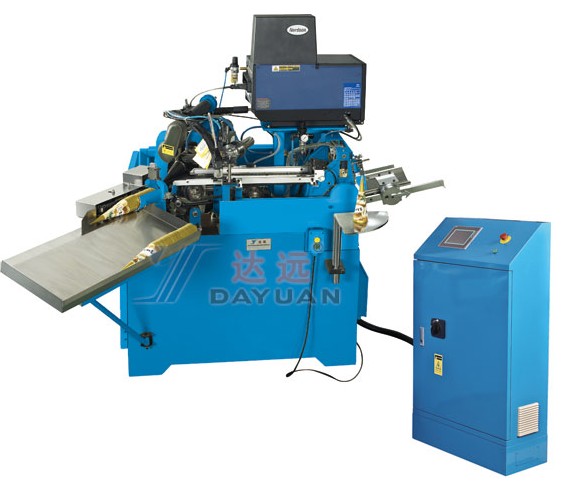

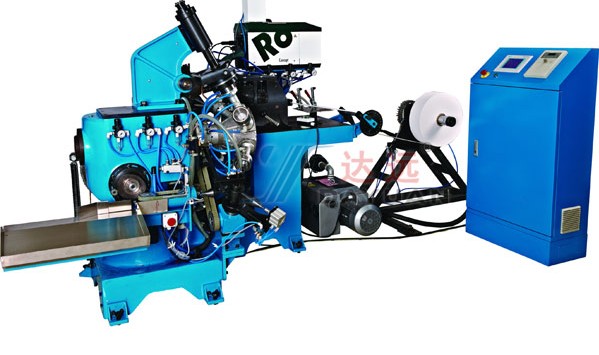

hamburger box forming machine

Working principle: A sucking nozzle sucks transfers the pre-printed and cut paper from the paper shelf to the feeding chains and then the paper is carried to shaping moulds, during which the paper is glued thermo sol. The position, length and quantity can be adjusted while in progress without stopping production. The shaped paper is discharged to collector and is piled and counted automatically. The preset piling quantity of paper is carried forward automatically when it is finished without stopping production. The Specifications of the product DYK6-B produces

1. Minimum height:100mm

2. Maximum height: 255mm

3. Angle: 15°-28° (different size products can be made with an adapted die) Characteristics

High efficiency: Continuous production in three shifts and finished products are counted automatically;The system is computerize numerically controlled systerm, touch screen control panel and thus operation is more easy and maintenance is saving. High precision parts: More endurable and longer service life. Intellectual detection: Safety protection is further strengthened and faults can be detected automatically and indicated on line. Main facility is lubricated in oil cycle and thus components is more durable. Design philosophy: High speed, high efficiency, energy saving and safe. Thermo sol-spraying mode: Adopt digital information input and data can be replaced without stopping the machine. Inexpensive. Production speed:

Produce as many as 220 pcs per minute. Raw materials:

Common paper, aluminum foil paper or dry wax paper which is not exceeding 100g/m2. Covering area: 2.5M × 2.5M Package dimensions:

(1) Length: 1.50m Width: 1.20m Height: 1.50m

(2) Length: 1.43m Width: 0.71m Height: 1.12m Weight: Gross weight 1200kgs approx. Points of considerations:

use machine of compressed air without drying may reduced service life of components and destroy the machine. Erroneous selection of materials (including papers and thermo sol) may debase the efficiency and bring the problem of quality. The printing of logo and treat with surface of papers is very important and must to test the papers before use. Wrong operation may caused quality problem and reduce efficiency.

Other supplier products

|

|

hamburger box forming machine |

ZBR, automatic paper cone cup machine is exploited exclusively by our company, and which supplies a gap of Chinese market.

This equipment is spec... |

|

|

hamburger box forming machine |

Working principle:

A sucking nozzle sucks transfers the pre-printed and cut paper from the paper shelf to the feeding chains and then the paper ... |

|

|

hamburger box forming machine |

The work principle:

Feeder transmits the pre-printed and cut cardboard from the paper shelf to the convey chain, and then sent to shaping mould. D... |

|

|

hamburger box forming machine |

The work principle:

Feeder transmits the pre-printed and cut cardboard from the paper shelf to the convey chain, and then sent to shaping mould. D... |

|

|

hamburger box forming machine |

Automatic Punching Machine

For the production of blanks from vaeious materials, e. G. Ice-cream

Cone blanks from paper/aluminium laminate, cup bla... |

供应产品

Same products