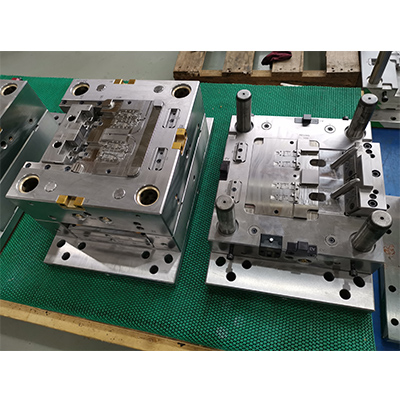

3 Plate Mould 49113-21

Mould Name: 3 plate mould

Part Material: PBT GF15

Product Size: ф34.9x82.29

Product Description: Mischschraube kpl

Mould Cavity: 2 Cavities

Mould Size: 250*230*350 MM

Mould Cavity Steel: 2343 ESR

Mould Injection System: 3-Plate point gate

Mould Ejection System: Round ejector

Mould Cycle Time: 28's

Mould Life Cycle: 500,000

Lead Time: 45 working days

Mould Features: insert molding

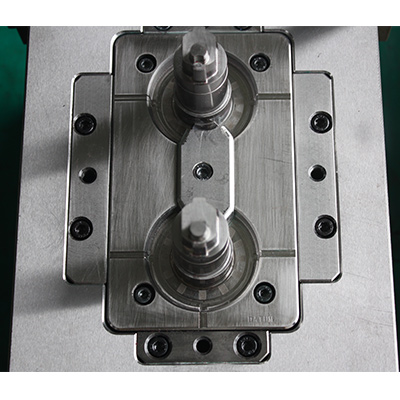

3 plate mould is also called pinpoint gate mould.

There are two parting surfaces to divide the mold into three parts. Compared with the two plate mould, the gate plate of three plate mold is added. It is suitable for the molds that do not allow gate marks around the product. This type of mold uses a pointed gate, so it is called pinpoint gate mold.

The typical 3 plastic plate mouldmovement process

The mold opening process: the three-plate mold has two parting processes, the first between the stripping plate and the cavity plate, and the second time between the cavity plate and the core plate. When the core side is pulled by the injection molding machine, as the A and B plate are equipped with a latch lock, and there is no connection or obstruction between the stripping plate and the A plate (in most cases, the pull rod is also equipped with a spring) At this time, the stripping plate is first separated from the cavity plate by the pulling force, and the cavity plate moves backward with the core plate. When moving to the set distance, it is blocked by the pull rod limiting block, because the A plate continues to move with the injection molding machine. Therefore, the pull rod is also driven, and the pull rod drives the stripping plate to move to the next set distance and then the pull rod and the cavity plate stops moving.

The injection molding machine continues to move backward, as the pulling force continues to increase, exceeding the locking force of the latch lock, the A plate is separated from the B plate, and stops when the set distance is reached.

The ejector plate drives the ejector mechanism (the ejector pin, the ejector rod, and the lifter) to start the ejection movement, and the finished product is ejected (automatically dropped or removed by the robot).

Clamping process - When there is a pullback mechanism on the ejector plate, the ejector plate is forcibly pulled back by the injection molding machine before clamping.

Under the push of the injection plastic moldingmachine, the core moves forward to the cavity side, if the ejector plate is not pulled back in advance, the return pin first contacts the cavity plate. Under the reaction force, the ejector plate is returned by the return pin.

The B plate is pressed against the A plate and the stripping plate, and finally completely tight. The nozzle on the injection molding machine is closely fitted with the nozzle bushing on the mold, and the next cycle of injection molding is started.

If you want to know more types of custom plastic molding china, please visit our website.

在线联系供应商

Other supplier products

| Plastic Insert Mold 139-86 | Mould Name: Plastic Insert Mold Part Material: PA + Glassfiber Product Size: 11*30*1.3 Product Description: Stator Mould Cavity: 4 Cavities Mo... | |

| Family Mould | HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold... | |

| Mold Trial | Plastic Mould Trialof Hankingtec In hanking mould’s trial shop, HanKing Mould Enginering Ltd.has7 injection molding machines with a clamping... | |

| Gear Mold | Custom Plastic Gear Injection Mold Making, with many different dimensions and material, 2 cavities or 4 cavities customized plastic gear mold. HanK... | |

| Insert Molding | What is medical insert molding? Insert molding toolingrefers to a molding process in which an integrated product is made by inserting a pre-prep... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |