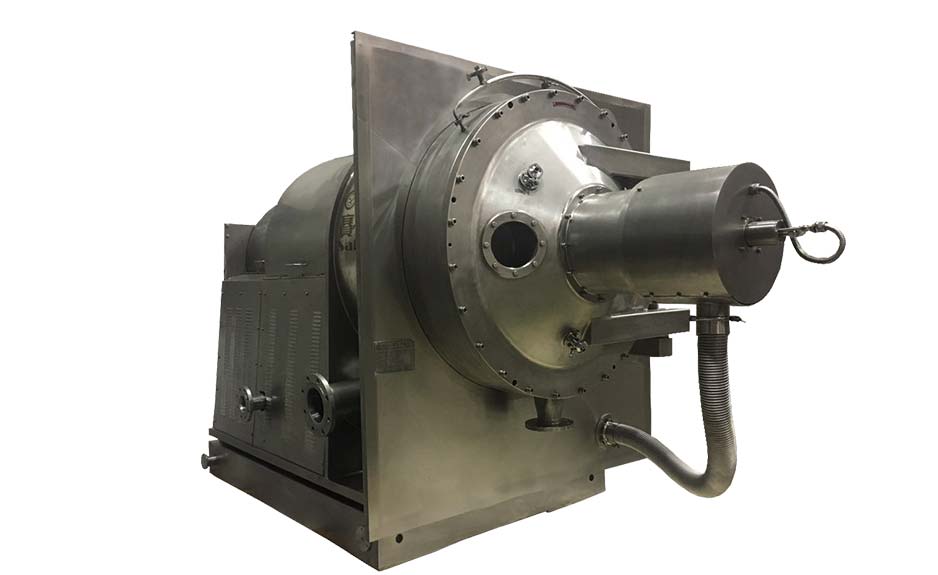

FW INVERTING CENTRIFUGE

When the drum is under high-speed operation, the suspension enters the drum through the feeding pipe. Under the action of centrifugal force, the suspension is evenly distributed in the filter cloth of the drum. The liquid phase passes through the pore of filter cloth, the gap of screen mesh, and the filter hole of the drum and then is discharged from the outlet of the mother liquid pipe; while the solid phase is intercepted to form a ring filter slag layer on the filter mesh. When discharging, the main engine of inverting centrifuge first slows down to the discharging speed, then starts the discharging motor and pushes the pusher out of the drum. Because the two ends of the filter cloth turn over, and the retained material is turned to the outside of the filter cloth.

FW INVERTING CENTRIFUGE SPECIFICATION

FW Main technical parameter

Item / Model FW-630 FW-800 FW-1000 FW-1300

Drum diameter (mm) 630 800 1000 1300

Drum volume (L) 70 120 200 350

Filter area (m2) 0.56 0.85 1.26 2

Max. revolving Speed (r/min) 1940 1600 1270 1000

Max. Separating factor (N) 1325 1144 901 726

Weight of Machine (Kg) 3600 4200 5500 6500

Outline Size (mm) (L×W×H) 2970×1040×1650 3980×1450×1890 4990×1650×2560 5900×2050×3250

FW INVERTING CENTRIFUGE CHARACTERISTICS

1. Fully sealed structure design, reliable sealing, no pollution to materials

2. The shell can be completed and turned over for easy cleaning and inspection.

3. Discharge without scraper mechanical parts, no damage to grain crystal.

4. There is no material residue in the filter cloth, which is convenient for the separation of materials in the next batch.

5. Unmanned operation, automatic detection, and operation.

FW INVERTING FILTER CENTRIFUGEWORKING PRINCIPLE

After the start-up of the equipment, firstly judge whether the proximity switch of the motor end is effective or not. If not effective, the assist motor will work to seal the drum. After that, the assist motor will stop and the main motor start to run. After the drum reaches the set speed, the feeding valve will open and suspension will enter into the full-speed rotary drum filtration through the feeding pipe. Under centrifugal force, the solid of the suspension will be distributed evenly on the internal surface of the filter mesh and most of the liquid will pass through the small holes on the filter mesh and drum wall and be drained outside through the liquid outlet. After a long time operation, the thickness of the solid product inside the drum will keep gaining. When reaching the set time, the feeding valve will close automatically. (feeding time will be changed for different products and can be adjusted at first commissioning).

FW Performance and Use

FW series are inverting filter centrifuges with intermittent feeding and intermittent discharging.

Feeding, separating, washing, dehydration, and other operating procedures are completed under full speed; discharging is completed under the condition of deceleration, which avoids material contact with subject other than equipment, and can protect the operator and material from pollution as well.

The machine meets GMP specifications and is suitable for filtration and separation in pharmaceutical, food, and chemical industries.

As a professional industrial centrifuge machine factory, Saideli provides industrial centrifugal dryer, solid solid separation equipment, industrial centrifuge machineand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| FSD CENTRIFUGAL DRYER | This drying centrifugemachine integrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suita... | |

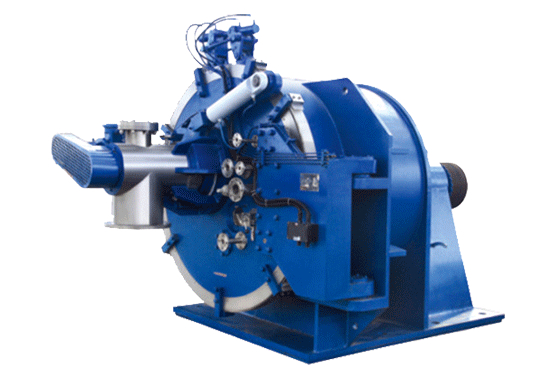

| GKC AUTOMATIC HORIZONTAL SCRAPER CENTRIFUGE | The perforated basket centrifugeis controlled by PLC. GKC automatic centrifuge adopts wall penetration installation; the power area and processing ... | |

| HR PISTONS PUSHING CENTRIFUGE | When the drum runs at a full speed driven by the main motor and transmission belt, the suspension of HR pistons pusher centrifuge will be led to th... | |

| GKH AUTOMATIC SIPHON HORIZONTAL SCRAPER CENTRIFUGE | This screen centrifuge is controlled by PLC and regulates the speed by frequency convertor. The braking system of continuous centrifuge applies dyn... | |

| SAIDELI-INDUSTRIAL CENTRIFUGE SEPARATOR MACHINE MANUFACTURER | Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial c... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |