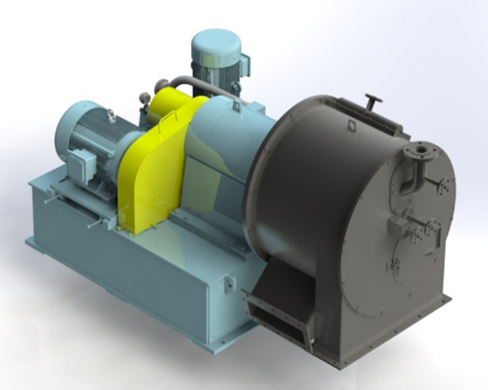

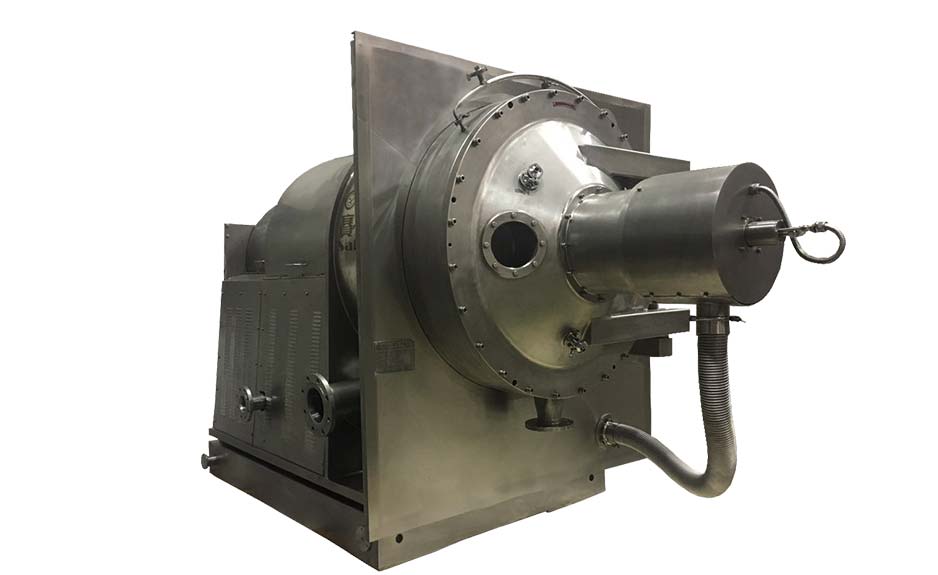

HR PISTONS PUSHING CENTRIFUGE

When the drum runs at a full speed driven by the main motor and transmission belt, the suspension of HR pistons pusher centrifuge machine will be led to the product distributing plate through the feeding pipeline continuously. Then the suspension will be distributed evenly on the filter net in the inner first-grade drum. Most of the liquid phase will be thrown out through the filter net and the filter holes on the drum wall, and then drained outside through the liquid outlet. The solid will be intercepted on the first-grade drum and form a cake ring.

HR PISTONS PUSHING CENTRIFUGE SPECIFICATION

HR Model and Main Parameters

Item/Model HR400-N HR500-N HR630-N HR800-N HR1000-N

Drum diameter (mm) inner/outer basket 337/400 410/500 560/630 720/800 920/1000

Length of filtering (mm) 160/160 180/180 240/240 300/300 240/320

inner/outer basket

Speed (r/min) 1500-2200 1200-2000 1000/1800 800-1600 650-1250

inner/outer basket

Separating factor (N) 503-1083 402-1118 352-1140 286-1145 236-875

inner/outer basket

Length stroke (mm) 40 50 50 50 50

Frequency of stroke (mm) 30-80 50-70 30-80 30-80 20-70

Main motor power (KW) 11 30-45 37-55 55-75 75-90

Oil pump motor Power(KW) 5.5 22 30 45 45

Production capacity (t/h) 1-8 5-15 8-25 15-40 18-50

Overall dimensions L×W×H (mm) 2460×1286 3590×1430 3500×1760 3700×1800 4200×1900

×1030 ×1642 ×1265 ×1450 ×1900

Weight (Kg) 2480 3500 4000 6000 12000

Pusher Centrifuge Working Principle

HR series centrifuge is a kind of horizontal two-stage pistons pushing centrifuge and filtering centrifuge with continuous operation. Materials are fed continuously through feeding pipe and distributed evenly on the inner drum wall under the full involving speed of both inner and outer drum. Under the centrifugal force, liquid will be drained outside through the filtering net and the filtering holes on the drum wall while the solid will be intercepted in the inner drum and form a cake ring. While the drums of the two grades are revolving together at a same speed, the inner drum will move reciprocately continuously in axial direction under the driven of the pistons,then the pushing plate will be able to push out the filter cake from the inner drum. In the next step, the filter cake will be pushed into the outer drum for further separation. Then the outer edge of the inner drum will push the new filter cake to the out of the outer drum continuously and then discharged through the scraping groove.

PUSHER CENTRIFUGE MACHINE FEATURES

All operations under full speed;Automatic operation with continuous discharging and great capacity. Crystal shape will be kept completely;Filter cake can be washed inside the machine; Product contact parts adopt stainless steel with good anti-corrosion property.

PUSHER CENTRIFUGE MACHINE APPLICATION

Two stage pistons pushing centrifuge usually used for separating even suspension with medium and coarse particles(>0.1mm) and high concentration(>30%). The bigger the particle, the higher the solid content, the higher the capacity and the better the separating effect.

Our company started to manufacture HR pistons pusher centrifuge pdfsince year 1965 with all models and more than 7000 sets output which has been widely used in chemical, fertilizer, salt, pharmacy and environment protection area.

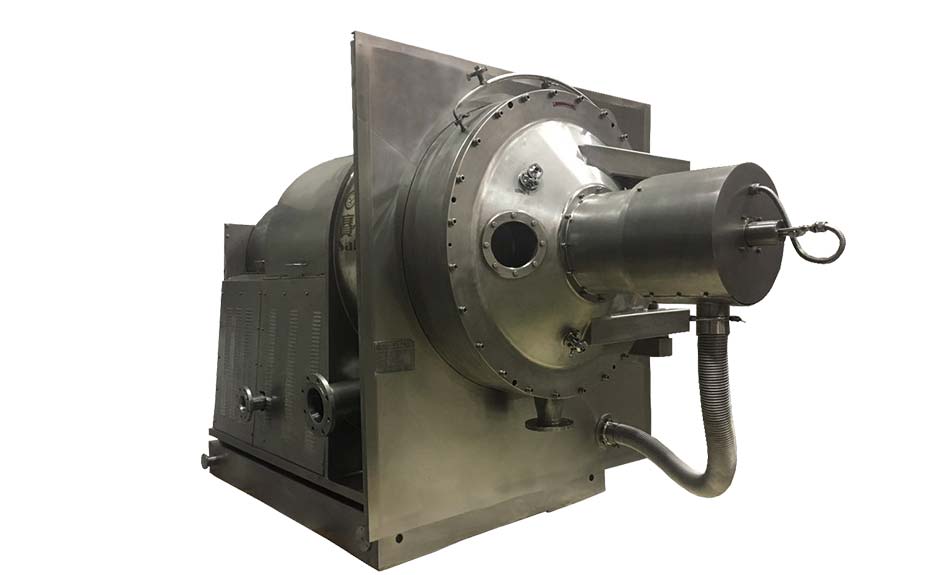

HR Using Scope

This pusher centrifuge type is well used to separate suspension with its solid size is over 0.1mm and density is over 30%. The pusher centrifuge machine can be used in the chemical, light, pharmacy and food industry to produce sodium chloride ammonium fluoride ammonium bicarbonate, sodium sulphate, urea, caffeine, polyethylene, polystyrene, oxalate, nitrate.

The choice of HR pistons pushing centrifuge:

HR Pistons Pushing Centrifuge Highlights

The pusher centrifuge machine can be operated continuously and steadily, which capacity is great.

Because of its high separating factor, types of pusher centrifuge can be dehydrated fully in the two drums. So the filter cake will contain less moist.

While there is a high demand to the purity of the products, the centrifuge can wash them and drain out the washing liquid and the mother liquid separately.

Low and even consumption of the power among the pusher centrifuge .

As a pusher centrifuge manufacturer, we can also provide types of centrifuge separator for sale, anything you need, please contact us.

在线联系供应商

Other supplier products

| INDUSTRIAL CENTRIFUGE MANUFACTURER | Saidelicentrifuge can be separated into lab centrifuge and industrial centrifuge machine with a larger model. And has been widely used in many indu... | |

| FSD CENTRIFUGAL DRYER | This industrial centrifugal dryerintegrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly su... | |

| INDUSTRIAL CENTRIFUGE MANUFACTURER | As one ofprofessional industrial centrifuge suppliers, Saideli provides high-quality lab centrifuge and centrifuge machine industrialwith a larger ... | |

| GKH AUTOMATIC SIPHON HORIZONTAL SCRAPER CENTRIFUGE | This screen centrifuge is controlled by PLC and regulates the speed by frequency convertor. The braking system of continuous centrifuge applies dyn... | |

| FSD CENTRIFUGAL DRYER | This centrifugal drying machineintegrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suit... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |