HMC-S HORIZONTAL MACHINING CENTER WITH PALLET CHANGER

DEED horizontal machining center with pallet changer mainly used for the processing of box, shell, and special-shaped parts in automobiles, motorcycles, especially auto engine shell, reducer shell, mold, and general machinery industries. Our horizontal machining center for sale is at a good price. Contact us now!

HMC80S HMC-S HORIZONTAL MACHINING CENTER WITH PALLET CHANGER VIDEO

HMC-S HORIZONTAL MACHINING CENTER WITH PALLET CHANGER SPECIFICATION

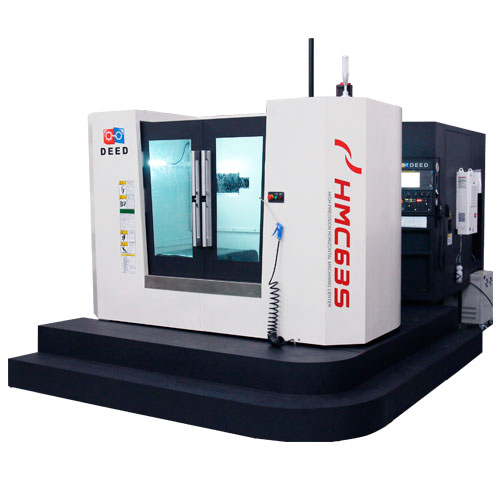

HMC63S horizontal machining center with pallet changer

TRAVEL

X-axis travel 1050mm

Y-axis travel 800mm

Z-axis travel 950mm

Spindle center to table surface 120~920 mm

Spindle nose to table surface center 200~1150 mm

Maximum workpiece height 1050mm

Maximum workpiece diameter 1000mm

SPINDLE

Drive type Belt drive

Spindle taper BT50

Max. Speed 6000 rpm

Spindle Power 15/18.5 kW

Spindle Torque 143/236 Nm

TABLE

Size 630x630mm

Max load 1200kgs

No. of table 1

Minimum scale degree 1°

FEED

Max. cutting speed 0-10000 mm/min

Rapid traverse 24/24/24 m/min

ACCURACY

X/Y/Z Axis Positioning 0.01mm

X/Y/Z Axis Repeatability 0.006mm

B Axis Positioning 10"

B Axis Repeatability 3"

ATC

Type Disc type ATC 24T

Maximum tool size(full/unfull/length) Φ112/Φ200/350

Maximum tool weight 15kg

Min. Time of Tool Change 7s

HMC80S horizontal machining center with pallet changer

TRAVEL

X-axis travel 1500mm

Y-axis travel 1000mm

Z-axis travel 1150mm

Spindle center to the table surface 120~1120 mm

Spindle nose to table surface center 250~1400 mm

Maximum workpiece height 1200mm

Maximum workpiece diameter 2300mm

SPINDLE

Drive type Belt drive

Spindle taper BT50

Max. Speed 6000 rpm

Spindle Power 15/18.5 kW

Spindle Torque 143/236 Nm

TABLE

Size 800x800mm

Max load 2500kgs

No. of table 1

Minimum scale degree 1°

FEED

Max.cutting speed 0-10000 mm/min

Rapid traverse 24/24/24 m/min

ACCURACY

X/Y/Z Axis Positioning 0.015mm

X/Y/Z Axis Repeatability 0.008mm

B Axis Positioning 10″

B Axis Repeatability 3″

ATC

Type Disc type ATC 24T

Maximum tool size(full/unfull/length) Φ112/Φ200/350

Maximum tool weight 15kg

Min. Time of Tool Change 7s

OTHERS

Air Pressure 0.65Mpa

Power supply 380V/50Hz

Machine weight 15500kgs

Machine Floor Space (L *W *H) 6600×4700×3400mm

Most Required CNC Machines

5 axis gantry type machining center

Horizontal boring and milling center

CNC drill tap machine

CNC horizontal turning center

planer type horizontal boring machine

Technology Upgrade of horizontal machining center with pallet changer

Deed CNC introduces its cutting-edge horizontal machining center with pallet changer, revolutionizing manufacturing efficiency. This innovative system markedly enhances production capabilities by allowing simultaneous machining on one pallet while loading and unloading workpieces on another. This intelligent design minimizes machine downtime and optimizes the machining center's throughput.

The pallet changer system plays a pivotal role in elevating production efficiency. By facilitating seamless workpiece pre-loading and unloading during the machining process, it mitigates the need for manual intervention, thereby reducing the risks associated with human errors. Moreover, this automation significantly contributes to the reduction of part processing cycle times, amplifying overall productivity.

The benefits extend further, as the pallet changer system also empowers the horizontal machining center with pallet changer with heightened adaptability. It accommodates a diverse range of workpiece types and sizes, fostering a greater degree of production versatility. This adaptability not only streamlines the transition between different tasks but also optimizes the use of the machining center's capabilities.

Embracing Deed CNC's horizontal machining center with pallet changer represents an investment in seamless automation, precision, and productivity. By maximizing machine utilization, minimizing idle periods, and reducing the need for manual interventions, this advanced system stands as a testament to Deed CNC's commitment to shaping the future of manufacturing technology.

在线联系供应商

Other supplier products

| CNC TAPPING MACHINE | Vt series is a vertical drilling center independently designed and developed by our company. The product has the structural characteristics of high... | |

| GMC-SERIES GANTRY MACHINING CENTER | GMC series gantry mill for saleis the latest precision gantry boring and milling machining center jointly developed by Germany and DEED. The machin... | |

| HBC SERIES CNC HORIZONTAL BORING AND MILLING CENTER FOR SALE | HBC Series is our CNC horizontal boring and milling machine. According to the different sizes, we have HBC1116 CNC boring machine and HBC1316 CNC h... | |

| HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB | The machine tool bed adopts "mineral casting" material and technology of Germany, which guarantees DEED CNC machine tool with better performance on... | |

| VMC-SERIES VERTICAL MACHINING CENTER | As a vmc machine manufacturing company, DEED vmc cnc-series Vertical Machining Center is mainly suitable for processing complex parts such as plate... |