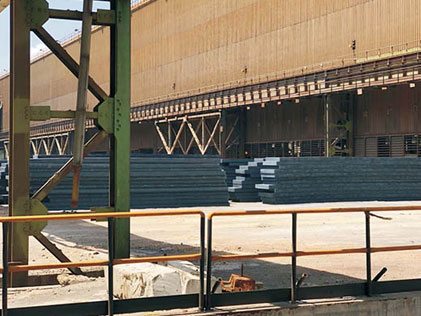

Hot Rolled Steel Sheet

HUAROSteeloffers high-quality steel product, steel raw material and other raw material. We depend on Huaruo worldwide supply chain tointroduce and export our superior products.

Hot Rolled Steel Sheet Production Process

The production procedure of HRS is generally as follows: Iron making → steel making → continuous casting (or die casting) → hot rolling process

Hot Rolled Steel Sheetproduction is a rolling procedure that relates rolling steel at a high temperature (usually above 1700°F) and over the recrystallization temperature of hot rolled sheet. When the steel heating temperature is higher than the recrystallization temperature, it can be formed and shaped easily, and the steel can be made to larger sizes. Hot Rolled Steel Sheet is usually cheaper than cold rolled steel because of the fact that it is usually manufactured without any delays and then does not require reheating of the steel (as with cold rolling). As steel cools, Hot Rolled Steel Sheet contracts slightly compared to cold rolling, so there is less control over the size and shape of the finished product.

Description of Hot Rolled Steel Sheet

Because of its much simpler processing method, hot rolled steel can be easily shaped and formed in any desired form. Hot rolled sheet is one of the most variety of steel in the industry. Because of its ductility, this hot rolled sheet is very advantageous in the production of structural or sectional modules. The main characteristics of hot rolled steel sheets are similar to those of hot rolled steel coils, very similar production procedures and thickness, width, and length define similar physical characteristics, but the post-processing methods are different. In addition, determine the final application and corresponding processing equipment.

Application of Hot Rolled Steel Sheet

Used in welding and boiler making, hot rolled steel is ideal for construction materials such as railroad tracks and l-beams. Another advantage of hot rolled steel is that the surface finish of hot rolled sheet is not an issue.

Typical uses consist of:

lStructural sections

lWhether resistant structures

lPressure vessels

lStructural parts, vehicle chassis wheel rings

lShipbuilding, marine application

在线联系供应商

Other supplier products

| Copper Cathode | Description of Copper Cathode Copper is one of the basic chemical elements. In its nearly pure state, copper is a reddish-orange metal known for i... | |

| Pickled Coils | As a reliable and professional steel raw material suppiler, Huaruo aims to manufacture the best quality steel productsto satisfy various needs of t... | |

| Hot Rolled Strip | Description of Hot Rolled Steel Strip Hot Rolled Steel Strip generally refers to a coiled steel strip having a thickness of 1 to 20 mm, and the wi... | |

| Description of Iron Ore Concentrate | Iron Ore Pellets for Sale Iron ore concentrateis produced from the magnetite iron ore in the beneficiation process. When the iron ore is mined, fi... | |

| Steel Product | Steel Products List Steel is one of the oldest metals forged by humans and is still the most reliable and widely used material in manufacturing ... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |