +/-0.5-2g

Max speed: 140bpm

Power supply: 220V, 50、60HZ,2KW

Hopper volume: 3L

Monitor: 10.4 inch

Dimension(mm): 1600*1210*1550

Solutions of Noodle Product Multihead Weigher

Noodle Product Multihead Weigher

Application includes many kinds of dry and wet products, such as snacks, confectionery, nuts, chips, flakes, cookies, beans, pet food, etc.

Guangdong High Dream Intellectualized Machinery co., ltd. is a professional auger filler machine manufacturer. We provide Loss-in-Weight Feeder, Metal Detector, Check Weigher, high dream multihead weigher, pasta multihead weigher, linear multihead weigher and so on. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Noodle Product Multihead Weigher | Advantages of Noodle Product Multihead Weigher Waterproof noodle weigher with widely used on noodles project, which has following advantages: S... | |

| Noodle Product Multihead Weigher | Waterproof noodle weigher with widely used on noodles project, which has following advantages: Special made rotary topcone with speed controllable... | |

| 4G PLUS High Performence 10 Heads Multihead Weigher | Main Feature of 4G PLUS High Performance 10 Head Weigher User-friendly touch screen with multiple languages for choice. This multihead weigher ma... | |

| Meat Product Multihead Weigher (Screw Feeder) | Application of Meat Weigher Both 6 head & 8 head linear weigher with widely used on sticky & fresh products, fragile and difficult moving ... | |

| Sticky Product Linear Weigher ( Scraper Hopper) | Application of Sticky Product Linear Weigher Stick shape weigher with widely used on chopsticks/toothpicks/steel nails/dog food/stick tablespoons p... |