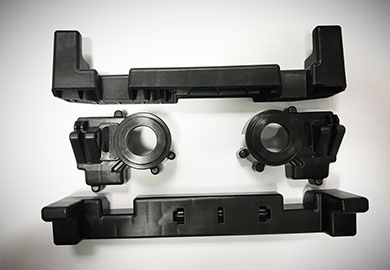

2K Mould

We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sales service. We have an precision injection moldingprocess with a component load capacity of up to 2 kg in a large machine, carrying out assembly of complex component modules and offer painting and other finishing services all accompanied by the most sophisticated of logistics processes.

2k injection molding is a manufacturing process that refers to molding two materials or colors into one plastic part.

This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of the 2K moulding process is generally according to cost and customization considerations.

Features of 2K Mould

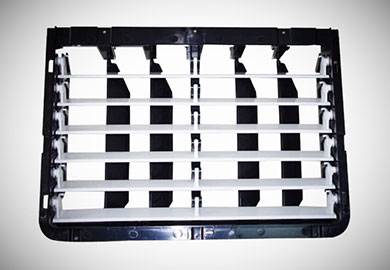

Physical appearance

The physical appearance of 2K injection molding about aesthetic value or beauty is high as many colors can be blended in the molding stages.

Cost-efficiency

Because all 2K molding manufacturing procedures are finished in the injection stage, it can save plastic injection molding cost and lower the labor and material fees.

Customization

We can provide custom-made plastic injection molding products to meet your demanding need. It is possible to finish the products with 2K plastic injection moulding with softer edges.

The Specification of 2K Mould

|

Part material |

PC + ABS |

|

Cavity |

1L + 1R |

|

Mold accuracy |

+ / - 0.01 |

|

Mold steel |

|

|

Moldbase steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

6 lifters |

|

Exporting country |

Germany |

|

Delivery time |

4 weeks |

|

Mold quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

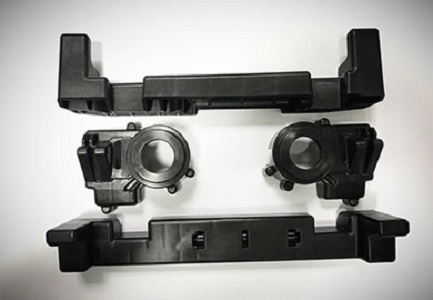

How does 2K Mould Work?

Since there are a lot of benefits of 2K injection molding, can I learn more about the working principle of 2K mould?

2K injection moulding operates in one machine which is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The 2K plastic injection moulding is then rotated automatically and another type of plastic is injected from a second nozzle into the mold. When using the 2k injection molding technology process, material selection is very important to the injection.

在线联系供应商

Other supplier products

| Electronics Product Part | Electronics Product Part With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injectio... | |

| Automotive Part | We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sale... | |

| Home Appliance Part | The development and design of plastic injection molding home appliance parts pay attention to safety and health. In-home appliance industry, polypr... | |

| CNC Components | Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. If we want to ch... | |

| Electronics Product Part | With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can... |