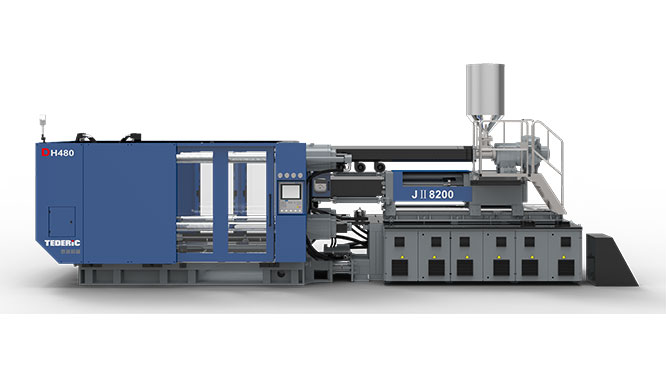

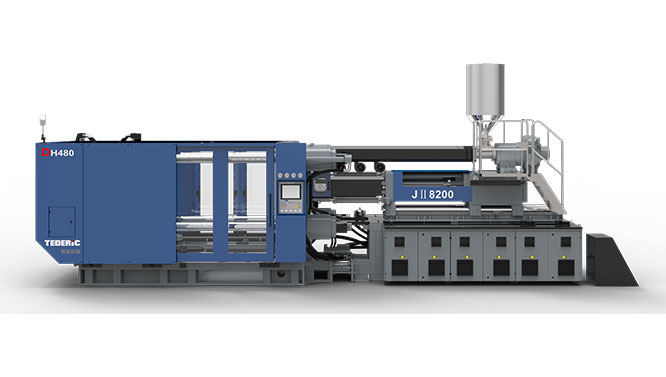

DT-i Servo Energy-saving Injection Molding Machine

Introduction

DT-i servo energy saving injection molding machineis basically the High rigidity double elbow five hinge clamping mechanism, equipped with balanced moving dual-cylinder and injection unit. After dozen years of R&D, improvement and accumulation of manufacturing experiences, this series has acquired great trust and admiral from domestic and overseas clients by its advanced design concept and reliable parts configuration. The clamping force of DT-i servo injection moulding machine range from 1000KN to 40000 KN, and injection size from 168cm³ to 67906cm³. DT-i IMM machine is a hydraulic plastic molding machinethat employs hydraulic cylinders to clamp together two halves of a mold at high pressure. Plastic substrate pellets are then melted, and the liquid is injected into the mold cavity. Once the plastic has cooled and hardened, the mold halves are separated, the part is extracted, and the process is repeated. Hydraulic molding is a popular choice for the automotive industry, which requires the production of large, heavy parts such as bumpers. Compared with electric machines, the hydraulic double injection moulding machinehas greater clamp force for large parts, better injection rates and ejection capability. Tederic is a top hydraulic moulding machine manufacturer in China, who offers various hydraulic imm machines including DT-i, DT-M(F), DT-JI, DT-JII, DH-i series, etc.

Design Highlights:

Flexble Design

Modularized design, to provide customers with wider choice on machine dimension.

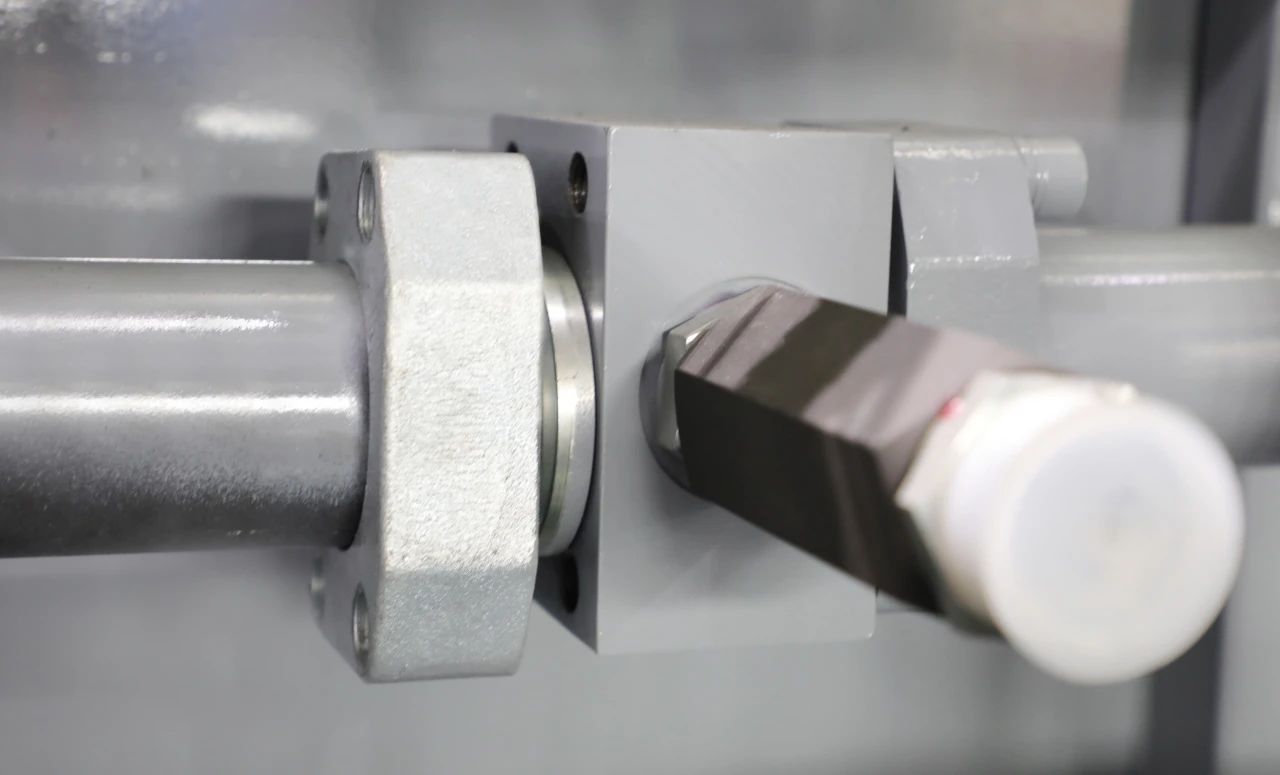

Reduced Oil Leakage

Feature:

High molding precision: injection weight repeatability precision is up to 0.3%

High repeat position precision: repeatability precision of mold opening and injection position within ± 0.5 mm.

Energy saving injection machinewholescheme: deploying of high-efficiency parts and energy saving-oriented design on mechatronics system.

Leading servo dynamic system: 30ms response, and to save 30%~80% energy compared to the traditional hydraulic system.

Tederic Machinery Co., LTDoperates as an world-renowned plastic injection molding machine manufacturer and solutions provider. The company is renowned amongst customers for its excellent product performance , satisfactory technical support and after sales service.

Tederic injectionwas founded in 2003, having two main factories in China currently,one is Tederic headquarters and one is Tederic Heavy machinery factory, which are located in Hangzhou City and Huzhou City respectively. The total plant area are 120,000 square meters and the total number of employees is more than 800. We praise the concept of innovation and implements which by spirit of improving every day. After 16 years of continuous development and putting efforts, Tederic has become one of the top three enterprises in China's injection molding machine industry in terms of comprehensive strength. In 2017, Tederic machinery co., LTD was listed on the main board of the Shanghai stock exchange (SH603289), and it is also the first injection molding machine company listed on the main board of China.

在线联系供应商

Other supplier products

| DH-JII Two-platen Medium to High Pressure Dual-stage Injection Molding Machine | Introduction DH-JII all hydraulic injection molding machine series is of two-platen clamping unit, equipped with injection unit of large injection ... | |

| DH-JII Two-platen Medium to High Pressure Dual-stage Injection Molding Machine | Introduction DH-JII all hydraulic injection molding machine series is of two-platen clamping unit, equipped with injection unit of large injection ... | |

| DE-E All-electric Injection Molding Machine | Introduction DE-E series is TEDERIC's high performance all electric molding machines. The whole machine applies components of internationally renow... | |

| DE-E All-electric Injection Molding Machine | Introduction DE-E series is TEDERIC's high performance all imm injection moulding machine. The whole machine applies components of internationally ... | |

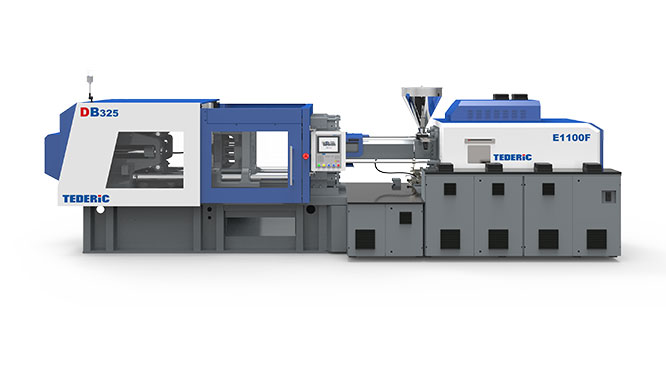

| DB-EF Electric Hybrid Injection Molding Machine | Introduction This is an hydraulic-electric hybrid injection moulding machine, with the characteristics of hydraulic mold closing and electric inj... |