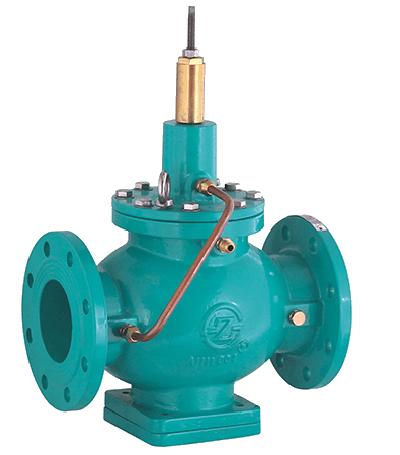

Modulating Float Valve

Features of modulating float control valve

Stable and reliable work, large flow;

Disc fast open and slow closed, no water hammer impact;

Good sealing effect and long service life;

Install at any location along with the height of the water tank and the working space.

Modulating Float Valve Working Principle

When the pipe supplies water from the inlet end, because the needle valve, ball valve, and float ball control valveare normally open, water enters the water tank through the micro-filter, needle valve, control room, ball valve, and float ball valve. At this time, there is no pressure in the control room; When the water level of the water tower rises to the set height, the ball float closes the ball float valve, controls the indoor water pressure rise, pushes the main valve to close, and the water supply to stop. When the water level drops, the float valve reopens, the water pressure in the control room drops, and the main valve opens again to continue the water supply, keeping the setting height of the liquid level.

Modulating Float Valve Installation and Commissioning

Horizontal installation is preferred for remote-controlled ball float valve. The main valve and ball float pilot valve can be remotely installed as a whole. This valve is installed in the water system and debugged. The globe valve is opened. The main valve needle valve is opened for 2 to 4 rounds. The ball valve is fully opened. For specific use, please consult ZecoValve Group.

Modulating Float Valve Material and Standard

Size Range: 2"~24"

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension :AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

|

Part |

Material |

Standard |

|

Body |

Ductile Iron |

EN 1563/DIN 1693 |

|

Bonnet |

Ductile Iron |

EN 1563/DIN 1693 |

|

Trim |

Stainless Steel 304 |

EN10088-1/ASTM A959 |

|

Seat |

Stainless Steel 304 |

EN10088-1/ASTM A959 |

|

Diaphragm |

EPDM / NBR |

ISO 4633 |

|

Pilot Valve |

Stainless Steel 304 |

EN10088-1/ASTM A959 |

|

For materials options not listed, consult factory. Zeco manufactures valves in more than 50 different alloys. |

||

在线联系供应商

Other supplier products

| 12 Inch Butterfly Valve | Description of 12 Inch ButterflyValve: Most of ZECO 12 inch butterfly valves operated by hand-wheel, wrench and handles, pay attention to the oper... | |

| Differential Pressure Control Valve | Festures of dpcv valve Accurate and stable pressure difference control; 20-250Kpa Pressure difference control range; Simple debugging, without c... | |

| Top Entry Ball Valve | Description Due to the distinctive nature of the environmental conditions and operating conditions of the process, a typical ball valve is not suf... | |

| Floating Ball Valve | Description of Floating Ball Valve: ZECO floating ball valve chinahas two seats supporting the ball Under medium pressure, the ball can be pressed... | |

| Gate Valve | ZECO is one of the professionalgate valve manufacturing companies, specializing in the production of wedge gate valve and through conduit gate valv... |