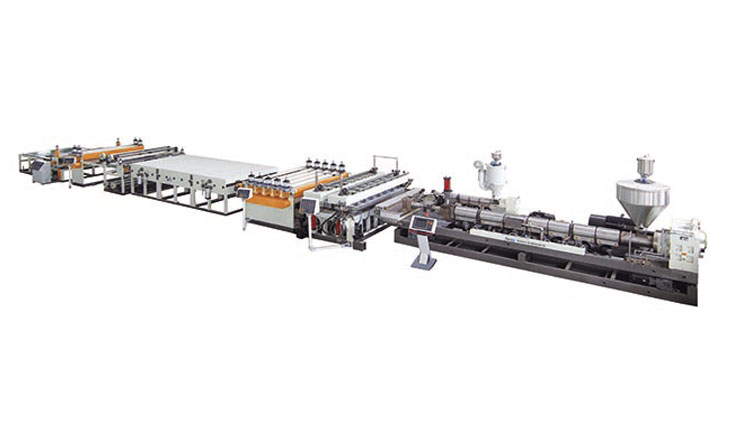

Pipe Extrusion Machine

JWELL Machinery Chinais designed and developed in a new idea, pipe and profile extrusionline produces PP pipe series, PVC pipeline series, ABS pipeline series, composite pipe series, etc., plastic pipe extrusion machineis high-yield, low energy consumption, good melt homogeneity, and long-term Running stability, modular design is a pp pipe extruderseries, providing convenience, how to save raw materials, improve automation, ensure high output rate, high quality extrusion, and pipe extrusion machine priceis very competitive for users, etc. aspects provide the perfect total solution

Types of PPPipe Extrusion Machine

Corrugated Pipe Machine

HDPE/PP/PVC horizontal type Double Wall Corrugated pipe extrusion line, Special Use Single Wall and Double-wall Corrugated Pipe Extrusion Line produced by Jwell has many patents. Full automatic control, running stable, high capacity.

HDPE Pipe Extrusion Machine

This hdpe extrusion pipe machineadopts the most advanced technology of Europe, It is a new research achievement of energy-saving production line, The product line has a good appearance and high cost performance compared to the traditional equipment. The line is higher capacity and lower tons-consumption, more precise extrusion.

Twin Screw Pvc Pipe Machine

This production line adopts special screw and mould design to make the material form easily with uniform plasticizing, high production speed, stable running, and easy operation. Suitable for pipe extrusion production such as PVC, CPVC, OPVC

PP Pipe Extruder

This Jwell self-manufactured production line adopts Europe's advanced technology with the feature of unique structure, leading configuration, high automation, and easy operation. The extruder screw adopts BM high-efficiency type with big output, good plasticizing, nice stability, and excellent reliability, Suitable for PP-R PO, PE-RT, PB, MPP, etc.

Highlights of HDPEPipe Extrusion Line

1

Founded in 1978 China's first screw JHL brandHigh extrusion efficiencyLow energy consumptionMelt temperatureExcellent melt uniformitySpecial screw design, fast heating, compared to other same type...

2

Advanced SIEMENS computer control system achieves integration and closed-loop control of the whole line, easy data analysis (energy consumption display and analysis), remote diagnosis (fast after-sale...

3

High torque precision reducer and AC frequency conversion or permanent magnet servo motor to ensure the stability and less energy consumption of long-term high extrusion production

4

Jwell make the pipe molds by herself. For HDPE pipes, with special material mold 40Cr. Beside, we can also provide a complete spare parts service for mold including die pin, die bush, and calibration ...

Products

FAQ about Pipe Extrusion Machine

Can JWELL currently produce how big size pipe extrusion lines?

Jwell plastic extrusion company PE pipe machine from extrusion line can stably extrud out a solid wall pipe of 3 meters, and the bellows can be highly squeezed out of the 1.2-meter diameter double-wall corrugated pipeline.

How to identify good or bad performance of PVC pipe?

Pipe Extrusion Machine Produce Process

1, mixed drying

The mixture of the mixed water is to obtain a well-known raw material with the color master material and mix, mix, mix, mix.

2, plasticizing extrusion

The raw material is hopped from the hopper to the extrusion line machine, transported, reduced, melted, homogenized, slowly turned from solid particles to high elastic, and then slowly became a viscous fluid (viscosity) And persistently squeeze.

3, mold forming

At a suitable temperature, the material extruded from the extruder is based on the filter plate by the rotational motion into a straight movement into the mold. After the spiral separation, the compaction is a tubular blank in the forming section and finally press the mouthoff.

4, refrigeration molding

From the mold extruded heat pipe blank in a negative pressure state, according to the type and refrigeration of the vacuum set of vacuum box, it will slowly refrigerate the pipe inside the pipe, and the overall cooling is formed.

5, cutting

Under the calculation of the wheel meter, the fixed length cutting of the pipe is completed according to the cutting machine.

6, stacked packaging

在线联系供应商

Other supplier products

| PP Hollow Sheet Extrusion Line | Jwell hollow plates are as follows: PP Hollow Building Formwork Double Out Extrusion Line: PP hollow building template the first mock exam double... | |

| Spandex Machine | Spandex is the earliest developed and most widely used variety among elastic fibers and the most mature production technology. Normally two ways... | |

| PVC Sheet Extrusion Line | The PVC sheet extrusion production line of jwell machinery chinais divided into hard sheet and plate, mainly as follows: There are two kinds of ... | |

| PET Sheet Extrusion Line | Jwell PET sheet extrusion line: pet sheet lineequipped with degassing system, The crystallization-free and drying-free exhaust PET sheet unit launc... | |

| HDPE Pipe Extrusion Machine | HDPEpipe extrusion machineproduction line adopts the most advanced technology of Europe, It is a new research achievement of energy-saving producti... |