Vertical Centrifuge

The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including the blade), transmission, body, lubrication system, etc.

Application of Vertical Centrifuge Machine

The vertical centrifugeis fit for material dehydration, generally used for coal, salt and other materials. Our coal centrifuge has helped a lot of customers with their industrial projects.

Working Principle of Vertical Centrifuge Machine

Wet materials are feed into the mouth of centrifuge, then are accelerated by the rotated distribution cone and move rapidly towards the space between screen and rotor. With the centrifugal force, the smaller particles of material get closed to the screen surface, liquid and part of the particle size of less than 0.5 mm of material get across the material space and screen gap, then are thrown out of the screen, the larger particles of materials soon slipped into spiral nesting mouth along the screw blade with the action of gravity and centrifugal force fine material attached to the screen surface are discharged by the scraper centrifuge through blade action, while the liquid through the screen and fine materials are thrown into the water tank then outflow through the drain, so as to achieve a solid-liquid separation.

Technical Performance Parameters of Vertical Centrifuge Machine

|

Serial No. |

Part Name |

Numerical Value |

||

|

1 |

Feed size |

mm |

0~25 |

|

|

2 |

The screen cloth works area |

m2 |

||

|

3 |

Handling capacity per hour |

t/h |

140~200 |

|

|

4 |

The percentage of product water discharge |

% |

5~8 |

|

|

5 |

Strainer big end diameter |

mm |

1200 |

|

|

6 |

Strainer slit |

mm |

||

|

7 |

Main electrical machinery |

Model |

Y280S-4-V1 |

|

|

Power |

KW |

75 |

||

|

Rotating speed |

r/min |

1480 |

||

|

8 |

Lubricates the electrical machinery |

Model |

Y90L-4 |

|

|

Power |

KW |

|||

|

rotating Speed |

r/min |

1400 |

||

|

9 |

External dimensions Long × wide × high |

mm |

3160×2460×2680 |

|

|

10 |

Gross weight |

kg |

9121 |

|

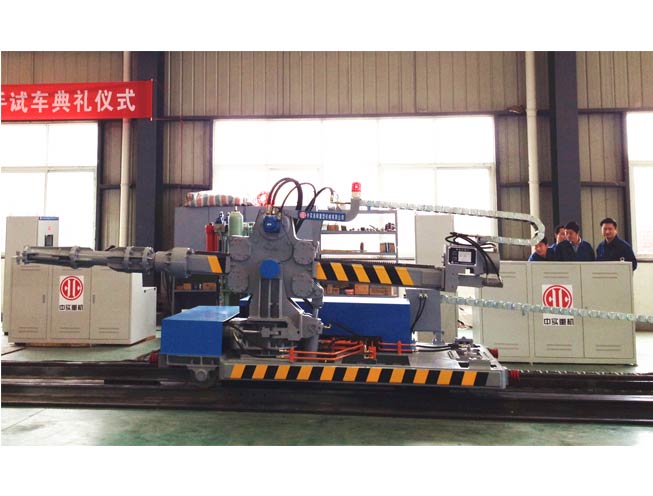

Installation and Testing of Vertical Centrifuge Machine

When the centrifuge is assembled completely in the manufactory, the test should be carried out in air operations. It should be sent out to the users in the form of machine after it is up to the requirements, the users can directly follow the steps to install the equipment when they get receipt of it.

1) Check whether the basis of surface is level, if it is uneven, adjust the leveling pad. Check the ground pin-hole size and pore size of the centre. Check whether the basis of elevation to meet the requirements.

2) Mount the shock absorber to the ground pin holes, install the nut first but not tightened until the machine is in the right place, then solid-tight.

3) Hoisting the machine in the place, tighten anchor bolts, tighten the upper pairs of nuts before the measurement with the caliper pad diameter, it is required that the diameter of compact size should be increased 2~3mm than the first fasten one.

1) Checked before testing items

2) Commissioning and inspection of the project

Meet the above requirements, follow these steps, and start running in the air for 8 hours.

- ℃.

3) Loading Test

When all functioning of the machine working in the air is normal, then gradually feeding at the same time pay attention to the functioning of the device, while there is no abnormal phenomenon, the handling capacity can be increased to 150~200t/h, the handling capacity of the material easily dehydrated can be larger, difficult to dehydration material handling capacity can be smaller. Add enough materials, it may take the measurement as the following items, when all meet the requirements, the equipment can be put into use.

Operation and Maintenance of Vertical Centrifuge Machine

1) Pre-drive checks

2) Driving

3) Parking

Centrifuge normal maintenance plays an important role in preventing accidents and injury in the weight of link components in the device’s using, and the systems should be required to perform.

1) Lined lid is easy to wear and tear, open the lid or observe the lid abrasion situation from the observation hole, if the abrasion is serious, it should be replaced promptly.

2) Distribution cone is mounted on the top of the rotor body, contacted with material directly and easy to wear and tear. Every time when you change the screen and scraper, pay attention to check the distribution of the remaining tapered wall thickness, if it is too thin, take replacement timely.

3) Screen is the key part of the centrifuge, it is forbidden that there is no wire, wood, bolts and debris in the machine while it is used. For a long time using, if a little screen surface was damage, it allowed to be repaired by welding, but if the gap in the screen is as large as 0.75 mm wear or screen seriously worn, the screen should be replaced. Likewise, if the mesh repair welding area is too large, re-do before the use of dynamic balance.

4) Spiral scraper, it should be paid attention to adjust the gap between blade and the screen surface when it is working, usually 0.3~1.5 mm. If the gap is too large, it can mount the adjustment pads on the top of the rotor body underside for each additional pad, the gap decreased 0.34 mm. If the adjustment of all cushion mount to the lower part, the gap remains large, replace the blade. It should pay attention to the pairs of containers while changing scraper, mount the weight of two scraper into a symmetrical position to keep the rotor body balancing performance. After replacement of the scraper, the machine should be conduct and test run in the air operation. If the rotor vibration is too large, it would have to do the rotor body balancing.

5)Export the protection lining, materials get through the lower scraper with the influence of centrifugal force, the material is left out in the protection of lining, and then fall until the belt exit cone machine, it should pay attention to the protection liner wear circumstances from the hole observed when it is used. When serious damage happened, replace it timely.

6) The export cone is at bottom of the machine, when material falls, the cone inner surface is often worn in use, and the lining should be checked regularly. If there is some damage, it must be promptly replaced.

7) The differential is a driving part of the machine, it should be aware of the lubrication conditions when it is used. It should pay attention to whether the oil is spilled, oil flow table is oil flow and the differential pulley-side and the upper part of bell-shaped cast-side sealing department have leaked oil. Enable that there is not any unusual noise in the working differential.

8) Lubrication system. It should be always checked the oil spill situation, pressure gauge and oil flow sheets. Oil filters in the filter and the oil tank strainer should be periodically cleaned or replaced. The oil level in the fuel tank must be within the upper and the lower limits shown in the table.

9) Cleaning the materials inside the machine regularly, rinsing the materials between the hood and lining surplus with red bell-shaped water, cleaning the appearance of the machines and the places around the equipment, make sure it is working in good condition.

As one of the most professional heavy equipment dealers, CIC provides auto drilling and tapping machine, tapping drilling machine, dry ball milland etc. Want to know more, contact us now.

在线联系供应商

Other supplier products

| Tube Mill | Tube Mill Tube mill is one of CIC grinding mill product series. The ball tube mill is mainly used for grinding finished products and raw materials... | |

| Metallurgical Furnace | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| Sludge Dryer Machine | Sludge DryerMachine CIC's sludge drying machine process was originally developed for the development of high viscosity media in the concentrating ... | |

| Vertical Centrifuge | The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including the blade), transmiss... | |

| Furnace Tapping Machine | We developed the discharge furnace robotic arm, based on the working process and tools of manual operation of slag port opening and closing of the ... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |