CNC Milling

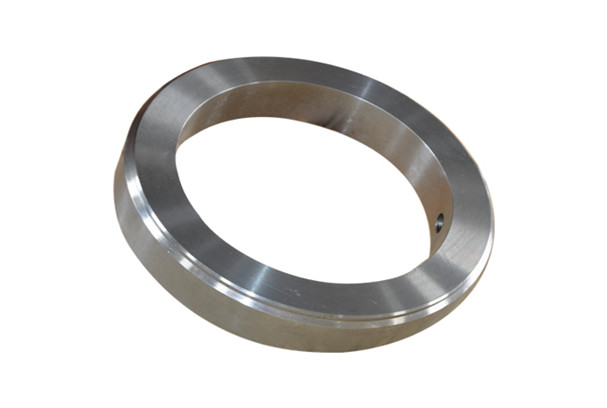

CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, multi-process concentrated part processing. The main processing objects are box parts, complex curved parts, special-shaped parts and discs, and plate parts. As a professional CNC milling company, ETCN provides the best china CNC milling service. Our services range also includes stainless steel cnc milling, cnc milling brass, mill aluminum with router.We also have applied high speed cnc millingto increase the speed of productivity.

According to the number of axes controlled, the mill axis of cnc milling for makers can be divided into 3 axis cnc mill, 4 axis cnc mill and 5 axis mill.

CNC Milling Capabilities

The comprehensive processing ability of china cnc manufacturing is strong. After the workpiece is clamped at a time, more processing contents can be completed. The processing accuracy is high. The efficiency of batch workpieces with medium processing difficulty is 5-10 times that of ordinary equipment, especially it can complete much ordinary Processing that cannot be completed by the equipment is more suitable for single-piece processing with complex shapes and high precision requirements or for small and medium batches of multiple varieties. It concentrates the functions of milling, boring, drilling, tapping, and cutting threads on one device so that it has a variety of technological means.

CNC Milling Material and Finishes

|

Machinery |

5 |

|

|

Material |

Alloys Steel |

Bronze Alloys |

|

Aluminum Alloy |

Stainless Steel |

|

|

Copper |

Carbon Steel |

|

|

Brass |

POM/PA |

|

|

Features |

Deburring |

Drilling |

|

Tapping |

Milling |

|

|

Threading |

Boring |

|

|

Grinding |

Knurling |

|

|

Maximum Dimensions |

800mm*500mm*550mm |

|

|

Milling Tolerance |

±0.005mm |

|

|

Inspection Capabilities |

CMM |

Projector |

|

Imaging Measuring Instrument |

Hardness |

|

|

Metallographic Microscope |

Non-destructive Equipment |

|

|

Automatic Thread Inspection Equipment |

||

|

Surface Finished |

Zinc Plated |

Sand Blasted |

|

Nickel Plated |

Blacking |

|

|

TD Coating |

Phosphating |

|

|

Dacromet |

Zinc-Nickel Plating |

|

|

Thread |

UNF |

UNC |

|

NPT |

SAE |

|

|

Metric |

BSPP |

|

|

BSPT |

JIS |

|

|

DIN |

G |

|

|

R |

ZG |

|

|

Certification |

ISO9001-2008 |

ISO/TS16949 |

Advantage of CNC Milling

CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, multi-process concentrated part processing. The main processing objects are box parts, complex curved parts, special-shaped parts and discs, and plate parts.

The Stamping Process Has High Production Efficiency

The stamping process has high production efficiency, convenient operation, and easy realization of mechanization and automation. This is because stamping is done by relying on punching dies and stampings. The number of strokes of a popular press can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute with high-speed CNC machining. It is possible to get a punch.

High Precision

CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, multi-process concentrated part processing. The main processing objects of CNC precision milling are box parts, complex curved parts, special-shaped parts and discs, and plate parts.

Less Waste

CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, multi-process concentrated part processing. The main processing objects are box parts, complex curved parts, special-shaped parts and discs, and plate parts.

CNC Milling FAQS

What Is A Mechanical Processing Plant And Are Its Design And Process Benchmarks The Same

Mechanical processing, although its name is short, it contains a lot of related knowledge, so if you want to have a comprehensive and in-depth understanding of mechanical processing, it takes some time and effort to achieve the goal. At the same time, I also hope that everyone will take it seriously so we can gain some professional knowledge from it.

Mechanical processing, in the view of Wuxi Tiecheng, china cnc machining factory, refers to the process of changing the external dimensions or performance of a workpiece by a mechanical device, which is called mechanical processing. In addition, if the mechanical processing is divided according to the processing method, it can be divided into two types: cutting processing and pressure processing.

In mechanical processing, if the process specification is designed, there are some design principles, which are mainly as follows: First, the designed process specification can allow parts or workpieces to have good processing quality and can reach the design drawings. The technical requirements stipulated. Second, the fabrication and machining process should have high production and processing efficiency, and the finished products obtained through processing can be used normally as soon as possible. Third, the manufacturing cost should be reduced; Fourth, the intensity of manual operations should be reduced. It also allows processing to proceed safely.

- industrial machiningthe same?

As for this question, the mechanical processing plant Wuxi Tiecheng believes that the answer is no, that is, the design benchmark and process benchmark in mechanical processing is different. Design basis refers to the basis used to determine the position of other points, lines, and areas on the part drawing. The process reference refers to the reference used by the part during processing and assembly, and it can be divided into three parts: assembly reference, measurement reference, and positioning reference.

From a professional point of view, the answer to this question is yes, and Wuxi Iron City, a mechanical processing plant, thinks so. Moreover, in addition to paying attention to the calculation of the cost of machining, it is also necessary to know how to calculate correctly, so that accurate results and correct values can be obtained, so as to avoid erroneous results and obtain erroneous values.

If you want to know the best aluminum for cnc milling, please visit our website.

As a leading CNC machining manufacturing company in China, ETCN offers high-precision CNC machining and CNCmanufacturing servicescovering different fields in China CNC grinding services like iron metal casting services, CNC machining (including plastic) services, CNC milling services, CNC punching services and CNC turning services.

在线联系供应商

Other supplier products

| Welding | Medical supplies, laser welded forming, beautiful appearance, firm, flat welding seam, no welding rod, and flux welding sheet metalis needed. As a ... | |

| Stretch Forming | Stretch forming is a technology to stretch the mental into different shaped mental parts. It also will improve the structure of the unloading part ... | |

| Bending | ETCN offers a quality CNC bending machine after laser cutting which is used for the base of the compressor motor. Different types of sheet metal be... | |

| Forging | Roll forging, upset forgingis one of the main processing methods to provide mechanical parts blank in the mechanical manufacturing industry. Throug... | |

| CNC Grinding | After CNC milling or CNC turning forming, the surface roughness and behavior tolerance requirements of products are completed by CNC grinding, and ... |