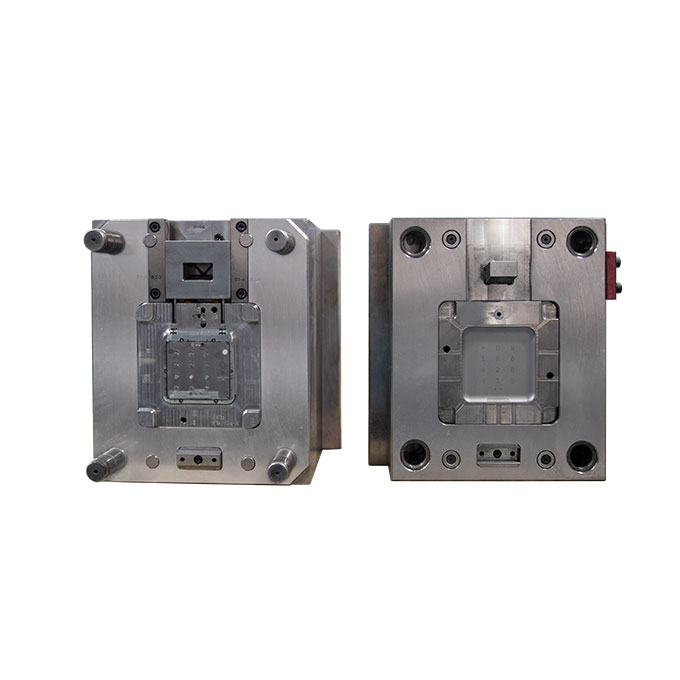

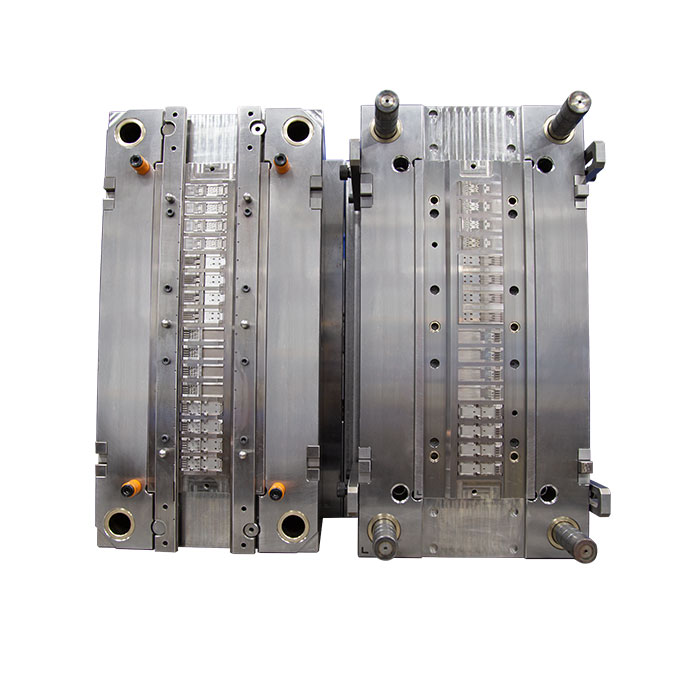

2K Mold

The rotary mold is composed of two-cavity and core sides, the two core sides are the same, only the cavity sides is different which the second color cavity is bigger than the first color, at the beginning of injection molding, the barrel of the two-color injection molding machine first injects the plastic into the mold cavity of the first color, after it is cured, the core side will be rotated after solid, then the first color part will be injected to the second color mold by core rotating, then the 2 shot moldbarrel will cover the first color part by injection, the two-cavity and core sides are continuously produced, then the part will be ejected out by the second color.

2k injection moldingdesign key points

- Generally speaking, the shrinkage rate of the two-color mold depends on the first color material, because the first color material has supported the outline of the plastic part, the second color material will not shrink more. As for how to determine the primary and secondary materials, there are many factors to be considered, such as the fluidity of raw materials, the shape of plastic products, and so on.

We also have types of 3k moldfor sale, more details, please visit our website.

As a plastic injection manufacturer, we can offer different kinds of plastic injection moldingfor customers, if you have interest, please leave us a message.

在线联系供应商

Other supplier products

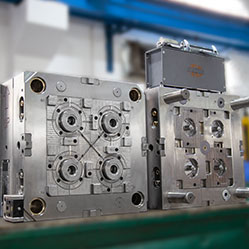

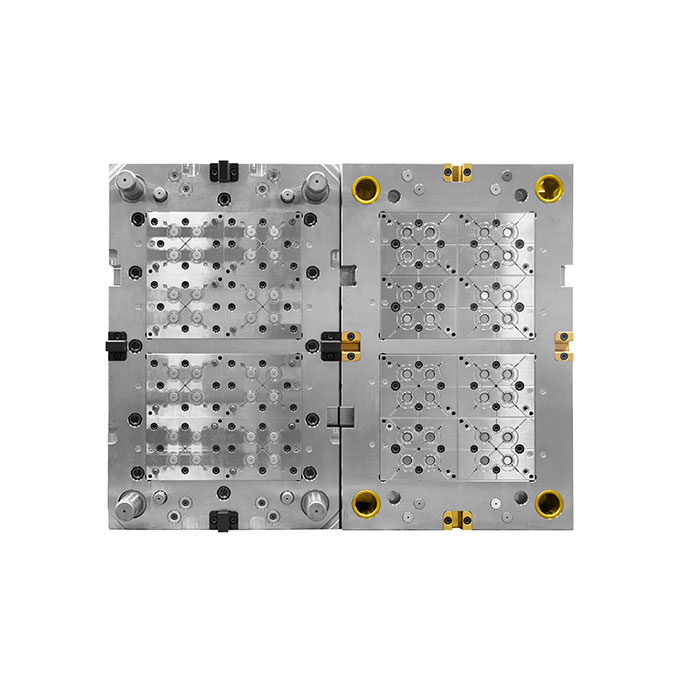

| Multi Cavity Mold | The runner filling balance must be considered when designing the multi-cavity mold in order to ensure the best effect of filling balance, the multi... | |

| Multi Cavity Medical Mold | Multi Cavity Medical Mold USM is an ISO9001:2015 certified plastic moulding servicesfactory, with over 15 years of professional experience and adv... | |

| Gas & Water Assisted Injection Mold | Gas Assist Injection Molding Design Guide Since the thermal conductivity and heat capacity of water are much bigger than nitrogen, so the inject... | |

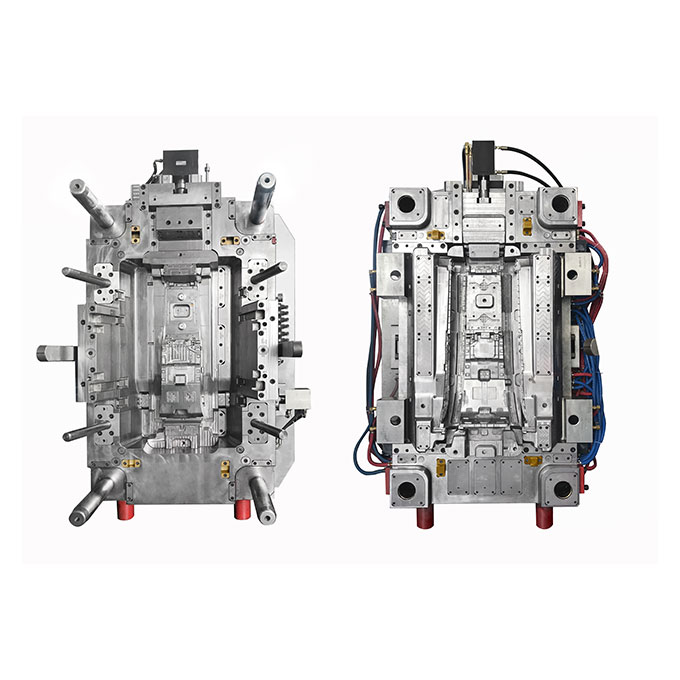

| Auto Parts Mould | Injection Moulding Automotive Partsfeatures: There are many undercuts on product inside and outside, and the undercut area is big too, the... | |

| Metal Insert Mold | Metal Insert Molding Choosing suitable material and molding conditions, not only for products that are easily deformed and damaged (such as glass,... |