- Using the numerical simulation software to design a suitable crushing and split flow, optimize the grinding machine host and worm wheel air

- flow structure design

- Multi row and multi-layer device added to the machine to achieve multi-level material grinding

- Machine internal airflow channel and crushing area work independently

- Internal water cooling circulating device, suitable for grinding heat sensitive material (such as polyvinyl alcohol), It will not be deteriorated

- as the material temperature rised during crushing process, such as Crushed polyvinyl alcohol to produce "bubble" material and make the

- material color changed that affect the quality of products. At the same time also reduces the material flow with high rotation speed and

- friction into a ball, so that more difficult to crush.

- Installed power is small,Installed power one-fourth less than other similar models

- The pulverizing hammer and the gear ring is made of super hard alloy materials through special processing, easy-wear parts are made of

- wear-resistant processing, greatly improving the service life of the wearing parts, service life is 3-4 times than other similar models, and

- greatly reduce the iron impurities (widely used in this manner)

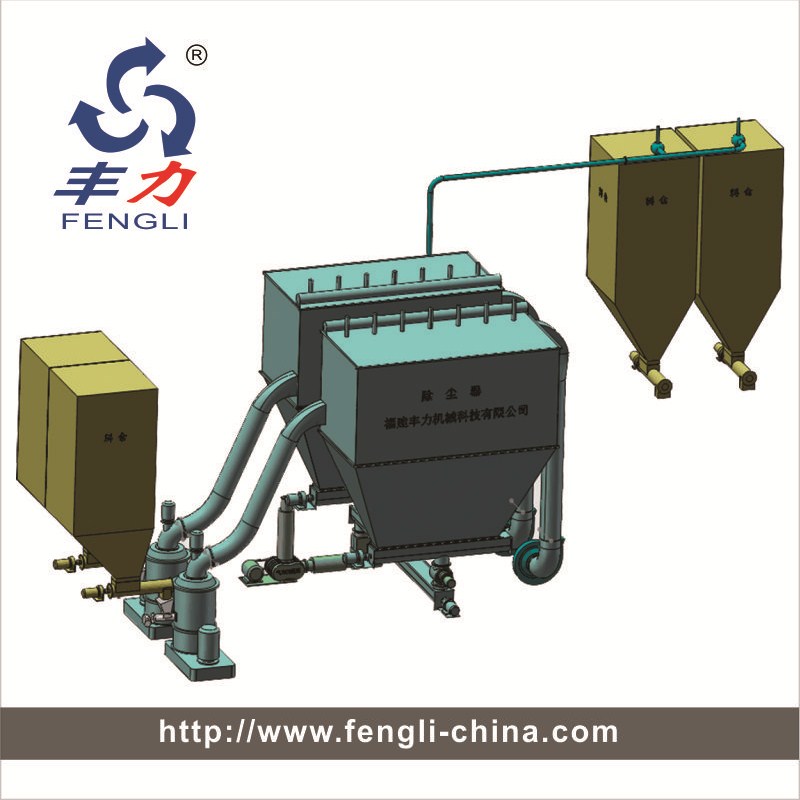

- A high degree of automation, the whole machine adopts the full closed negative pressure operation, the production environment is clean, no

- dust pollution, dust emission is less than 20mg/m3 (national environmental protection standard ≤35mg/m3), completely meet the national

- environmental protection requirements

|