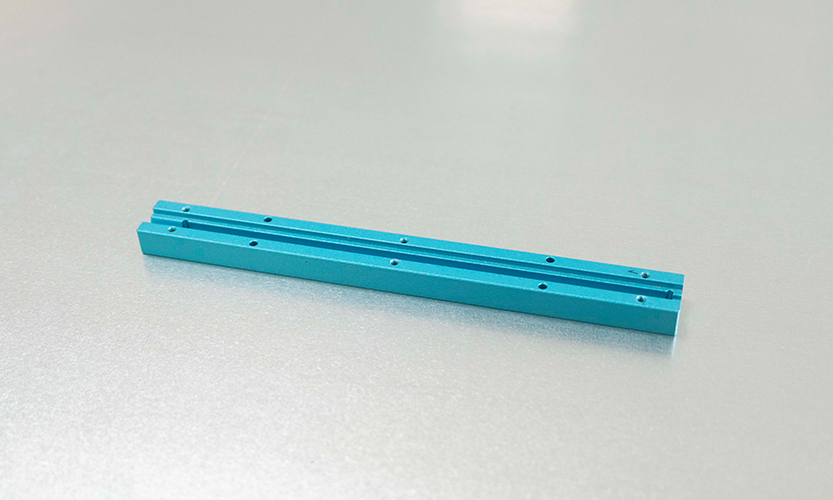

Custom Metal Machining Parts

Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more.

Our teams are able to manufacture metal machining parts via our precision manufacturing machine such as 3,4, and 5 axis CNC machining centers on 2D and 3D CAD drawing from the clients. Regardless of whether you are in search of precision plastic, CNC aluminum, stainless steel parts, our production lines are able to a wide range of precision plastic or metal machining parts.

Packson also provides a free quotation and discuss the most efficient and suitable machining process for your project. Don't hesitate to contact our team.

CNC Metal Machining Parts

We are able to manufacture plastic machining pieces with various plastic materials. POM, ABS, HDPE, Nylon, PLA, PC , PEEK , PMMA, PP, PTFE, etc. Full support different requirements of various surface treatments , tight tolerance.

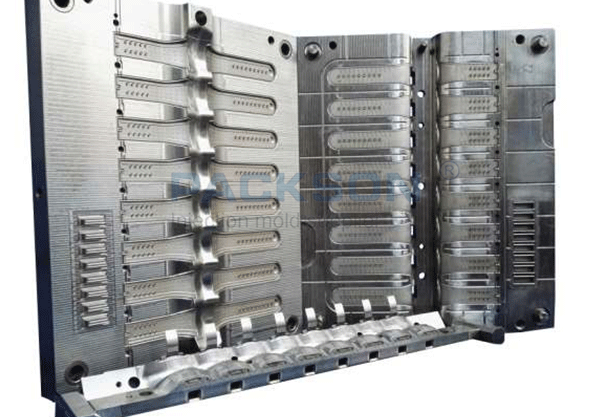

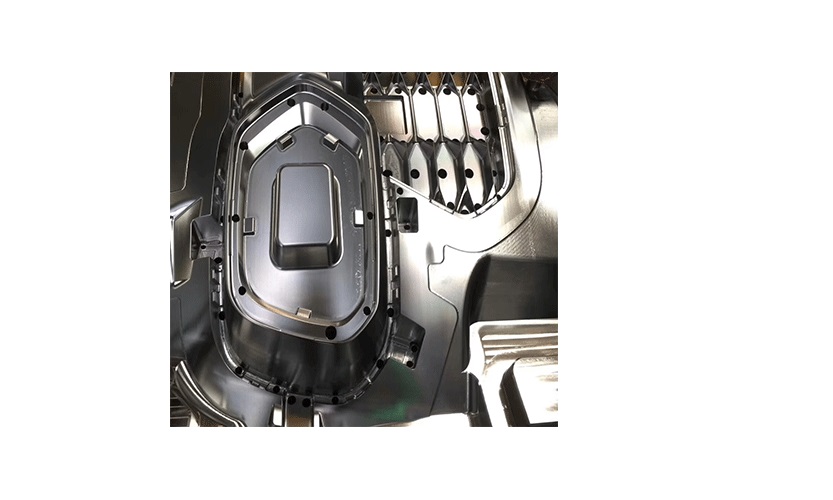

Mold Components

We are able to manufacture custom mold components(Mold slider, lifters, Mold inserts, Core and cavity, blocks, ejector pins) with high precision. With more than 10 years of experience working with European and American customers, we are familiar with different various standards and processes. Full support you to assemble components in your house.

Applications of steel machining parts

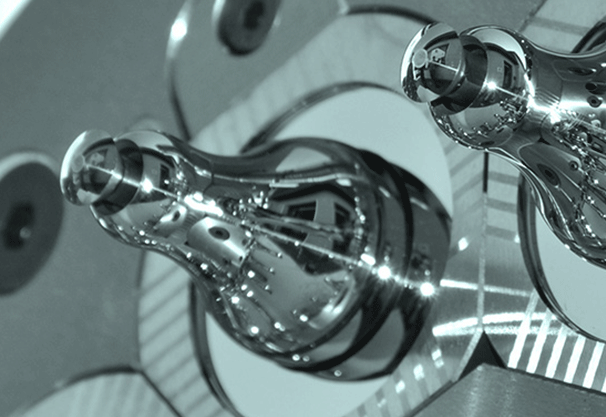

The prototype and production of CNC metal parts machining have been applied everywhere. It makes possible to create anything from the automotive industry to the medical field. This means we can characterize the applications of CNC machining in various fields.

Aircraft Fields:

The history of CNC machining is long-standing in the aerospace industry. Aircraft metal machining parts are processed with the greatest accuracy. This is vital for safety-sensitive applications. In addition, the CNC-compatible engineering metal line offers aerospace engineers many options. It is wide and reliable for the applications of CNC machining in the aerospace industry. Such as landing gear components, fuel flow components, engine mounts, and fuel access panels.

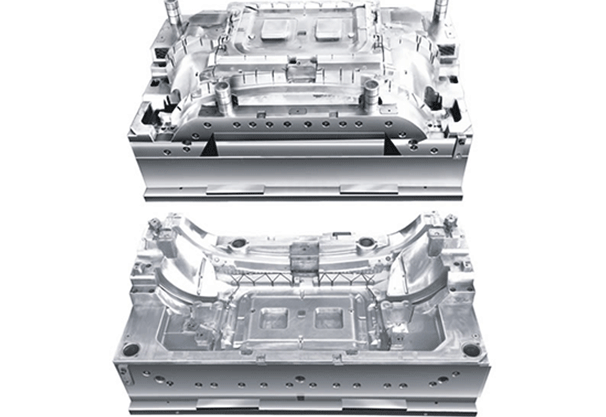

Automotive Fields:

The CNC milling machine is regularly used by the automotive industry in prototyping and production. The extruded metal can be machined into cylinder blocks, gearboxes, valves, spindles, and other components. In addition, plastic CNC machinery in components like instrument panels and gas gauges. In the automotive industry, CNC machining also helps in the creation of special metal machining parts. Different spare parts can also be created using CNC. This is due to the fact that processing times are quick and there is no minimum amount of parts required.

Healthcare fields:

CNC processing can be used on a variety of medical safety materials. As the process is adapted to single customized parts, it has numerous applications in the medical sector. Our precise machine guarantees tight tolerances. It is essential to the high performance and strict requirement of medical metal machining parts. Such as electronic enclosures, implants, orthotics, and surgical instruments.

Characteristics of Packson's stainless steel machining parts / stainless steel machined parts

Fast-Development:

Full-featured CNC design software and a qualified engineer make it possible to collect samples in 7 to 10 days.

Quick Quotation & Feedback:

From prototypes to final parts, we provide quick quotations and feedback with 1-24 hours for our clients.

Quality Control :

A complete set of inspection and quality control equipment makes great CNC machined products.

Massive Production Capacity :

Designing prototypes in wide fields and mass production of CNC metal machining parts.

Always On Time:

An accurate shipping process and a good warranty provider, we always deliver goods on time.

Advanced Equipments & Techniques:

With advanced CNC processing techniques ( Turning, Drilling, Milling) and precise equipment in Packson, we are able to produce a variety of metal machining parts with high precision.

Metal Machining Parts FAQ

Q

How much does it cost to have a part machined?

A

The cost of the CNC machine may vary considerably depending on what you are using it. You may also want to consider the following:

1. Specific costs related to your order.

2. The cost of running various types of machinery.

3. The cost of labor.

4. Any added cost of completion.

Q

How do you guarantee the quality of machined parts?

A

1. Tolerance abilities, Equipment capability, tools, and characteristics.

2. Personnel skills, training, and experience of the personnel.

3. Operating instructions for the use of the device.

4. Process control and record maintenance.

5. Quality measurements and certifications.

6. Follow-up of materials throughout the fabrication process.

7.Inspect points, procedures, and tools.

Q

How many types of machining process are there?

A

1.Milling 2. Drilling 3.Turning

Q

How can I reduce the cost of my machined parts?

A

Below is some basic information about each of these factors that can be used to eventually reduce the cost of CNC machining.

Rounded Internal Corners; Avoid Deep Pockets; Limit Use of Tight Tolerances; Expand Thin Walls; Limit the Length of Threads; Optimize Tapped Holes; Leverage; Standard Drill Sizes; Avoid Multiple Finishes; Split Up Complex Parts; Avoid Small Features with High Aspect Ratio; Order Larger Quantities.

Q

What parts can be machined?

A

CNC machining is well known for manufacturing various plastic or metal components in the automotive, engineering, medical, and aerospace industry. Such as aluminum components, steel components, brass components, acrylic components, and electronic components.

Q

How do I make custom metal parts?

A

1.Build your design 2. Complete and upload your design file 3. Select your material 4. Discuss the details 5. Wait for your shipment

As one of the most professional injection molding suppliers, Packson Mold provides custom molding services, custom aluminium parts,metal lathe components, machining small metal parts, machining abs,lsr silicone moldingand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| Silicone Rubber Mold | Silicone rubber is a kind of elastic material, which is widely used in industry and family. It has become an important part of our life. Meanwhile,... | |

| Clean Room Injection | With more than 20 years of experience in clean room injection molding, as the medical device injection moldingcompany in China, we specialize in va... | |

| Prototype Mold | Prototype molds are rapid processing for the molds. It's totally different from production molds as they can't be used in the long term. As a profe... | |

| Plastic Injection Molding | Packson's injection molding machines range in capacity from 60-800T, providing a wide range of options for our clients. Our facility includes 40 se... | |

| Custom Metal Machining Parts | Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more. Our t... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |