Exploring the Art and Science of Plastic Basket Mould Manufacturing

today's fast-paced world, where convenience and efficiency are paramount, plastic baskets have become an integral part of our daily lives. These versatile containers serve a multitude of purposes, from carrying groceries to organizing household items. Behind the seamless production of these ubiquitous plastic baskets lies a fascinating world of craftsmanship, technology, and innovation: plastic basket mould manufacturing.

This article embarks on a comprehensive journey into the realm of plastic basket moulds, unraveling the intricacies involved in their design, production, and application. From the raw materials used to the cutting-edge techniques employed, we delve deep into the art and science that make these moulds an indispensable component of modern manufacturing processes.

The Anatomy of a Plastic Basket Mould

The foundation of any plastic mould lies in the choice of materials. The durability, heat resistance, and cost-effectiveness of the mould depend on the material selection. In the case of plastic basket moulds, high-quality steels like P20, 718, and S136 are commonly used. These materials exhibit excellent wear resistance and longevity, essential for high-volume production.The design of a plastic basket mould is a crucial step that determines the final product's quality. Mould designers meticulously plan the cavity and core shapes, gating systems, and cooling channels to ensure the plastic flows evenly and solidifies without defects. Advanced CAD and simulation software have revolutionized the design process, allowing for precise customization and optimization.

Manufacturing Techniques

Computer Numerical Control (CNC) machining plays a pivotal role in creating the intricate features of plastic basket moulds. CNC machines are used to mill, drill, and shape the mould's components with remarkable precision. This step is critical in achieving the desired geometry and functionality of the mould.EDM is another indispensable technique used in mould manufacturing. It employs electrical discharges to erode metal and create complex shapes. EDM is especially useful for producing fine details, intricate textures, and tight tolerances in mould components.Heat treatment is crucial to enhance the hardness and durability of mould components. Processes like hardening and tempering ensure that the mould can withstand the stress and wear of repetitive use, extending its lifespan.

Injection Moulding Process

The design of the gating system, which controls how molten plastic enters the mould cavity, is a critical aspect of plastic basket mould manufacturing. Proper gating ensures even filling and minimizes defects like warping and shrinkage.Effective cooling is essential to ensure rapid and uniform solidification of the plastic. Cooling channels strategically embedded within the mould help maintain consistent temperature distribution, preventing defects and reducing cycle times.

在线联系供应商

Other supplier products

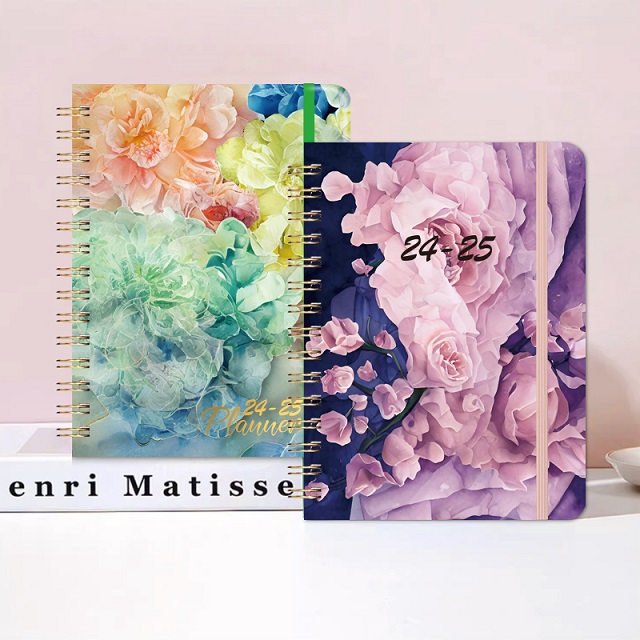

| Daily Planner Spiral Notebook | 便携式日程表 A5 每日计划螺旋笔记本是一款多功能笔记本,旨在帮助个人保持井然有序并管理日常日程。这款小巧的笔记本尺寸完美,为 A5 格式,便于携带,在任何环境下使用都很方便。 < > > | |

| Exploring the Art and Science of Plastic Basket Mould Manufacturing | today's fast-paced world, where convenience and efficiency are paramount, plastic baskets have become an integral part of our daily lives. These v... | |

| Shaved Ice Machines | of Shaved Ice Machines:Versatility in Flavor Options: Shaved ice machines allow you to with a wide range of flavors, offering a refreshing treat t... | |

| Manual Farm Sprayer | Our Manual Farm Sprayer is designed with the user in mind. The ergonomic handle and lightweight frame make it comfortable to use, even during long ... | |

| Timing Belt | Our Transmission PU Open Timing Belts are made from premium polyurethane, a material chosen for its exceptional strength, flexibility, and resistan... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |