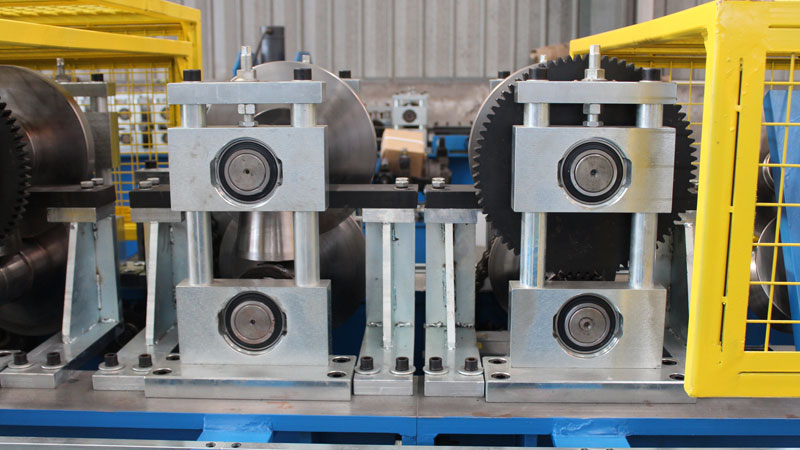

Garage Door Guide Rail Roll Forming Machine

This series ofgarage door roll former is used to make various guide rails. A guide rail is a device or mechanism to direct products, vehicles, or other objects through a channel, conveyor, roadway, or rail system. Our light steel frame machinecan make guide rails for garage doors, rolling shutter doors, elevator or lift shafts, and so on.

Features and Advantagesof Garage Door Guide Rail Roll Forming Machine

Our light gauge steel framing machinesis specially designed for forming rolling shutter door panels under mass production.

Productionspeed: 20/30/40/50/60 m/min optional.

Working with a non-stop flying cutand a fullautomatically stacking system, its max production speed can reach 60m/min.

Cassette-type platform and quick-change machine base formulti-profile purposesare available for further choice.

Certified with Multi-Patents; CECertified, EUROPEANquality standard

Ready machines in stock for prompt delivery

Suitable Coil Sheet Material forGarage Door Roll Forming Machine

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 0.8-1.3/1.0-1.6/1.5-2.0 (mm)

Yield Strength: 230-300 (MPa)

Width: as profile requests

Production Line Components and Parameters ofGarage Door Roll Former

|

Decoiler |

5t/8t/10t/15t Motor/hydraulic motor/passive (optional) |

|

Filming covering device |

optional |

|

Front shear |

optional |

|

Lubricating device |

no need |

|

Roll forming system |

20/30/40/50/60 m/min (optional) |

|

Safety cover |

optional |

|

Post cutting |

Motor/hydraulic (optional) |

|

Output System |

Manual supporter/ Automatic Stacker (optional) |

|

Stack Master |

(Output direction) Lateral/Longitudinal (optional) |

|

Hydraulic system |

Power supply for decoiler /post-cutting system |

|

Electric control system |

MITSUBISH/ SIEMENSE/AMS (optional or as requested) |

The Working Flow ofGarage Door Roll Forming Machine

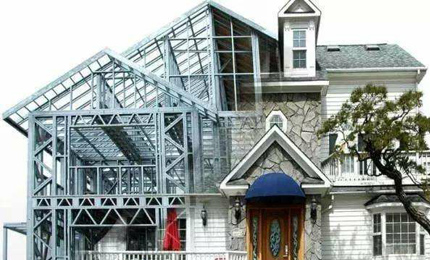

Garage Door Guide Rail Roll Forming Machine Application

Garage Door Drawings

Specification ofGarage Door Roll Forming Machine

|

Machine Condition |

Fully New, A-Grade quality |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator |

needed 1-2 persons |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 15t |

|

Dimension |

(L*W*H) about 25*3*2m |

|

LOADING SIZE |

Normally need 1 x 40' container. |

|

Equipment Color |

Normally Blue/White, or as requests; |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

Our company, Hangzhou Roll Forming Technology Co, Ltd, has engaged in desingning and manufacturing roll forming, coil processing equipment and tube/pipe mill for 17 years. We provide roll forming production line, cold roll forming machineand etc.

在线联系供应商

Other supplier products

| Metal Roofing Tile Former | This series of metal tile roll forming machine is used to make metal roofing tiles. Mainly including a step-pressing system, our steel roofing mach... | |

| Hydraulic Shearing Machine | (1) The knife holder moves along the vertical line, because there is no forward inclination, so the upper blade section must be processed into a ... | |

| HIGHWAY GUARDRAIL & FENCE POST ROLL FORMING MACHINE | HIGHWAY GUARDRAIL & FENCE POST ROLL FORMING MACHINE This series of rolling guardrailmachines are equipped with a quick-change machine base for... | |

| Fully Automatic CZ Purlin Roll Forming Machine | The fully automatic C/Z steel integrated machine is also called the C/Z interchange molding machine, and C and Z interchange purlin machine. The fu... | |

| AUXILIARY EQUIPMENT | The Auxiliary equipment refers to machines for metal sheets before being formed and profiles after formed. The equipment for metal sheets includ... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |