EP-M450H Metal 3D Printer

With a building chamber size of 456*456*1080 mm³, Eplus3D Introduces EP-M450H to the successful line of MPBF 3d printing machine. The new EP-M450H is a marvelous metal printer that makes the production of reliable and high quality large metallic parts viable on industrial scale without requiring any tools.

EP-M450H Metal 3D Printer Features

EP-M450H Metal 3D Printer Feature High Quality

High Quality

Printed parts' density > 99.9 %, deviation in parts' mechanical properties < 5 %.

The optimized gas flow design ensures efficient removal of smoke and splashes as well as achievement of uniform and consistent full size printing.

Dynamic software with ability to divide the model into different sections like upper and lower surfaces, core areas and small areas etc. Different process parameters can be applied individually to these parts for high printed part quality.

Repeatable positional accuracy along Z-axis of building direction ≤±5 μm.

Overlapping deviation with dual laser printing ≤±0.1 mm. Overall mechanical properties of the printed part remains same when compared to printing results with the single laser machine.

EP-M450H Metal 3D Printer Feature High Efficiency

High Efficiency

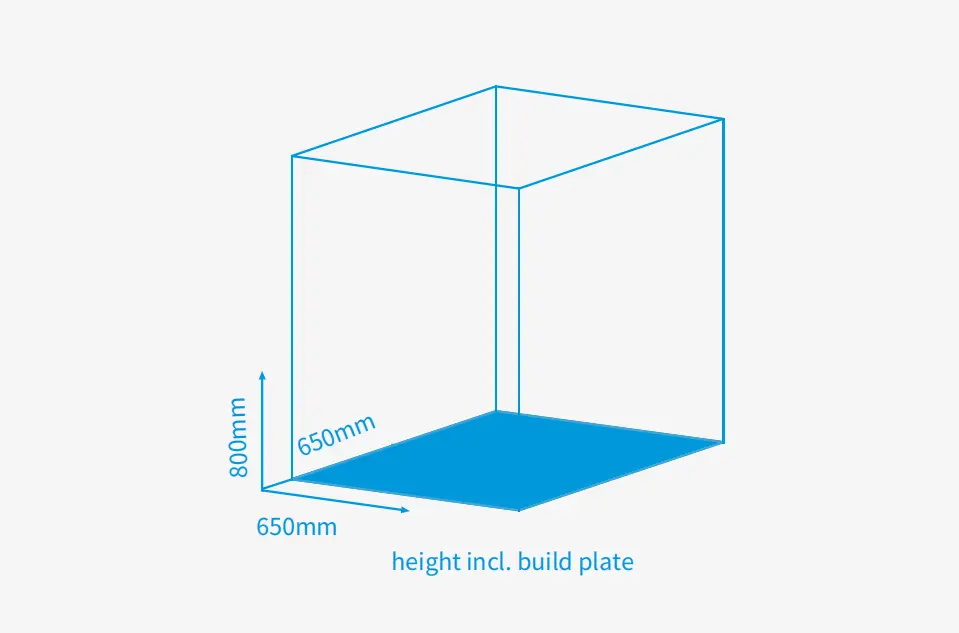

Build chamber size (X*Y*Z): 456*456*1080 mm³, build chamber volume >200 L.

Printing with increased layer thickness can be realized, increasing the production capacity.

With in-house developed processing software (EP-Hatch), optimized scanning strategies can be achieved yielding reduced print duration.

Optional dual laser system with 2*500 W fiber lasers increases printing efficiency by 70 %.

Maxiumum building rate of 55 cm³/h.

Bi-directional powder re-coating method leads to reduced re-coating time.

EP-M450H Metal 3D Printer Feature Reliable

Reliable

Excellent core optic components from world-class supplier and mature process control parameter algorithm provides highest part quality.

High quality uniform part printing due to excellent control over building environment and components.

Tightly sealed build chamber maintains oxygen concentration <100 ppm and a stable pressure during printing.

Sustained monitoring of powder left in feeder and ability to add powder without stopping the machine ensures uninterrupted part printing.

Double protection of chamber door is attained due to dual gas releasing ports on top of printing chamber.

EP-M450H Metal 3D Printer Feature Cost-effective & Easy Operation

Cost-effective & Easy Operation

Blow back enabled coarse and fine filtration system ensures prolonged lifetime of filter over 1000 hrs.

Highly user friendly software interface and one-click printing technology makes printing super simplified.

Comparability with different types of recoater blades such as ceramic, PU, alloy steel etc.

Reduced gas consumption during printing ≤6 L/min helps reducing operation cost.

Traceable print records after every print and real-time display of readings for various sensors.

EP-M450H Metal 3D Printer Open System

Open System

Open parameters for editing laser power, scan speed, scan direction, up and down facing surfaces etc.

Open system ensures freedom to choose among wide range of metal powders available in market.

Process software can be integrated with Siemens NX software to realize effective planning of design, simulation and printing path planning, within one software and highly improving the production efficiency.

Process software supports SLC and CLI formats.

What can EP-M450H print?

Exhaust Nozzle Exit

Machine: EP-M450H

Process: Metal Powder Bed Fusion (MPBF)

Material: TC4

Size: Φ394x341mm³

Printing time: 150 h

Application: Aerospace

Technical Specifications

|

Machine Model |

EP-M450H |

|

Build Chamber (XxYxZ) |

456*456*1080 mm³ |

|

Optical System |

Fiber Laser 500W/1000W (single or dual-laser optional) |

|

Spot Size |

90-130µm |

|

Max Scan Speed |

8m/s |

|

Layer Thickness |

20-120µm |

|

Building Speed |

Single Laser: 15~35cm³/hDual Laser: 35~65cm³/h |

|

Material |

Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

|

Power Supply |

380V, 10kW, 46.4A, 50 / 60Hz (Dual Laser: 13kW, 50A) |

|

Gas Supply |

Ar/N₂ |

|

Forming chamber oxygen content |

≤100ppm |

|

Dimension (WxDxH) |

6410*3670*4850mm³ |

|

Weight |

15000kg |

|

Software |

EPLUS 3D, EPHatch |

|

Input Data Format |

STL file or other convertible format |

As one of the professional 3d printing machine manufacturers, we provide additive manufacturing metal 3d printing, sls 3d printer for sale, additive manufacturing, resin 3d printer for sale, etc. For more information, please feel free to contact us!

在线联系供应商

Other supplier products

| EP-M450H Metal 3D Printer | With a building chamber size of 456*456*1080 mm³, Eplus3D Introduces EP-M450H to the successful line of MPBF 3d printing machine. The new EP-M... | |

| Additive Manufacturing Machine in Aerospace & Aviation | Aerospace & Aviation Like a bright pearl in the crown of modern industry, the development of Aerospace Science and Technology directly reflect... | |

| Eplus3D EP-A650 Resin 3D Printer | EP-A6503D Printer Stereo Lithography is developed by Eplus3D, which is professional in 3D printing technology. The system is user-friendly with hig... | |

| EP-M650 Metal 3D Printer | EP-M6503DMetal Printer Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 650 x 650 x 800 mm build envelope and four laser ... | |

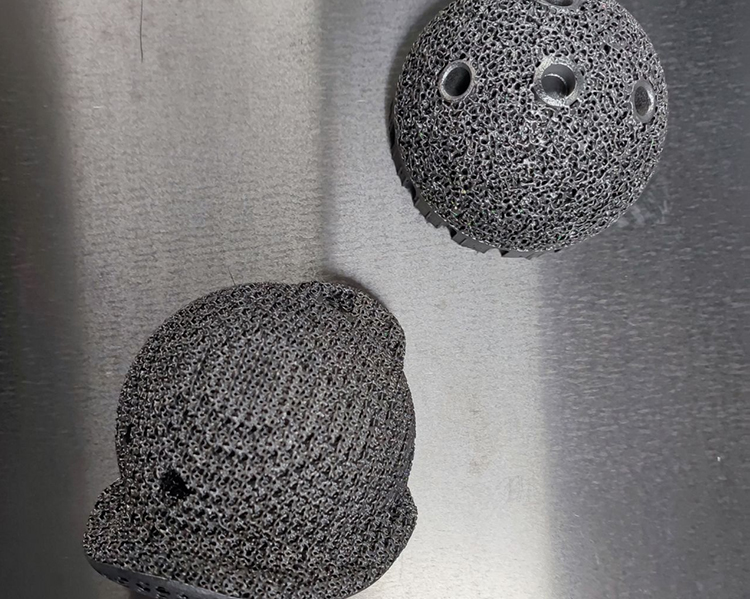

| Additive Manufacturing Machine in Healthcare | Healthcare In modern medicine, more artificial prosthesis, such as bone joint, bone repair and heart valve, are implanted into the human body to r... |

Same products

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Potassium Dihydrogen Phosphate (MKP) | 卖方: Hebei Lvwang Ecological Fertilizer Co., Ltd. | Potassium Dihydrogen Phosphate (MKP) Potassium dihydrogen phosphate(MKP) is an efficient phospho... |