CA Series-550CA30 PEEK Carbon Fiber Reinforcement

CA Series-550CA30peek carbon fiberreinforcement is a 30% carbon fiber reinforced naturalPEEK material, the addition of carbon fiber significantly increased the material's wear resistance and high temperature mechanical strength, thermal conductivity is pure resin G series 3 times.

Specification of CA Series-550CA30 PEEK withCarbon FiberReinforcement

|

Material Properties |

Test Method |

Conditions |

Units |

770G |

|

Mechanical Data |

||||

|

Tensile Strength |

ISO 527 |

B reak,23℃ |

MPa |

- |

|

Y ield,23℃ |

MPa |

100 |

||

|

Tensile Elogation |

ISO 527 |

Break,23℃ |

% |

45 |

|

Flexural Strength |

ISO 178 |

Break,23℃ |

MPa |

- |

|

Y ield,23℃ |

MPa |

165 |

||

|

Fleoural Modulus |

ISO 178 |

23℃ |

Gpa |

|

|

Compressive Strength |

ISO 604 |

23℃ |

MPa |

125 |

|

Charpy Impact Strength |

ISO 179/leA |

Notched |

kJm-2 |

7 |

|

ISO 179/IU |

Unnotched |

kJm-2 |

- |

|

|

Izod Impact Strength |

ISO 180/A |

Notched |

kJm-2 |

|

|

ISO 180/U |

Unnotched |

kJm-2 |

- |

|

|

Mould Shrinkage |

ISO 294-4 |

Along flow |

% |

1 |

|

Across flow |

% |

|||

|

Thermal Data |

||||

|

Melting Point |

ISO 11357 |

℃ |

343 |

|

|

Glass Tansition (Tg) |

ISO 11357 |

Onset |

℃ |

143 |

|

Special Heat Capacity |

DSC |

23℃ |

kj kg-1℃-1 |

|

|

Coefficient of Thermal Expansion |

ISO 11359 |

Along flow below Tg |

ppm K-1 |

45 |

|

Along flow above Tg |

ppm K-1 |

120 |

||

|

Heat Deflecion Temperature |

ISO 75A-f |

℃ |

152 |

|

|

Thermal Conductivity |

ASTM C177 |

23℃ |

W m-1K-1 |

|

|

Flow |

||||

|

MeltIndex |

ISO 1133 |

380℃,5kg |

g10min-1 |

10 |

|

Miscellaneous |

||||

|

Density |

ISO 1186 |

Crystalline |

gcm-3 |

|

|

Amorphous |

gcm-3 |

|||

|

Shore D Hardness |

ISO 868 |

23℃ |

85 |

|

|

Water Absorption(3.2mm thick Tensile Bar) |

ISO 62-1 |

24h,23℃ |

% |

|

|

by immersion |

Equilib riu m,23℃ |

% |

||

|

Electrical Data |

||||

|

Dielectric Strength |

IEC 60243-1 |

2mm |

kV mm-1 |

23 |

|

Comparative Tracking Index |

IEC 60112 |

V |

150 |

|

|

Dielectric Constant |

IEC 60250 |

23℃,1kHz |

||

|

23℃,50kHz |

3 |

|||

|

Loss Tangent |

IEC 60250 |

23℃,1MHz |

||

|

Volume Resistivity |

IEC 60093 |

23℃,1V |

Ω cm |

10 16 |

|

275℃ |

Ω cm |

10 9 |

||

More kinds of peek composite material, please visit our website.

在线联系供应商

Other supplier products

| Grade GL Glass Filled Fiber Reinforced PEEK | PEEK-GL series, is a glass fiber composite modified PEEK glassmaterials, currently available from 5% -35% of different mass fractions of reinforced... | |

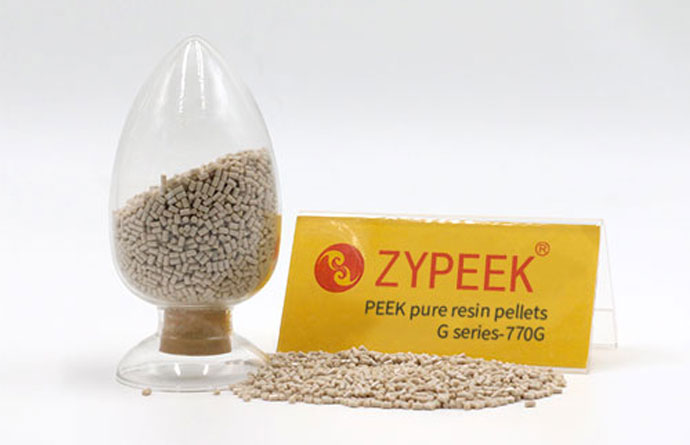

| ZYPEEK PEEK Raw Materials | PEEK polymer raw material is a kind of semicrystalline aromatic polvmer and its main chain of macromole is consist of arvl. ketone, and ether. PEEK... | |

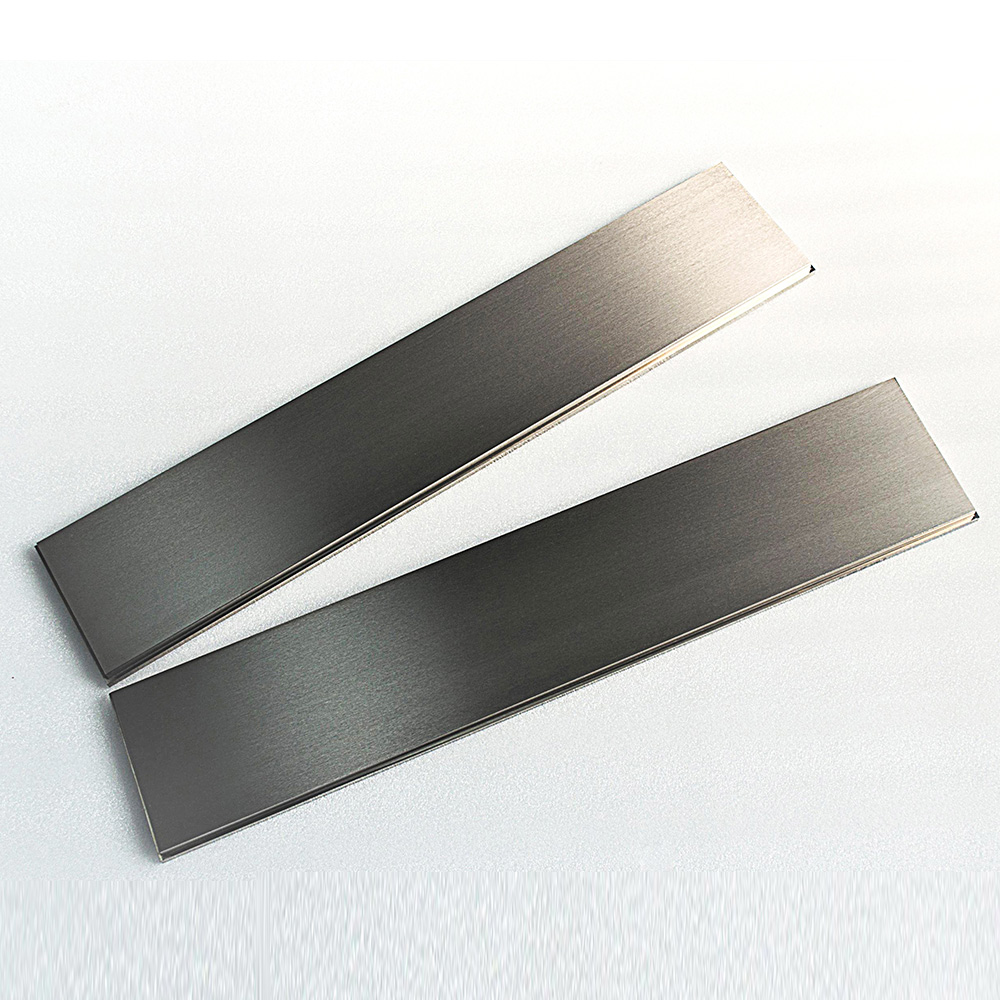

| Compression Molding Peek | Compression Molding PEEK PEEK has excellent corrosion resistance, radiation resistance, high-temperature resistance, low-temperature resistance,... | |

| Peek Materials Applications | Peek Material Applications Natural peek materialhas excellent comprehensive properties and can replace traditional materials such as metals and ... | |

| PEEK in Electronic & Electrical | PEEK is a C-level insulating material, keeps excellent insulating properties under high temperature, high pressure, high humidity and other environ... |

Same products

| Potable Water Storage Tank | 卖方: 854818 | Potable Water Storage Tank In strict accordance with the content of the international water safet... | |

| Nozzle Sprayer DLLZ157P964 | 卖方: China lutong | Nozzle Sprayer DLLZ157P964 Nozzle Sprayer DLLA148P2382+Chris Whats/ app:+8–6–1&ndash... | |

| luminous pigmen ment | 卖方: 成飞经理,15813639200:李老师 后面华兴玻璃厂 ,高速大丰田阿波罗 集美天成 | ``Dan qin cha ban sheng`` if hears`s so you love. | |

| titanium sputtering targets | 卖方: 0000 | titanium sputtering targets Titanium used in a wide variety of products such as watches, dr... | |

| Volvo Articulated Dump Truck Parts | 卖方: XINGTAI ME MINING EQUIPMENT CO.,LTD. | Volvo Articulated Dump Truck Parts VOLVO Dump Truck Spare Parts XTME offers a professiona... |