Industrial Plastic Injection Mold

The injection molding part is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial equipment and cost-reduction.

Green Vitality has accumulated many experiences over the years in providing a full spectrum of services for custom injection plastic components that are precisely matched to industrial applications. We are capable to manufacture mechanical parts and shells, bearings, gears, screw and nuts, seals, pipe fittings, valves, pumps, connectors, adapters, and many more.

Industrial Moulds Process

To effectively control the development cost of mold building, reduce the cost of later repair molds, accelerate the progress of product development, and fully verify product performance as much as possible. In the mold development process, Industrial Product verification needs to be carried out in several stages.

PROTOTYPE SAMPLE

Before investing a lot of money in building tooling (molds), It is wise to test the invention of new ideas with a real model which is usually created by rapid prototyping techniques as per drawing, it helps to review key points such as appearance, dimensions, critical areas, performance, and assembly, then to further optimize the details at the earliest stage of product development. When verified models are made, they can be used for displaying at trade fairs or presentations to investors.

TOOLING

Green Vitality Industry is fully equipped for mold machining. After verification of the prototyping parts, we can move into the tooling process, how we design the molds is mostly depended on the project challenge, technical data for injection mold building will be created and double-checked mutually, so you clearly know how the molds will be like such as the cavity numbers, mold life, runner, surface treatment, mold size, mold weight, etc.

If you have your own injection machines, molds will be built to fill the capacity of your machines without potential problems with mass production processing.

MASS PRODUCTION

After sample parts have been thoroughly tested and approved, we can finally set up for the first batch production. Green Vitality Industry has injection machines in-house to manage the production of full volume plastic injection molding parts. In-process inspection is implemented to ensure top quality. Once production is finished, we do additional inspections such as dimension, critical surface, function, and rest specifications before shipment.

01

PROTOTYPE SAMPLE

02

TOOLING

03

MASS PRODUCTION

Advantages of Project Management for Molding Industrial Products

Industrial Injection Molding Experts

Flexible OEM service is available, Steady Engineering team provides with advice and solution to part moldability and error prevention for the overall project purpose.

Commitment to Quality

We believe in and practice the "Quality is of Prime Importance” philosophy. Well-versed manufacturing team to manage the mold machining and injection processing. QA department performs strong quality assurance in order that all products and services meet or exceed the expecting needs.

Competitive Price

With diversity in equipment capabilities and in-depth knowledge about industrial injection mold, Green Vitality is able to offer Competitive Prices for all products and services reasonably.

In-time Delivery

Professional team create and execute the most efficient schedule for respective project task, and help arrange delivery at the economical possible cost.

Information for Customized Plastic Mould Industry

FAQ

Q:

Information about injection mold

A:

Solution of the industrial injection mold and molding parts, there are different options depending on the part's purpose. And the price is subject to your specific requirements.

Hence, we summarize some important questions and information needed in order to prepare an accurate quotation for evaluation at the initial stage of your next project.

1) Part drawing of 2D / 3D, sketch or picture with detailed dimension, or physical samples.

2) Number of Mold Cavities.

3) Mold steel material to meet your planned mold life.

4) Hot runner or cold runner. If the former, what brand it is?

5) Standard of the mold spare parts (LKM, DME, HASCO, etc.).

6) Parameter of your injection machine so that we would design the mold to match well with your machine.

Q:

Information about plastic parts

A:

1) Material of plastic parts, or tell us the application and working environment, our engineers will suggest the suitable plastic material.

2) The part surface treatment.

3) The quantity for the first order. And how many parts will you be making totally?

4) The color of the injection parts.

If you haven't decided on the detailed requirement of the project yet, you are welcome to discuss it with us, and we would love to share our experiences and suggestion for reference. Green Vitality aims to solve the challenges faced by customers.

If you are looking for a reliable plastic injection manufacturer, don't hesitate to contact us!

Other supplier products

|

|

Auto Bumper Mould |

Auto Bumper Mould

The front and rear bumpers of the car are made of plastic, which not only maintains the protection function, but also has the ch... |

|

|

Home Appliance Mould |

GV Mold has rich experience in home appliance molds (such as television, refrigerators, fans, washing machines, air conditioners, and various smart... |

|

|

Car Light Mould |

Car lights are mainly used for lighting, which can be said to be the eyes of cars. Car lights are the collective name for all car lighting systems.... |

|

|

Teeth Tray Mold |

A dental impression is a mold removed from a tooth to diagnose and treat dental conditions. They are also used in forensic science. Impressions are... |

|

|

Plastic Gear Mold |

Injection molded plastic gearsis one of the most widely used transmission mechanisms in the field of instruments & meters, timers, reducers, ca... |

供应产品

Same products

|

|

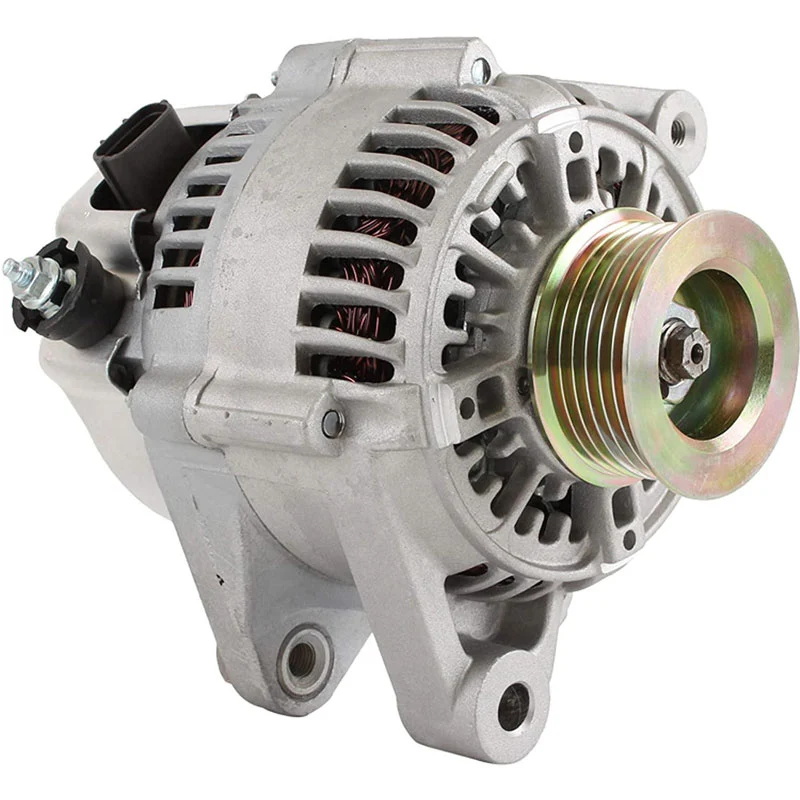

OEM Car Parts Alternator for Toyota |

卖方: Foshan Bohua Auto Parts Co., Ltd |

Automobile alternator, which is the main power supply of the automobile, is driven by the engine.... |

|

|

OEM Parts of Alternator in Car for Toyota |

卖方: Foshan Bohua Auto Parts Co., Ltd |

OEM Parts of Alternator in Carfor Toyota

Automobile alternator, which is the main power supply ... |

|

|

OEM Alternator Wholesale for Toyota |

卖方: Foshan Bohua Auto Parts Co., Ltd |

Automobile alternator wholesale, which is the main power supply of the automobile, is driven by t... |

|

|

OEM Automotive Alternator Parts for Toyota |

卖方: Foshan Bohua Auto Parts Co., Ltd |

The OEM part number refers to automotive alternator partsspecifically designed for Toyota vehicl... |

|

|

OEM Auto Parts Alternator for Toyota |

卖方: Foshan Bohua Auto Parts Co., Ltd |

Auto parts alternator, which is the main power supply of the automobile, is driven by the engine.... |